Benchtop equipment offers compact, user-friendly solutions ideal for small-scale, precise tasks or research applications, while industrial-scale equipment is designed for high-volume production with robust durability and efficiency. Choosing between the two depends on the scope of the project, available space, and desired output capacity. Benchtop models allow for flexibility and cost-effectiveness, whereas industrial-scale machines emphasize power and long-term operational stability.

Table of Comparison

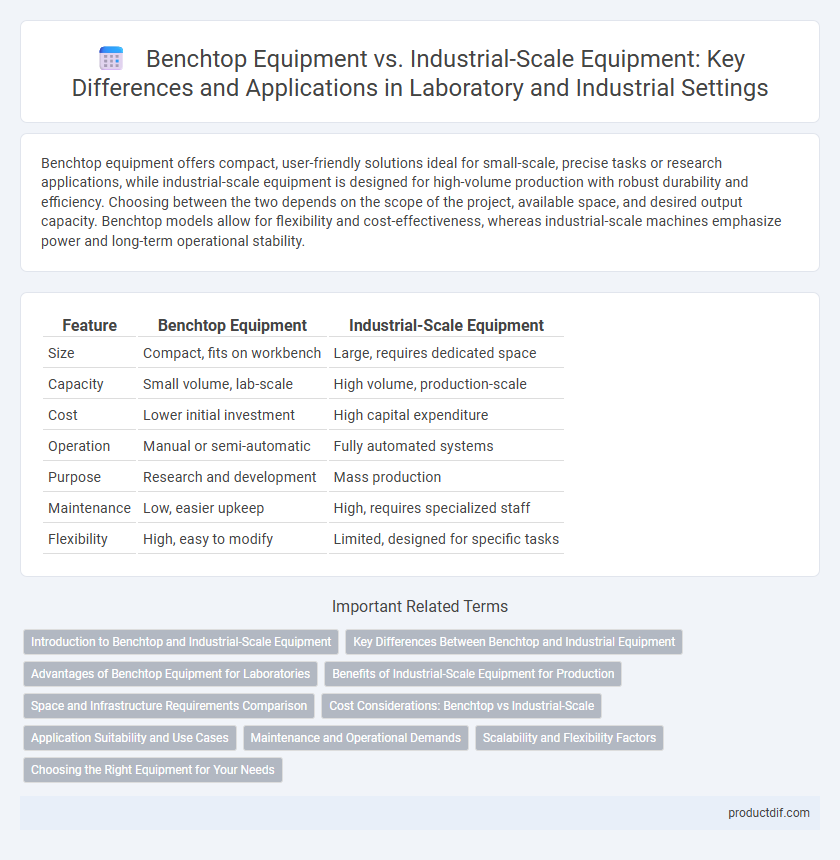

| Feature | Benchtop Equipment | Industrial-Scale Equipment |

|---|---|---|

| Size | Compact, fits on workbench | Large, requires dedicated space |

| Capacity | Small volume, lab-scale | High volume, production-scale |

| Cost | Lower initial investment | High capital expenditure |

| Operation | Manual or semi-automatic | Fully automated systems |

| Purpose | Research and development | Mass production |

| Maintenance | Low, easier upkeep | High, requires specialized staff |

| Flexibility | High, easy to modify | Limited, designed for specific tasks |

Introduction to Benchtop and Industrial-Scale Equipment

Benchtop equipment offers compact, versatile solutions ideal for laboratory experiments and small-scale testing, enabling precise control and ease of use in confined spaces. Industrial-scale equipment supports high-volume production with robust construction and advanced automation, ensuring efficiency and consistency in manufacturing processes. Both equipment types play critical roles in product development and scale-up, bridging the gap between laboratory research and full-scale industrial operations.

Key Differences Between Benchtop and Industrial Equipment

Benchtop equipment is designed for small-scale laboratory experiments, offering compact size, ease of use, and lower cost, which contrasts with industrial-scale equipment built for high-volume production, featuring robust construction and advanced automation. Key differences include throughput capacity, where benchtop systems handle minimal batch sizes suitable for R&D, while industrial equipment supports continuous processing with higher efficiency and durability. Maintenance requirements and scalability also diverge, with benchtop devices requiring simpler upkeep and limited scalability compared to the complex, scalable nature of industrial machinery tailored for extensive manufacturing operations.

Advantages of Benchtop Equipment for Laboratories

Benchtop equipment offers precise control and ease of use, making it ideal for laboratory settings where accuracy and repeatability are critical. Its compact size conserves valuable workspace and facilitates quick setup and maintenance, enhancing productivity during experiments. Lower energy consumption and cost efficiency also make benchtop models accessible for small to medium-scale research projects.

Benefits of Industrial-Scale Equipment for Production

Industrial-scale equipment offers significant advantages for production, including higher throughput, enhanced durability, and the ability to handle larger volumes continuously, which boosts operational efficiency. Unlike benchtop equipment, industrial-scale machinery is designed to meet rigorous manufacturing standards, ensuring consistent product quality and compliance with industry regulations. Moreover, integrating automated processes in industrial-scale equipment reduces labor costs and minimizes human error, optimizing production scalability and overall profitability.

Space and Infrastructure Requirements Comparison

Benchtop equipment requires significantly less space, making it ideal for laboratories and small-scale operations with limited infrastructure. In contrast, industrial-scale equipment demands extensive floor area, robust power supply, and advanced ventilation systems to accommodate high-capacity production. Understanding these space and infrastructure requirements is crucial for optimizing workflow efficiency and reducing operational costs in manufacturing environments.

Cost Considerations: Benchtop vs Industrial-Scale

Benchtop equipment typically incurs lower upfront costs and maintenance expenses compared to industrial-scale machinery, making it ideal for small-scale or prototype projects. Industrial-scale equipment, while requiring substantial initial capital investment, offers higher efficiency and reduced per-unit production costs in large-volume manufacturing. Evaluating cost considerations involves balancing budget constraints with production goals to determine the most economically viable equipment scale.

Application Suitability and Use Cases

Benchtop equipment is ideal for laboratories and small-scale research, offering precision and compactness for tasks like sample analysis, quality control, and prototyping. Industrial-scale equipment suits high-volume production environments, handling tasks such as manufacturing, bulk processing, and continuous operation with greater durability and capacity. Application suitability hinges on scale, throughput requirements, and the complexity of operations, with benchtop devices excelling in detailed testing and industrial equipment driving mass production efficiency.

Maintenance and Operational Demands

Benchtop equipment typically requires less maintenance due to its smaller size and simpler design, enabling easier access to components and quicker troubleshooting. Industrial-scale equipment demands rigorous and scheduled maintenance protocols to ensure continuous operation, often involving specialized technicians and extensive downtime planning. Operationally, benchtop units are user-friendly with lower energy consumption, whereas industrial-scale machinery necessitates advanced training and robust infrastructure to handle higher capacity and complex processes.

Scalability and Flexibility Factors

Benchtop equipment offers high flexibility for small-scale experiments and prototyping, enabling quick adjustments and easy integration into laboratory workflows. Industrial-scale equipment excels in scalability, designed to handle large volumes and continuous production with consistent performance and reliability. Balancing scalability and flexibility is crucial when selecting equipment to meet evolving process demands and production targets.

Choosing the Right Equipment for Your Needs

Benchtop equipment offers compact size and affordability, making it ideal for small-scale experiments or pilot testing with limited space. Industrial-scale equipment provides high capacity and automation suited for large production volumes and continuous operation. Selecting the right equipment depends on factors like production capacity, budget constraints, available space, and process complexity to optimize efficiency and cost-effectiveness.

Benchtop Equipment vs Industrial-Scale Equipment Infographic

productdif.com

productdif.com