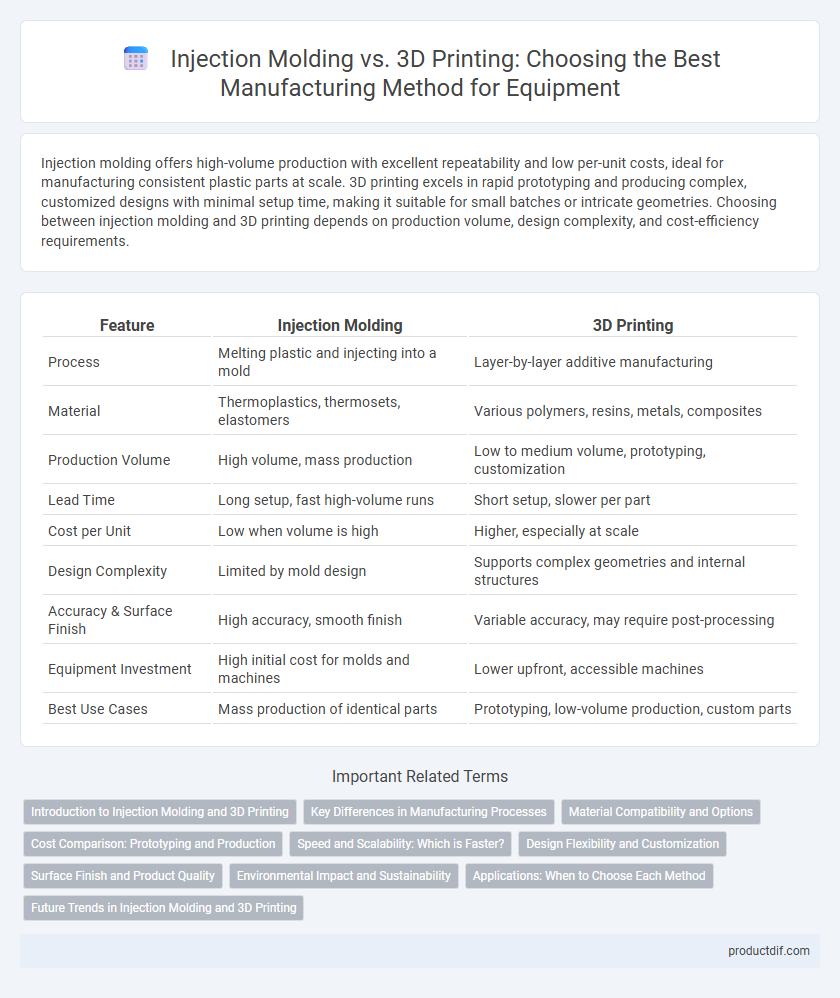

Injection molding offers high-volume production with excellent repeatability and low per-unit costs, ideal for manufacturing consistent plastic parts at scale. 3D printing excels in rapid prototyping and producing complex, customized designs with minimal setup time, making it suitable for small batches or intricate geometries. Choosing between injection molding and 3D printing depends on production volume, design complexity, and cost-efficiency requirements.

Table of Comparison

| Feature | Injection Molding | 3D Printing |

|---|---|---|

| Process | Melting plastic and injecting into a mold | Layer-by-layer additive manufacturing |

| Material | Thermoplastics, thermosets, elastomers | Various polymers, resins, metals, composites |

| Production Volume | High volume, mass production | Low to medium volume, prototyping, customization |

| Lead Time | Long setup, fast high-volume runs | Short setup, slower per part |

| Cost per Unit | Low when volume is high | Higher, especially at scale |

| Design Complexity | Limited by mold design | Supports complex geometries and internal structures |

| Accuracy & Surface Finish | High accuracy, smooth finish | Variable accuracy, may require post-processing |

| Equipment Investment | High initial cost for molds and machines | Lower upfront, accessible machines |

| Best Use Cases | Mass production of identical parts | Prototyping, low-volume production, custom parts |

Introduction to Injection Molding and 3D Printing

Injection molding is a manufacturing process that involves injecting molten material into a mold to create precise, high-volume plastic parts efficiently. 3D printing, or additive manufacturing, builds objects layer by layer directly from digital models, enabling rapid prototyping and customization with minimal material waste. While injection molding excels in mass production with consistent quality, 3D printing offers flexibility and speed for complex or low-volume designs.

Key Differences in Manufacturing Processes

Injection molding involves forcing molten material into a mold cavity to produce high-volume, consistent parts with precise tolerances, primarily using thermoplastics. In contrast, 3D printing builds objects layer-by-layer from digital models, allowing for greater design flexibility and rapid prototyping but generally slower production speeds and limited material options. Injection molding excels in mass production with low per-unit cost, while 3D printing enables customization and complexity without the need for tooling.

Material Compatibility and Options

Injection molding supports a wide range of thermoplastics, elastomers, and some composite materials, enabling mass production with consistent quality and material properties. 3D printing offers versatility in compatible materials including PLA, ABS, nylon, resin, and metal powders, allowing complex geometries and rapid prototyping but with more limited mechanical properties compared to molded parts. Material selection for injection molding favors durability and high-volume output, whereas 3D printing excels in customized, small-batch production with diverse and experimental materials.

Cost Comparison: Prototyping and Production

Injection molding entails higher initial setup costs due to mold fabrication, making it more cost-effective for large-scale production runs exceeding thousands of units. 3D printing offers lower upfront expenses and rapid prototyping capabilities, ideal for small batch production and design iterations without the need for expensive tooling. For cost-sensitive prototyping and limited quantity parts, 3D printing minimizes investment, whereas injection molding reduces per-unit costs significantly as volume increases.

Speed and Scalability: Which is Faster?

Injection molding offers significantly faster production speeds for high-volume manufacturing, producing thousands of identical parts within hours due to its automated molding process. 3D printing excels in rapid prototyping and small-scale production but is slower per unit, as each item is built layer by layer. Scalability heavily favors injection molding when mass-producing parts, while 3D printing provides flexibility for custom, low-volume runs where speed per part is less critical.

Design Flexibility and Customization

Injection molding offers limited design flexibility due to fixed molds, making it ideal for high-volume production of uniform parts. 3D printing enables extensive customization and complex geometries without additional tooling costs, supporting rapid prototyping and low-volume manufacturing. This technology allows intricate internal structures and on-demand modifications, enhancing product innovation and personalization.

Surface Finish and Product Quality

Injection molding delivers consistently smooth surface finishes with high precision, making it ideal for mass production of high-quality parts. 3D printing offers greater design flexibility but often results in rougher surfaces and layer lines that may require post-processing to meet quality standards. Advanced 3D printing technologies and material improvements are closing the gap in surface finish and product quality compared to traditional injection molding.

Environmental Impact and Sustainability

Injection molding generates substantial plastic waste during mass production but offers high energy efficiency per unit produced, while 3D printing minimizes material waste through additive processes and enables rapid prototyping with lower upfront environmental costs. The sustainability of injection molding heavily depends on the recycling of scrap material and the use of bio-based plastics, whereas 3D printing supports eco-friendly materials like biodegradable filaments and reduces transportation emissions by enabling localized manufacturing. Comparing the overall environmental impact, 3D printing excels in small-scale, customized production with lower carbon footprints, whereas injection molding is more sustainable at large scales due to its economies of scale and energy-efficient automation.

Applications: When to Choose Each Method

Injection molding excels in high-volume production of complex, durable plastic parts used in automotive, medical, and consumer electronics industries. 3D printing offers flexibility for rapid prototyping, custom designs, and low-volume manufacturing, making it ideal for product development, aerospace components, and bespoke medical implants. Choose injection molding for cost-effective mass production and 3D printing for intricate, limited-run, or highly customized parts with quick turnaround times.

Future Trends in Injection Molding and 3D Printing

Future trends in injection molding emphasize automation integration and the use of advanced materials like bio-based polymers to enhance sustainability and efficiency. 3D printing is rapidly evolving with improvements in speed, multi-material capabilities, and large-scale industrial applications, driving customization and on-demand production. Both technologies are converging through hybrid manufacturing systems, combining injection molding's precision with 3D printing's flexibility to optimize production processes.

Injection molding vs 3D printing Infographic

productdif.com

productdif.com