Fiber optic sensors offer high sensitivity and immunity to electromagnetic interference, making them ideal for precise measurements in harsh environments. Infrared sensors detect heat and motion by capturing infrared radiation, providing efficient non-contact monitoring but with limited accuracy in complex conditions. Both sensors serve distinct purposes, with fiber optic sensors excelling in durability and precision, while infrared sensors prioritize ease of use and quick detection.

Table of Comparison

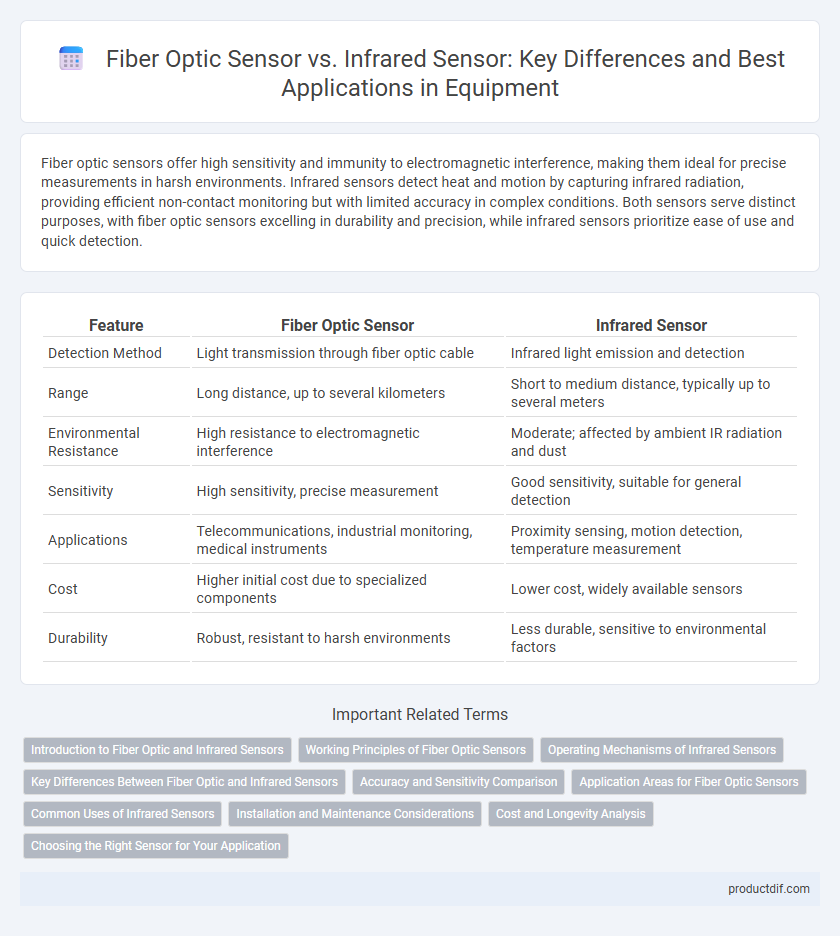

| Feature | Fiber Optic Sensor | Infrared Sensor |

|---|---|---|

| Detection Method | Light transmission through fiber optic cable | Infrared light emission and detection |

| Range | Long distance, up to several kilometers | Short to medium distance, typically up to several meters |

| Environmental Resistance | High resistance to electromagnetic interference | Moderate; affected by ambient IR radiation and dust |

| Sensitivity | High sensitivity, precise measurement | Good sensitivity, suitable for general detection |

| Applications | Telecommunications, industrial monitoring, medical instruments | Proximity sensing, motion detection, temperature measurement |

| Cost | Higher initial cost due to specialized components | Lower cost, widely available sensors |

| Durability | Robust, resistant to harsh environments | Less durable, sensitive to environmental factors |

Introduction to Fiber Optic and Infrared Sensors

Fiber optic sensors utilize light signals transmitted through optical fibers to detect changes in temperature, pressure, or strain with high sensitivity and immunity to electromagnetic interference. Infrared sensors detect infrared radiation emitted or reflected by objects, enabling non-contact temperature measurement and motion detection. Both sensor types serve critical roles in automation, safety, and environmental monitoring, with fiber optic sensors excelling in harsh environments and infrared sensors providing rapid thermal response.

Working Principles of Fiber Optic Sensors

Fiber optic sensors operate by transmitting light through optical fibers and detecting changes in light properties such as intensity, phase, wavelength, or polarization caused by physical parameters like temperature, pressure, or strain. Unlike infrared sensors that detect emitted or reflected infrared radiation from objects, fiber optic sensors rely on the modulation of light signals within the fiber medium to capture precise measurements. Their immunity to electromagnetic interference and ability to function in harsh environments make them ideal for industrial and medical applications.

Operating Mechanisms of Infrared Sensors

Infrared sensors operate by detecting infrared radiation emitted or reflected by objects, converting this energy into electrical signals for analysis. These sensors use photodiodes or thermopiles to capture temperature differences and motion changes in their environment. Unlike fiber optic sensors that rely on light transmission through optical fibers, infrared sensors function through thermal energy detection, making them ideal for motion detection, temperature measurement, and night vision applications.

Key Differences Between Fiber Optic and Infrared Sensors

Fiber optic sensors utilize light transmitted through fiber optic cables to detect changes in light intensity, offering high sensitivity, immunity to electromagnetic interference, and suitability for harsh environments. Infrared sensors detect infrared radiation emitted or reflected by objects, enabling temperature measurement and motion detection with faster response times but susceptibility to ambient light interference. Key differences include fiber optic sensors' superior precision in distance and refractive index measurements versus infrared sensors' effectiveness in thermal monitoring and object detection.

Accuracy and Sensitivity Comparison

Fiber optic sensors exhibit superior accuracy and sensitivity compared to infrared sensors due to their ability to detect minute changes in light transmission and phase shifts. These sensors provide high precision in harsh environments with minimal signal loss, making them ideal for applications requiring exact measurements. Infrared sensors typically offer faster response times but often suffer from lower sensitivity and increased susceptibility to environmental interference.

Application Areas for Fiber Optic Sensors

Fiber optic sensors excel in telecommunications, medical diagnostics, and industrial automation due to their high sensitivity to light and resistance to electromagnetic interference. These sensors are widely used in oil and gas pipeline monitoring, structural health monitoring of bridges, and precise temperature sensing in hazardous environments. Their ability to function in extreme conditions and provide real-time data makes them indispensable in aerospace, robotics, and environmental monitoring applications.

Common Uses of Infrared Sensors

Infrared sensors are commonly used in motion detection systems, temperature measurement, and night vision equipment due to their ability to detect heat signatures and changes in infrared radiation. These sensors are essential in industrial automation for object detection, security systems for intruder alerts, and consumer electronics like remote controls. Their non-contact sensing capability makes them ideal for applications requiring precise, real-time monitoring without physical interference.

Installation and Maintenance Considerations

Fiber optic sensors require precise alignment and clean installation environments to maintain signal integrity, often necessitating specialized connectors and protective cabling to prevent damage. Infrared sensors typically offer easier installation with fewer alignment constraints but may require regular cleaning to remove dust and debris that can interfere with signal accuracy. Maintenance for fiber optic sensors focuses on ensuring fiber cleanliness and connector condition, while infrared sensors demand frequent inspection of optical surfaces and sensor housing for environmental contamination.

Cost and Longevity Analysis

Fiber optic sensors generally offer higher initial costs due to advanced materials and precise installation requirements, while infrared sensors tend to be more affordable upfront. Fiber optic sensors provide superior longevity and durability, resistant to electromagnetic interference and harsh environmental conditions, resulting in lower maintenance expenses over time. Infrared sensors may require more frequent replacements and calibration, potentially increasing total operational costs despite their lower initial investment.

Choosing the Right Sensor for Your Application

Fiber optic sensors excel in environments requiring high precision and immunity to electromagnetic interference, making them ideal for medical, telecommunications, and industrial automation applications. Infrared sensors offer robust performance in detecting heat and motion, commonly used in security systems, environmental monitoring, and non-contact temperature measurement. Selecting the right sensor depends on factors such as sensitivity requirements, environmental conditions, and the specific detection task, ensuring optimal accuracy and reliability for the application.

Fiber optic sensor vs infrared sensor Infographic

productdif.com

productdif.com