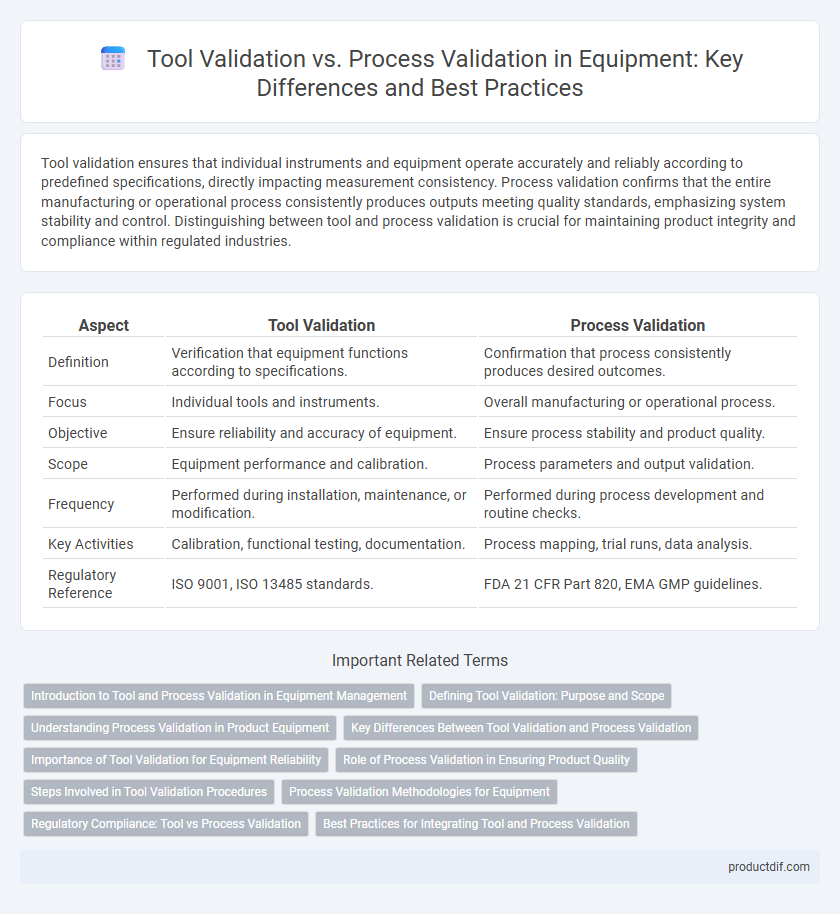

Tool validation ensures that individual instruments and equipment operate accurately and reliably according to predefined specifications, directly impacting measurement consistency. Process validation confirms that the entire manufacturing or operational process consistently produces outputs meeting quality standards, emphasizing system stability and control. Distinguishing between tool and process validation is crucial for maintaining product integrity and compliance within regulated industries.

Table of Comparison

| Aspect | Tool Validation | Process Validation |

|---|---|---|

| Definition | Verification that equipment functions according to specifications. | Confirmation that process consistently produces desired outcomes. |

| Focus | Individual tools and instruments. | Overall manufacturing or operational process. |

| Objective | Ensure reliability and accuracy of equipment. | Ensure process stability and product quality. |

| Scope | Equipment performance and calibration. | Process parameters and output validation. |

| Frequency | Performed during installation, maintenance, or modification. | Performed during process development and routine checks. |

| Key Activities | Calibration, functional testing, documentation. | Process mapping, trial runs, data analysis. |

| Regulatory Reference | ISO 9001, ISO 13485 standards. | FDA 21 CFR Part 820, EMA GMP guidelines. |

Introduction to Tool and Process Validation in Equipment Management

Tool validation ensures that individual equipment or instruments perform their intended functions accurately and reliably according to predefined specifications. Process validation encompasses the entire production or operational workflow, confirming that the combined use of tools, machinery, and procedures consistently produces desired outcomes. In equipment management, integrating both tool and process validation is critical for maintaining quality control and regulatory compliance.

Defining Tool Validation: Purpose and Scope

Tool validation ensures that individual equipment and instruments function according to specified requirements, focusing on accuracy, reliability, and performance. The purpose of tool validation is to confirm that tools produce consistent and precise outputs critical for manufacturing or testing processes. Its scope covers calibration, maintenance, and qualification of equipment to guarantee compliance with industry standards and operational specifications.

Understanding Process Validation in Product Equipment

Process validation in product equipment ensures that manufacturing systems consistently produce products meeting predetermined quality standards by verifying the entire production process under actual operating conditions. Unlike tool validation, which focuses solely on verifying the accuracy and functionality of individual instruments or equipment, process validation evaluates the integrated performance of equipment, materials, and environment to guarantee product reliability. This comprehensive approach minimizes risks, enhances compliance with regulatory requirements, and supports continuous improvement in manufacturing operations.

Key Differences Between Tool Validation and Process Validation

Tool validation verifies the accuracy and functionality of individual equipment or instruments to ensure they meet specified requirements, focusing on calibration, operational performance, and reliability. Process validation assesses the entire manufacturing or production process to confirm it consistently produces products meeting predetermined quality standards, emphasizing reproducibility, control parameters, and output quality. Key differences include the scope, with tool validation targeting specific tools, while process validation encompasses end-to-end workflow and product quality assurance.

Importance of Tool Validation for Equipment Reliability

Tool validation ensures that individual instruments and devices used in equipment consistently perform according to specified standards, directly impacting equipment reliability. Validated tools provide accurate and repeatable measurements, reducing the risk of equipment malfunctions and downtime caused by incorrect data. This process is essential for maintaining precise calibration, verifying functionality, and supporting overall equipment effectiveness in manufacturing and maintenance operations.

Role of Process Validation in Ensuring Product Quality

Process validation plays a critical role in ensuring product quality by systematically confirming that manufacturing processes consistently produce products meeting predetermined specifications. Unlike tool validation, which verifies individual equipment performance, process validation assesses the entire production workflow to identify and control variables impacting final product attributes. This comprehensive approach reduces variability, enhances reliability, and supports compliance with regulatory standards, ultimately safeguarding product efficacy and safety.

Steps Involved in Tool Validation Procedures

Tool validation involves verifying the accuracy, precision, and reliability of the equipment through calibration, functionality testing, and documentation review. The steps include initial qualification, installation verification, operational qualification, and performance qualification to ensure the tool meets required specifications. Process validation, unlike tool validation, focuses on confirming that the overall manufacturing process consistently produces products meeting predetermined quality standards.

Process Validation Methodologies for Equipment

Process validation methodologies for equipment involve systematic approaches such as Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) to ensure equipment consistently operates within predefined parameters. These methodologies emphasize validating the entire manufacturing process to guarantee product quality and compliance with regulatory standards. Unlike tool validation, which focuses on verifying individual tool functionality, process validation validates integrated system performance under actual production conditions.

Regulatory Compliance: Tool vs Process Validation

Tool validation ensures that individual equipment consistently performs according to intended technical specifications, while process validation confirms the entire production process produces products meeting quality and safety standards. Regulatory compliance requires documented evidence that both tools and processes function reliably within specified parameters, aligning with FDA and ICH guidelines. This dual validation approach mitigates risks, ensures traceability, and supports product approval in highly regulated industries such as pharmaceuticals and medical devices.

Best Practices for Integrating Tool and Process Validation

Integrating tool validation with process validation enhances manufacturing accuracy and efficiency by ensuring that both equipment performance and process parameters consistently meet quality standards. Best practices include synchronized validation planning, comprehensive documentation linking tool capabilities to process requirements, and coordinated risk assessments to identify and mitigate potential failure points. This unified approach reduces validation timelines and promotes regulatory compliance across production workflows.

Tool validation vs Process validation Infographic

productdif.com

productdif.com