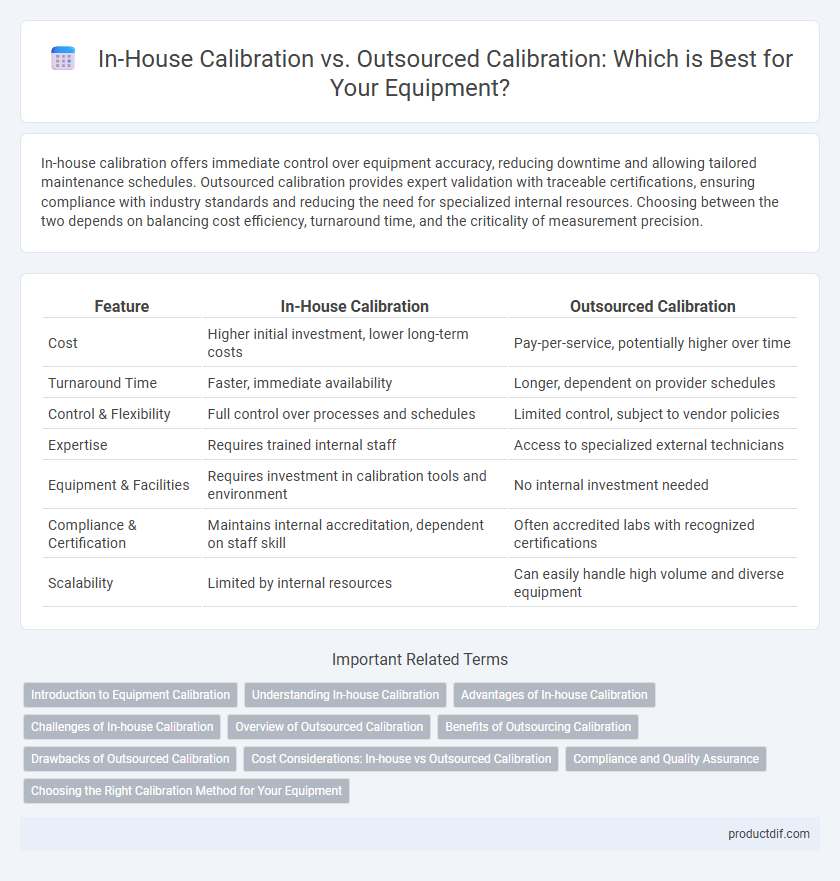

In-house calibration offers immediate control over equipment accuracy, reducing downtime and allowing tailored maintenance schedules. Outsourced calibration provides expert validation with traceable certifications, ensuring compliance with industry standards and reducing the need for specialized internal resources. Choosing between the two depends on balancing cost efficiency, turnaround time, and the criticality of measurement precision.

Table of Comparison

| Feature | In-House Calibration | Outsourced Calibration |

|---|---|---|

| Cost | Higher initial investment, lower long-term costs | Pay-per-service, potentially higher over time |

| Turnaround Time | Faster, immediate availability | Longer, dependent on provider schedules |

| Control & Flexibility | Full control over processes and schedules | Limited control, subject to vendor policies |

| Expertise | Requires trained internal staff | Access to specialized external technicians |

| Equipment & Facilities | Requires investment in calibration tools and environment | No internal investment needed |

| Compliance & Certification | Maintains internal accreditation, dependent on staff skill | Often accredited labs with recognized certifications |

| Scalability | Limited by internal resources | Can easily handle high volume and diverse equipment |

Introduction to Equipment Calibration

Equipment calibration ensures measurement accuracy and optimal performance by systematically adjusting instruments to meet predefined standards. In-house calibration allows immediate access and control over calibration schedules, promoting rapid turnaround and consistent compliance with internal quality protocols. Outsourced calibration leverages specialized expertise and accredited laboratories, offering traceable certifications and advanced testing capabilities essential for critical applications.

Understanding In-house Calibration

In-house calibration involves performing equipment adjustments and measurements within an organization using dedicated tools and trained personnel, ensuring immediate control and faster turnaround times. This method enhances accuracy by allowing regular monitoring and quick detection of deviations, supporting consistent operational efficiency. Utilizing proprietary calibration protocols aligns with specific production requirements, reducing downtime and maintaining compliance with industry standards.

Advantages of In-house Calibration

In-house calibration offers precise control over equipment accuracy and immediate correction, reducing downtime and enhancing productivity. It enables tailored calibration schedules that align with specific operational needs, ensuring consistent compliance with industry standards. Cost savings emerge from eliminating third-party service fees and minimizing shipping risks, making in-house calibration a strategic investment for quality assurance.

Challenges of In-house Calibration

In-house calibration faces challenges such as high initial investment in specialized equipment and the need for skilled technicians to maintain accuracy standards. Maintaining compliance with industry regulations requires continuous training and frequent equipment upgrades, increasing operational costs. Limited calibration scope and potential bias can affect measurement reliability compared to third-party accredited laboratories.

Overview of Outsourced Calibration

Outsourced calibration involves partnering with specialized third-party laboratories equipped with advanced technology and certified standards to ensure precise measurement accuracy. This approach reduces the need for in-house technical expertise and investment in expensive calibration instruments, providing scalability and compliance with industry regulations such as ISO/IEC 17025. Many industries prefer outsourced calibration to maintain quality assurance while optimizing operational efficiency and minimizing downtime.

Benefits of Outsourcing Calibration

Outsourcing calibration offers access to specialized expertise and state-of-the-art equipment, ensuring higher accuracy and compliance with industry standards. It reduces the need for investing in costly calibration tools and ongoing staff training, resulting in significant cost savings for the company. Leveraging third-party calibration services also minimizes downtime, as equipment is serviced by professionals following strict turnaround times.

Drawbacks of Outsourced Calibration

Outsourced calibration often leads to extended equipment downtime due to shipping and waiting periods, impacting overall productivity. There is a risk of confidentiality breaches when sensitive data or proprietary equipment details are handled externally. Furthermore, reliance on third-party calibrators can result in inconsistent service quality and limited immediate control over calibration scheduling.

Cost Considerations: In-house vs Outsourced Calibration

In-house calibration requires significant upfront investment in specialized equipment, trained personnel, and ongoing maintenance costs, making it cost-effective primarily for high-frequency calibration needs. Outsourced calibration typically involves a pay-per-service model, eliminating capital expenses and reducing indirect costs such as staff training and equipment depreciation. Businesses must evaluate calibration frequency, accuracy requirements, and budget constraints to determine the most economically viable calibration strategy.

Compliance and Quality Assurance

In-house calibration offers greater control over compliance with industry standards and ensures immediate quality assurance through direct oversight and tailored processes. Outsourced calibration might meet standardized certifications but can introduce delays and risks related to inconsistent quality or miscommunication. Maintaining compliance and high-quality calibration results depends on choosing between the reliability of internal resources versus the scalability of specialized external providers.

Choosing the Right Calibration Method for Your Equipment

In-house calibration offers control, faster turnaround, and customization tailored to specific equipment, making it ideal for companies with frequent calibration needs and specialized instruments. Outsourced calibration provides access to expert technicians, advanced technology, and accreditation compliance, which is beneficial for maintaining industry standards and reducing internal resource strain. Evaluating factors such as equipment complexity, calibration frequency, cost implications, and required accuracy helps determine the most effective calibration method for your operations.

In-house calibration vs outsourced calibration Infographic

productdif.com

productdif.com