Lean manufacturing emphasizes waste reduction and process efficiency to streamline production by eliminating non-value-added activities. Agile manufacturing prioritizes flexibility and rapid response to customer demands, enabling quick adaptation to market changes and customization. Combining lean principles with agile strategies can optimize equipment utilization while maintaining responsiveness in dynamic production environments.

Table of Comparison

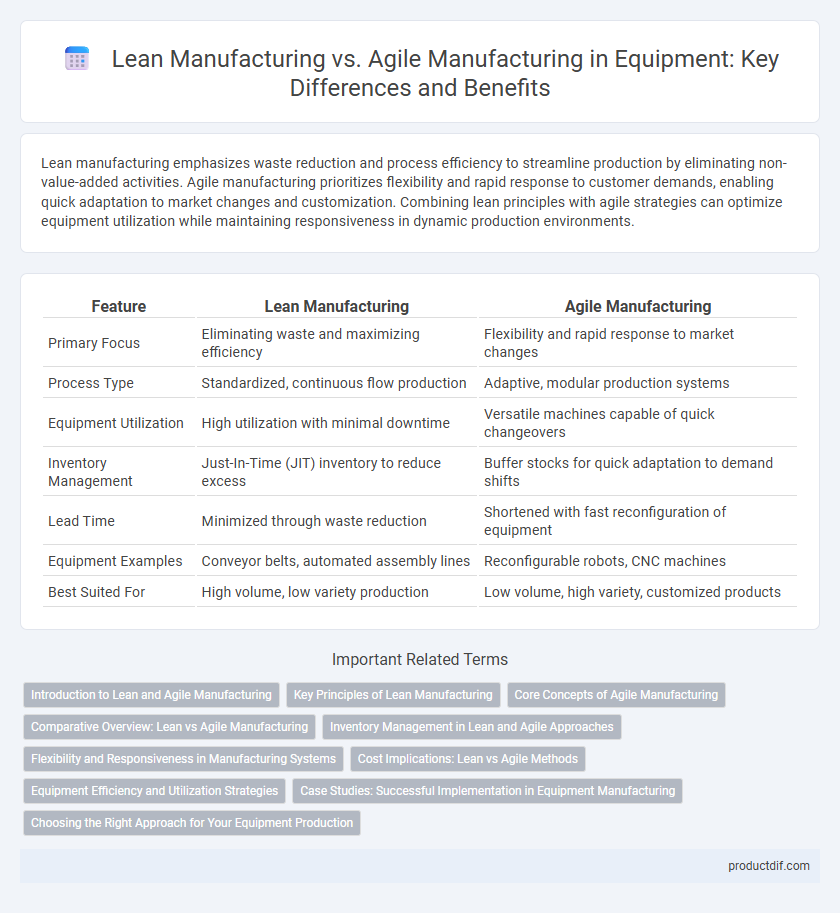

| Feature | Lean Manufacturing | Agile Manufacturing |

|---|---|---|

| Primary Focus | Eliminating waste and maximizing efficiency | Flexibility and rapid response to market changes |

| Process Type | Standardized, continuous flow production | Adaptive, modular production systems |

| Equipment Utilization | High utilization with minimal downtime | Versatile machines capable of quick changeovers |

| Inventory Management | Just-In-Time (JIT) inventory to reduce excess | Buffer stocks for quick adaptation to demand shifts |

| Lead Time | Minimized through waste reduction | Shortened with fast reconfiguration of equipment |

| Equipment Examples | Conveyor belts, automated assembly lines | Reconfigurable robots, CNC machines |

| Best Suited For | High volume, low variety production | Low volume, high variety, customized products |

Introduction to Lean and Agile Manufacturing

Lean manufacturing emphasizes waste reduction and continuous improvement to enhance production efficiency, utilizing techniques such as Just-In-Time inventory and Kaizen. Agile manufacturing prioritizes flexibility and rapid response to market changes by integrating advanced technology and cross-functional teams. Both methodologies optimize equipment utilization but diverge in focus--Lean aims for streamlined processes, while Agile adapts swiftly to customer demands.

Key Principles of Lean Manufacturing

Lean manufacturing emphasizes waste elimination, continuous improvement, and value stream mapping to optimize equipment utilization and streamline production processes. Key principles include just-in-time inventory, minimizing overproduction, and enhancing workflow efficiency to reduce lead times and operational costs. These principles drive equipment effectiveness by promoting standardized work and preventing downtime through proactive maintenance and quality control.

Core Concepts of Agile Manufacturing

Agile manufacturing emphasizes flexibility, rapid response, and customer-centric production by utilizing adaptive equipment and modular systems that can quickly adjust to changing demands. Core concepts include real-time data integration, cross-functional teams, and scalable automation, enabling manufacturers to efficiently customize products while minimizing downtime. This approach contrasts with lean manufacturing's focus on waste reduction, as agile manufacturing prioritizes responsiveness and innovation in equipment usage.

Comparative Overview: Lean vs Agile Manufacturing

Lean manufacturing emphasizes waste reduction and process efficiency through principles such as continuous improvement and just-in-time production, optimizing equipment usage to minimize downtime. Agile manufacturing prioritizes flexibility and rapid response to market changes, leveraging adaptable machinery and modular equipment setups to accommodate varying product demands. Both approaches enhance operational performance but differ in their focus: Lean targets cost efficiency with streamlined processes, while Agile aims for versatility and speed in production adjustments.

Inventory Management in Lean and Agile Approaches

Lean manufacturing emphasizes minimizing inventory levels to reduce waste and increase efficiency by implementing just-in-time (JIT) inventory management that aligns closely with production schedules. Agile manufacturing prioritizes flexibility in inventory management, maintaining buffer stocks and adaptable supply chains to quickly respond to market changes and customer demands. Both approaches optimize inventory but differ in strategy: Lean seeks continuous flow with minimal stock, while Agile balances inventory to support rapid shifts in production needs.

Flexibility and Responsiveness in Manufacturing Systems

Lean manufacturing emphasizes eliminating waste and optimizing equipment efficiency to maintain steady production flow, prioritizing flexibility through standardized processes. Agile manufacturing enhances responsiveness by integrating adaptable equipment and rapid changeover capabilities, allowing swift adjustments to market demand and customization. Both systems leverage advanced machinery and automation, but agile manufacturing focuses more on real-time adaptability while lean centers on consistent, efficient operations.

Cost Implications: Lean vs Agile Methods

Lean manufacturing significantly reduces operational costs by minimizing waste and optimizing equipment usage, leading to lower inventory carrying and production expenses. Agile manufacturing, while potentially increasing short-term costs due to flexible equipment setups and quicker changeovers, offers cost benefits through enhanced responsiveness to market demands and reduced risk of overproduction. Analyzing cost implications involves balancing lean's efficiency-driven savings with agile's adaptability-driven expenses for optimized equipment investment.

Equipment Efficiency and Utilization Strategies

Lean manufacturing maximizes equipment efficiency by minimizing waste and streamlining processes, emphasizing continuous improvement and preventive maintenance to reduce downtime. Agile manufacturing prioritizes equipment utilization flexibility, enabling rapid changeovers and adaptive setups to quickly respond to market demands and product variations. Both strategies enhance overall equipment effectiveness (OEE) but differ in balancing standardized efficiency with responsive adaptability.

Case Studies: Successful Implementation in Equipment Manufacturing

Case studies in equipment manufacturing highlight Lean manufacturing's success in reducing waste and improving process efficiency through techniques like value stream mapping and Kaizen events. Agile manufacturing demonstrates superior adaptability in responding to market changes and customization demands, utilizing modular equipment design and rapid prototyping. Companies integrating Lean and Agile principles report enhanced productivity, shorter lead times, and increased customer satisfaction in competitive equipment markets.

Choosing the Right Approach for Your Equipment Production

Selecting between Lean manufacturing and Agile manufacturing for equipment production depends on product complexity and market demand variability. Lean manufacturing emphasizes waste reduction and efficiency, ideal for high-volume, standardized equipment production. Agile manufacturing suits equipment production requiring rapid adaptation to design changes and fluctuating customer needs.

Lean manufacturing vs Agile manufacturing Infographic

productdif.com

productdif.com