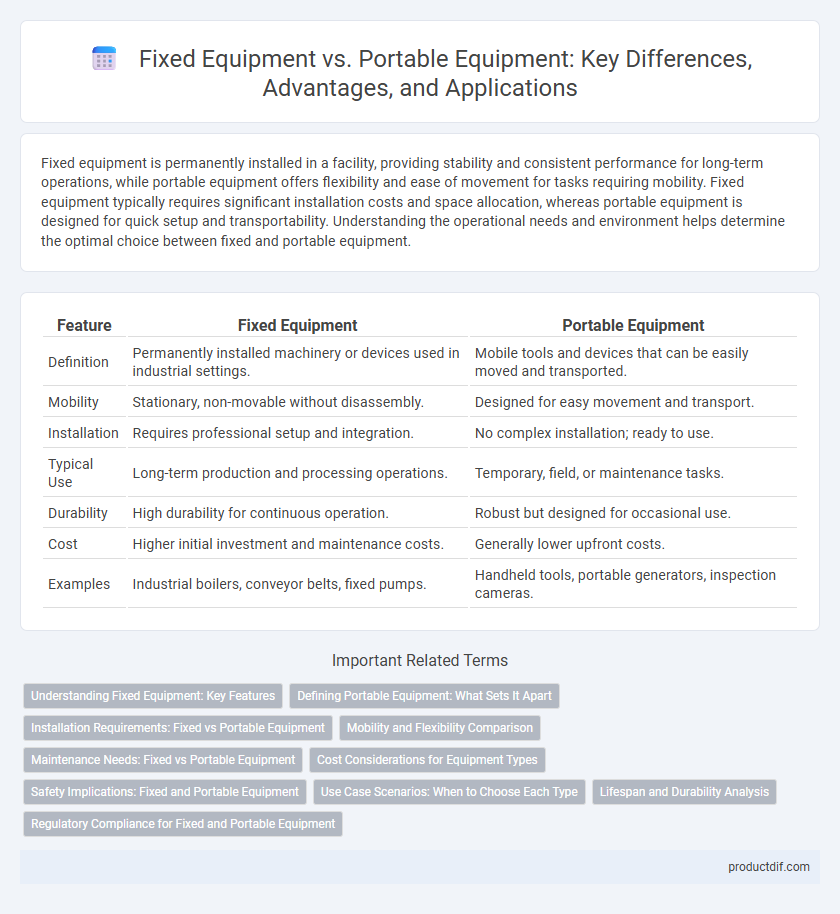

Fixed equipment is permanently installed in a facility, providing stability and consistent performance for long-term operations, while portable equipment offers flexibility and ease of movement for tasks requiring mobility. Fixed equipment typically requires significant installation costs and space allocation, whereas portable equipment is designed for quick setup and transportability. Understanding the operational needs and environment helps determine the optimal choice between fixed and portable equipment.

Table of Comparison

| Feature | Fixed Equipment | Portable Equipment |

|---|---|---|

| Definition | Permanently installed machinery or devices used in industrial settings. | Mobile tools and devices that can be easily moved and transported. |

| Mobility | Stationary, non-movable without disassembly. | Designed for easy movement and transport. |

| Installation | Requires professional setup and integration. | No complex installation; ready to use. |

| Typical Use | Long-term production and processing operations. | Temporary, field, or maintenance tasks. |

| Durability | High durability for continuous operation. | Robust but designed for occasional use. |

| Cost | Higher initial investment and maintenance costs. | Generally lower upfront costs. |

| Examples | Industrial boilers, conveyor belts, fixed pumps. | Handheld tools, portable generators, inspection cameras. |

Understanding Fixed Equipment: Key Features

Fixed equipment refers to machinery or devices that are permanently installed in a specific location within a facility, designed for continuous operation and structural integration. Key features include robust construction, high durability, and the ability to handle large-scale industrial processes with minimal relocation. Unlike portable equipment, fixed equipment typically requires specialized maintenance and is essential for maintaining production stability and safety compliance in industrial settings.

Defining Portable Equipment: What Sets It Apart

Portable equipment is defined by its mobility, designed to be easily transported and used across various locations without requiring permanent installation. Unlike fixed equipment, which is anchored in one place for continuous operation, portable equipment emphasizes versatility and convenience, often featuring lightweight materials and compact designs. This distinction enhances operational flexibility in industries such as construction, healthcare, and manufacturing, where equipment must adapt to changing environments.

Installation Requirements: Fixed vs Portable Equipment

Fixed equipment typically demands comprehensive installation requirements, including secure anchoring, precise alignment, and integration with existing infrastructure like piping and electrical systems. Portable equipment requires minimal setup, emphasizing mobility, quick deployment, and easy connection to utilities without permanent fixtures. Proper planning for fixed equipment installation ensures safety and operational efficiency, while portable devices prioritize flexibility and rapid adaptability in various environments.

Mobility and Flexibility Comparison

Fixed equipment is installed in a permanent location, offering stability and high capacity but limited mobility and flexibility. Portable equipment provides ease of movement and adaptable placement, enhancing operational flexibility in dynamic environments. Mobility advantages of portable equipment enable rapid deployment, whereas fixed equipment ensures consistent performance in fixed processes.

Maintenance Needs: Fixed vs Portable Equipment

Fixed equipment often requires scheduled preventive maintenance to ensure operational reliability and minimize downtime, given its permanent installation and integration within facility systems. Portable equipment demands more frequent inspections and functional checks due to mobility, exposure to varying environments, and higher risk of wear or damage during transport. Maintenance strategies must adapt to fixed equipment's systematic servicing protocols and portable equipment's flexible, condition-based approach to uphold safety and performance standards.

Cost Considerations for Equipment Types

Fixed equipment generally involves higher upfront installation and infrastructure costs due to permanent placement and integration requirements within a facility. Portable equipment often incurs lower initial expenses but may lead to increased maintenance and replacement costs over time because of frequent handling and potential damage. Choosing between fixed and portable equipment depends on balancing long-term capital investment with operational flexibility and lifecycle expenses.

Safety Implications: Fixed and Portable Equipment

Fixed equipment offers enhanced safety through secure installation, minimizing the risk of accidental movement or disconnection in hazardous environments. Portable equipment requires rigorous safety protocols, including regular inspections and proper handling procedures, to prevent accidents caused by mobility and variable operational conditions. Compliance with industry safety standards such as OSHA and NFPA is critical for both fixed and portable equipment to ensure workplace safety and accident prevention.

Use Case Scenarios: When to Choose Each Type

Fixed equipment is ideal for industrial environments requiring heavy-duty, stable machinery that supports continuous operations, such as manufacturing plants or processing facilities. Portable equipment suits applications demanding mobility and flexibility, including fieldwork, remote inspections, or temporary setups where ease of transport is critical. Selecting between fixed and portable equipment depends on operational needs, site constraints, and frequency of equipment relocation.

Lifespan and Durability Analysis

Fixed equipment typically boasts a longer lifespan and higher durability due to robust construction materials and permanent installation, making it suitable for continuous industrial operations. Portable equipment often sacrifices some durability and lifespan to maintain mobility and ease of use but benefits from modular designs that allow for easier maintenance and replacement. Lifespan analysis shows fixed equipment can last 15-30 years under optimal conditions, while portable equipment usually ranges from 5-10 years depending on usage and handling.

Regulatory Compliance for Fixed and Portable Equipment

Fixed equipment must comply with strict regulatory standards set by agencies such as OSHA and EPA, ensuring structural integrity and safe operation under defined conditions. Portable equipment is subject to compliance requirements emphasizing mobility, electrical safety, and environmental impact, adhering to standards like ANSI and NFPA for safe usage in diverse locations. Both categories require regular inspection, maintenance, and certification to meet industry regulations and minimize operational risks.

Fixed Equipment vs Portable Equipment Infographic

productdif.com

productdif.com