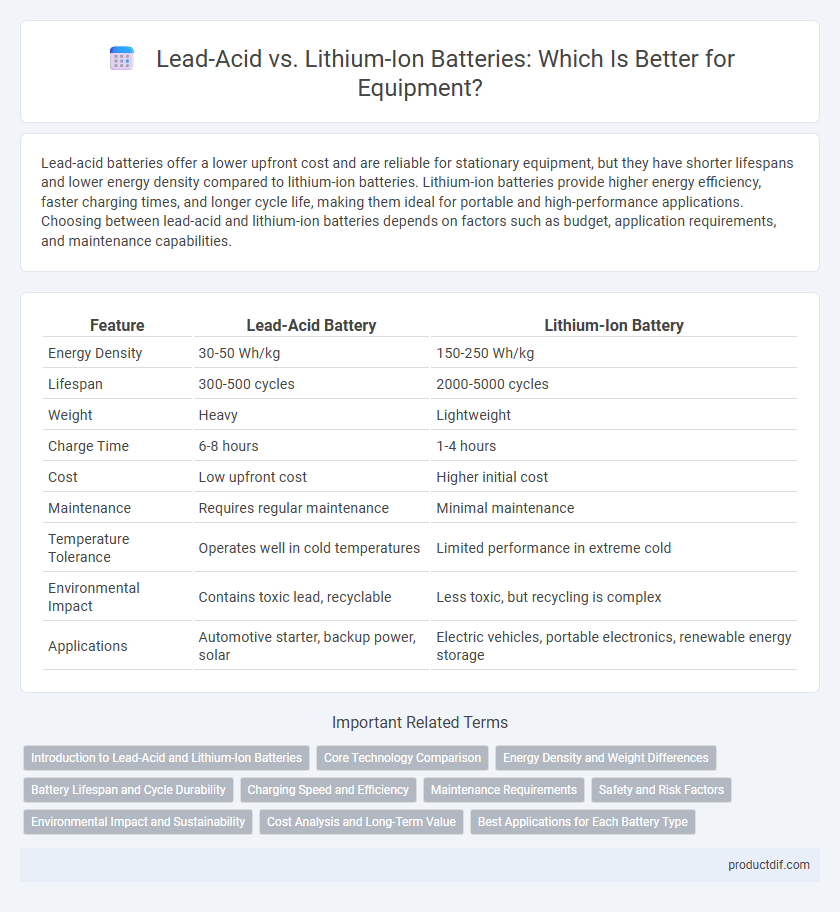

Lead-acid batteries offer a lower upfront cost and are reliable for stationary equipment, but they have shorter lifespans and lower energy density compared to lithium-ion batteries. Lithium-ion batteries provide higher energy efficiency, faster charging times, and longer cycle life, making them ideal for portable and high-performance applications. Choosing between lead-acid and lithium-ion batteries depends on factors such as budget, application requirements, and maintenance capabilities.

Table of Comparison

| Feature | Lead-Acid Battery | Lithium-Ion Battery |

|---|---|---|

| Energy Density | 30-50 Wh/kg | 150-250 Wh/kg |

| Lifespan | 300-500 cycles | 2000-5000 cycles |

| Weight | Heavy | Lightweight |

| Charge Time | 6-8 hours | 1-4 hours |

| Cost | Low upfront cost | Higher initial cost |

| Maintenance | Requires regular maintenance | Minimal maintenance |

| Temperature Tolerance | Operates well in cold temperatures | Limited performance in extreme cold |

| Environmental Impact | Contains toxic lead, recyclable | Less toxic, but recycling is complex |

| Applications | Automotive starter, backup power, solar | Electric vehicles, portable electronics, renewable energy storage |

Introduction to Lead-Acid and Lithium-Ion Batteries

Lead-acid batteries, developed in the 19th century, are widely used for their reliability, low cost, and high surge current capabilities, making them ideal for automotive starters and backup power systems. Lithium-ion batteries, emerging in the late 20th century, offer higher energy density, longer cycle life, and faster charging, revolutionizing portable electronics and electric vehicles. Both battery types serve critical roles in energy storage, with lead-acid batteries favored for stationary and heavy-duty applications, while lithium-ion dominates mobile and high-performance sectors.

Core Technology Comparison

Lead-acid batteries utilize lead dioxide and sponge lead plates submerged in sulfuric acid, offering a mature and cost-effective energy storage solution with lower energy density and shorter cycle life. Lithium-ion batteries feature advanced lithium metal oxide cathodes and graphite anodes, delivering higher energy density, longer lifespan, and faster charging capabilities through complex electrochemical intercalation mechanisms. The core technology difference lies in material chemistry and ion transport efficiency, resulting in lithium-ion batteries outperforming lead-acid in weight, lifecycle, and energy efficiency for modern equipment applications.

Energy Density and Weight Differences

Lead-acid batteries typically have an energy density of around 30-50 Wh/kg, making them heavier and bulkier compared to lithium-ion batteries, which offer energy densities between 150-250 Wh/kg. The higher energy density of lithium-ion batteries significantly reduces overall equipment weight, enhancing portability and performance in applications requiring compact power sources. Weight savings achieved with lithium-ion technology lead to increased efficiency and longer runtimes in equipment relying on battery power.

Battery Lifespan and Cycle Durability

Lead-acid batteries typically offer a lifespan of 3 to 5 years with around 300 to 500 charge-discharge cycles, whereas lithium-ion batteries can last 8 to 15 years and support 2,000 to 5,000 cycles. The cycle durability of lithium-ion batteries is significantly higher due to advanced chemical stability and reduced degradation during repeated cycling. This extended lifespan and superior cycle performance make lithium-ion batteries more cost-effective and reliable for long-term equipment operation.

Charging Speed and Efficiency

Lead-acid batteries typically require 8 to 16 hours to reach full charge, resulting in lower charging efficiency compared to lithium-ion batteries, which can achieve full charge within 1 to 4 hours due to advanced chemistry and faster ion mobility. Lithium-ion technology offers higher energy density and reduced charge losses, leading to improved overall efficiency and longer cycle life. In industrial and portable equipment applications, lithium-ion batteries deliver superior quick-charging capabilities and energy efficiency, making them a preferred choice over traditional lead-acid options.

Maintenance Requirements

Lead-acid batteries require regular maintenance including checking electrolyte levels, cleaning terminals, and equalizing charges to prevent sulfation and extend lifespan. Lithium-ion batteries demand minimal maintenance, typically only periodic calibration and monitoring of battery management systems to optimize performance and safety. The lower maintenance needs of lithium-ion batteries reduce downtime and total cost of ownership in equipment applications.

Safety and Risk Factors

Lead-acid batteries pose higher risks of acid leaks and hydrogen gas explosions due to their liquid electrolyte, demanding careful maintenance and ventilation. Lithium-ion batteries offer improved safety with solid or gel electrolytes but carry risks of thermal runaway and fire if damaged or improperly charged. Proper handling protocols and advanced battery management systems reduce hazards in both technologies, emphasizing the importance of end-user awareness in equipment safety.

Environmental Impact and Sustainability

Lead-acid batteries pose significant environmental risks due to their high levels of toxic lead and sulfuric acid, complicating disposal and recycling processes. Lithium-ion batteries offer improved sustainability with higher energy density, longer lifespan, and greater recyclability, reducing waste and resource extraction impacts. Despite higher initial environmental costs in mining lithium and cobalt, lithium-ion technology supports cleaner energy storage solutions, crucial for sustainable equipment operation.

Cost Analysis and Long-Term Value

Lead-acid batteries typically have a lower upfront cost compared to lithium-ion batteries, making them an attractive option for initial budget constraints. However, lithium-ion batteries offer a longer lifespan, higher energy density, and reduced maintenance costs, resulting in better long-term value and cost efficiency. Evaluating total cost of ownership over the battery's lifespan clearly favors lithium-ion technology despite the higher initial investment.

Best Applications for Each Battery Type

Lead-acid batteries are best suited for applications requiring low cost and high surge currents, such as automotive starters, backup power systems, and renewable energy storage with moderate cycling needs. Lithium-ion batteries excel in portable electronics, electric vehicles, and grid storage solutions that demand high energy density, lightweight design, and long cycle life. Choosing the right battery depends on factors like energy efficiency, weight constraints, and usage frequency.

Lead-acid battery vs lithium-ion battery Infographic

productdif.com

productdif.com