Screw fastening offers the advantage of easy assembly and disassembly, making it ideal for equipment requiring maintenance or adjustments. Rivet fastening provides a permanent, vibration-resistant joint that ensures structural integrity in high-stress applications. Choosing between screw and rivet fastening depends on factors like load requirements, accessibility, and the need for future repairs.

Table of Comparison

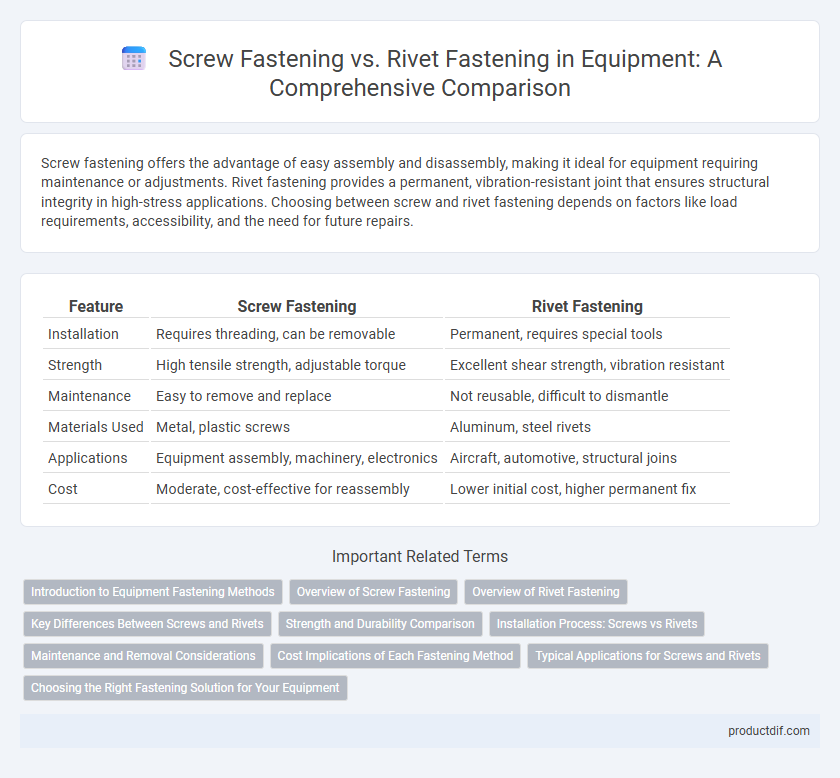

| Feature | Screw Fastening | Rivet Fastening |

|---|---|---|

| Installation | Requires threading, can be removable | Permanent, requires special tools |

| Strength | High tensile strength, adjustable torque | Excellent shear strength, vibration resistant |

| Maintenance | Easy to remove and replace | Not reusable, difficult to dismantle |

| Materials Used | Metal, plastic screws | Aluminum, steel rivets |

| Applications | Equipment assembly, machinery, electronics | Aircraft, automotive, structural joins |

| Cost | Moderate, cost-effective for reassembly | Lower initial cost, higher permanent fix |

Introduction to Equipment Fastening Methods

Screw fastening offers adjustable and reusable connections, ideal for maintenance and disassembly, while rivet fastening provides permanent, high-strength joints suited for high-vibration environments. Equipment fastening methods influence assembly efficiency, structural integrity, and material compatibility, with screws favored in precision machinery and rivets commonly used in heavy-duty applications like aerospace and automotive manufacturing. Selection depends on load requirements, environmental factors, and service life expectations to ensure optimal performance and safety.

Overview of Screw Fastening

Screw fastening utilizes threaded fasteners to join materials, offering high strength and ease of disassembly for maintenance or repairs. This method provides precise torque control and superior clamping force, making it ideal for applications requiring frequent adjustments or removals. Common in automotive, machinery, and construction industries, screw fasteners enhance reliability and reduce assembly time compared to rivet fastening.

Overview of Rivet Fastening

Rivet fastening provides a permanent, reliable joint ideal for heavy-duty equipment assemblies where vibration resistance is critical. Rivets create strong mechanical interlocks by deforming the tail, ensuring durability even under high stress and dynamic loads. Commonly used in aerospace, automotive, and structural applications, rivet fastening offers superior shear strength compared to screw fastening methods.

Key Differences Between Screws and Rivets

Screw fastening offers high precision and ease of disassembly, making it ideal for applications requiring frequent maintenance or adjustments. Rivet fastening provides superior shear strength and permanent bonding, commonly used in structural and high-vibration environments. Screws deliver adjustable clamping force, while rivets are preferred for their durability and resistance to loosening under stress.

Strength and Durability Comparison

Screw fastening generally provides higher strength and greater load-bearing capacity compared to rivet fastening, making it suitable for assemblies subjected to frequent disassembly or variable loads. Rivet fastening offers superior durability under vibration and shear stress due to its permanent fastening nature, reducing the risk of loosening over time. For long-term structural integrity, rivets ensure consistent performance, while screws allow for maintenance but may require periodic tightening.

Installation Process: Screws vs Rivets

Screw fastening involves a straightforward installation process where screws are driven into pre-drilled holes using power tools or manual drivers, allowing for easy adjustment and removal. Rivet fastening requires specialized rivet guns to deform the rivet shaft, creating a permanent joint that is highly resistant to vibration but cannot be easily undone. The screw method offers greater flexibility for maintenance, while rivet fastening provides a more robust and tamper-proof connection ideal for high-stress applications.

Maintenance and Removal Considerations

Screw fastening offers easier maintenance and removal due to its reversible design, allowing components to be disassembled without damage. Rivet fastening provides a permanent joint, making removal challenging and often requiring drilling or cutting, which can damage the materials. Choosing screw fastening enhances serviceability in equipment where frequent inspections or repairs are necessary.

Cost Implications of Each Fastening Method

Screw fastening typically incurs higher initial costs due to the price of screws and the need for precise torque application tools, but offers lower long-term expenses with easier maintenance and component replacement. Rivet fastening, while generally more economical for high-volume production given the lower cost of rivets and faster assembly, can lead to increased costs when repairs or disassembly are required. The choice between screws and rivets significantly impacts the total cost of ownership, influenced by factors such as production scale, maintenance frequency, and material compatibility.

Typical Applications for Screws and Rivets

Screw fastening is typically used in applications requiring frequent disassembly, such as machinery assemblies, automotive parts, and electronic devices, due to its ease of removal and adjustability. Rivet fastening is preferred in structural and permanent joining scenarios, including aircraft fuselage, bridges, and metal roofing, where high strength and vibration resistance are crucial. Both fastening methods serve distinct industries based on the need for maintenance flexibility or structural integrity.

Choosing the Right Fastening Solution for Your Equipment

Screw fastening offers adjustable and removable connections, making it ideal for equipment requiring frequent maintenance or part replacement. Rivet fastening provides permanent, high-strength joints suited for heavy-duty applications where vibration resistance and durability are critical. Selecting the right fastening solution depends on factors such as load capacity, accessibility, and the need for disassembly in your equipment design.

Screw fastening vs Rivet fastening Infographic

productdif.com

productdif.com