Manual palletizers require significant labor input and are best suited for low-volume, simple stacking tasks, offering flexibility and lower upfront costs. Robotic palletizers provide high-speed, consistent, and precise handling for complex or high-volume operations, enhancing efficiency and reducing labor costs over time. Choosing between them depends on production scale, budget, and desired automation level.

Table of Comparison

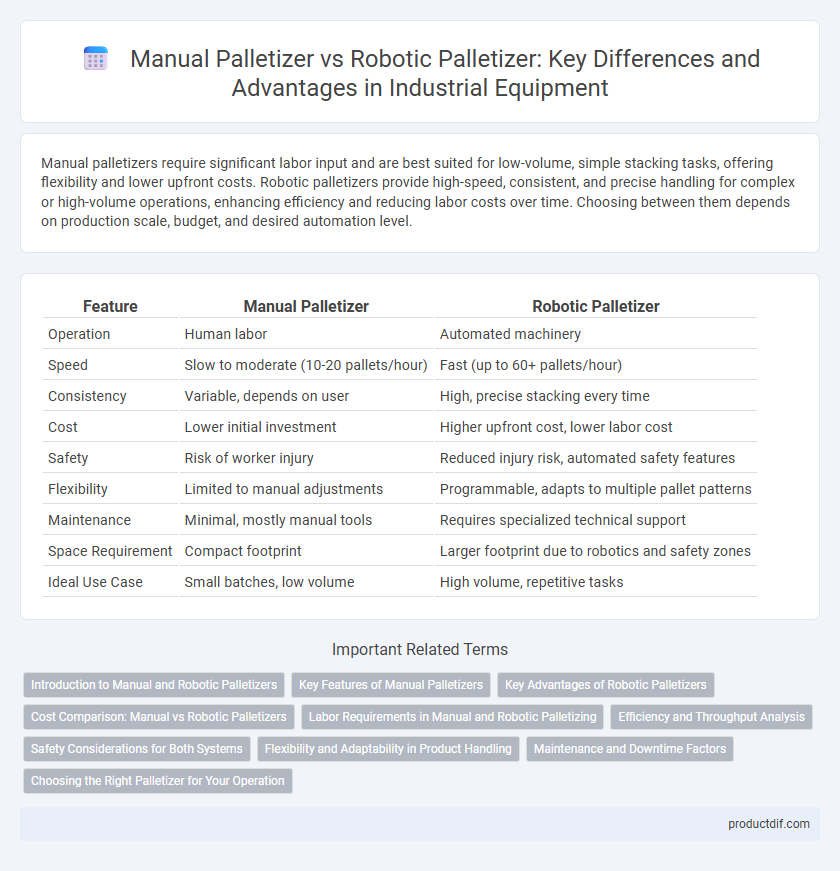

| Feature | Manual Palletizer | Robotic Palletizer |

|---|---|---|

| Operation | Human labor | Automated machinery |

| Speed | Slow to moderate (10-20 pallets/hour) | Fast (up to 60+ pallets/hour) |

| Consistency | Variable, depends on user | High, precise stacking every time |

| Cost | Lower initial investment | Higher upfront cost, lower labor cost |

| Safety | Risk of worker injury | Reduced injury risk, automated safety features |

| Flexibility | Limited to manual adjustments | Programmable, adapts to multiple pallet patterns |

| Maintenance | Minimal, mostly manual tools | Requires specialized technical support |

| Space Requirement | Compact footprint | Larger footprint due to robotics and safety zones |

| Ideal Use Case | Small batches, low volume | High volume, repetitive tasks |

Introduction to Manual and Robotic Palletizers

Manual palletizers require human operators to stack products onto pallets, offering flexibility for small-scale or varied production runs but limiting speed and consistency. Robotic palletizers utilize automated arms and programmable controls to efficiently handle high volumes with precision, reducing labor costs and operational downtime. Choosing between manual and robotic palletizing depends on production demands, budget constraints, and scalability requirements.

Key Features of Manual Palletizers

Manual palletizers offer essential features such as adjustable platforms for varying load sizes, ergonomic design to reduce operator fatigue, and simple controls that do not require extensive training. Their compact footprint makes them ideal for facilities with limited space or low-volume palletizing needs. Additionally, manual palletizers provide cost-effective solutions with minimal maintenance requirements compared to automated systems.

Key Advantages of Robotic Palletizers

Robotic palletizers offer superior flexibility, easily adapting to various product sizes and pallet patterns without the need for mechanical changes. They enhance operational efficiency by delivering faster cycle times and reducing labor costs through automation. Advanced vision systems integrated in robotic palletizers improve accuracy and minimize product damage during handling.

Cost Comparison: Manual vs Robotic Palletizers

Manual palletizers typically have lower upfront costs, often ranging from $5,000 to $20,000, making them suitable for small-scale operations with limited budgets. Robotic palletizers, with prices between $50,000 and $200,000 or more, involve higher initial investment but offer long-term savings through reduced labor costs and increased efficiency. Maintenance and operational expenses for robotic systems may be higher, but their ability to handle complex stacking patterns and continuous operation often justifies the expense in large-scale manufacturing and distribution centers.

Labor Requirements in Manual and Robotic Palletizing

Manual palletizers demand significant labor input, requiring skilled workers to stack products accurately and consistently, which can lead to increased labor costs and physical strain. Robotic palletizers drastically reduce labor requirements by automating repetitive tasks, improving efficiency and minimizing the risk of work-related injuries. This automation enhances productivity while enabling staff to focus on higher-value activities instead of manual stacking.

Efficiency and Throughput Analysis

Manual palletizers require significant labor input, leading to slower throughput rates typically ranging from 5 to 15 pallets per hour depending on operator skill and fatigue levels. Robotic palletizers deliver higher efficiency with consistent cycle times, achieving throughput rates of up to 30 to 60 pallets per hour, significantly reducing downtime and labor costs. Automated systems also provide enhanced precision and adaptability for varying product sizes, optimizing overall operational efficiency in high-volume packaging environments.

Safety Considerations for Both Systems

Manual palletizers require strict adherence to ergonomic practices and personal protective equipment to minimize the risk of musculoskeletal injuries and accidents caused by repetitive lifting or improper handling. Robotic palletizers enhance safety by reducing human exposure to heavy loads and hazardous environments, but maintenance personnel must follow lockout/tagout procedures and proper training to prevent automation-related hazards. Both systems demand comprehensive safety protocols, including routine equipment inspections and emergency stop mechanisms, to ensure operator protection and workplace compliance.

Flexibility and Adaptability in Product Handling

Manual palletizers offer high flexibility in product handling, allowing operators to adjust techniques for varying shapes, sizes, and weights of items with ease. Robotic palletizers provide advanced adaptability through programmable settings and sensors that quickly switch between product types and packaging configurations. Both systems enhance operational efficiency but differ in scalability, with robotic palletizers excelling in consistent, high-volume environments.

Maintenance and Downtime Factors

Manual palletizers require frequent maintenance due to wear on mechanical parts and operator dependency, leading to variable downtime and higher labor costs. Robotic palletizers feature predictive maintenance systems that minimize unexpected failures and reduce downtime significantly by automating fault detection. Data shows robotic systems can decrease downtime by up to 50%, boosting overall equipment effectiveness (OEE) compared to manual solutions.

Choosing the Right Palletizer for Your Operation

Manual palletizers offer cost-effective solutions for small-scale operations with lower production volumes, providing flexibility and ease of use without requiring extensive training. Robotic palletizers enhance efficiency and consistency in high-volume environments by automating repetitive tasks, reducing labor costs, and minimizing product damage through precise handling. Evaluating factors such as throughput requirements, budget constraints, and available floor space ensures the selection of the most suitable palletizing equipment for your operation.

Manual palletizer vs Robotic palletizer Infographic

productdif.com

productdif.com