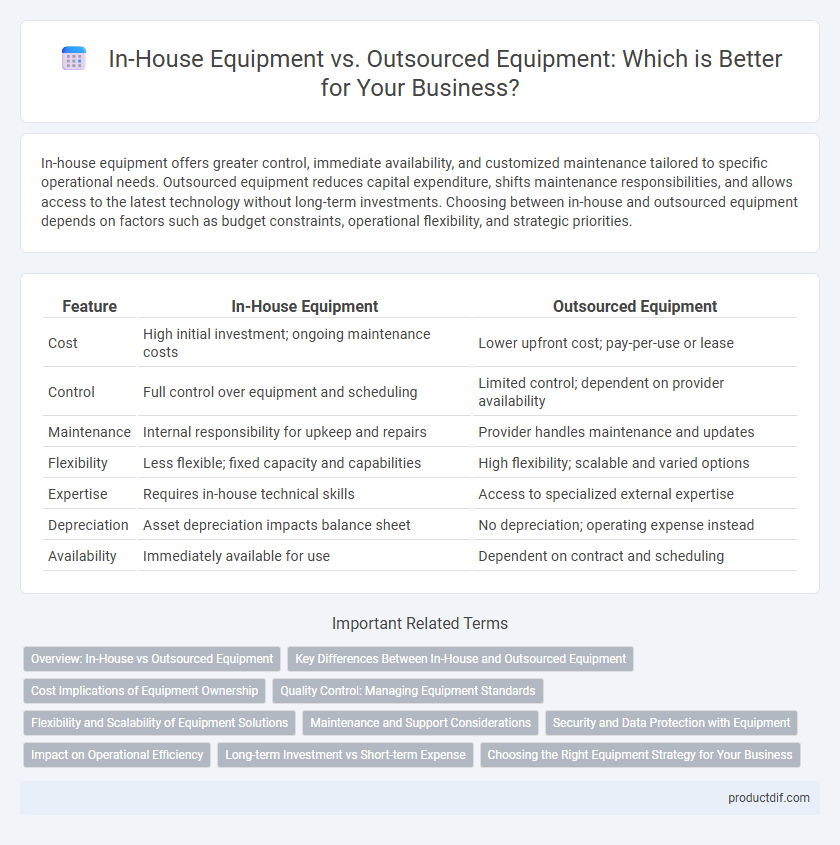

In-house equipment offers greater control, immediate availability, and customized maintenance tailored to specific operational needs. Outsourced equipment reduces capital expenditure, shifts maintenance responsibilities, and allows access to the latest technology without long-term investments. Choosing between in-house and outsourced equipment depends on factors such as budget constraints, operational flexibility, and strategic priorities.

Table of Comparison

| Feature | In-House Equipment | Outsourced Equipment |

|---|---|---|

| Cost | High initial investment; ongoing maintenance costs | Lower upfront cost; pay-per-use or lease |

| Control | Full control over equipment and scheduling | Limited control; dependent on provider availability |

| Maintenance | Internal responsibility for upkeep and repairs | Provider handles maintenance and updates |

| Flexibility | Less flexible; fixed capacity and capabilities | High flexibility; scalable and varied options |

| Expertise | Requires in-house technical skills | Access to specialized external expertise |

| Depreciation | Asset depreciation impacts balance sheet | No depreciation; operating expense instead |

| Availability | Immediately available for use | Dependent on contract and scheduling |

Overview: In-House vs Outsourced Equipment

In-house equipment offers complete control over maintenance schedules, customization, and immediate availability, often leading to enhanced operational efficiency. Outsourced equipment reduces upfront capital expenditure and shifts maintenance responsibility to third-party providers, allowing businesses to scale resources flexibly. Choosing between in-house and outsourced equipment depends on factors such as cost management, operational complexity, and long-term strategic goals.

Key Differences Between In-House and Outsourced Equipment

In-house equipment offers direct control over maintenance, customization, and immediate availability, ensuring alignment with specific operational needs. Outsourced equipment reduces capital expenditure and transfers maintenance responsibilities to the service provider, enhancing flexibility and scalability. Key differences include cost structure, control, maintenance responsibilities, and response time to equipment issues.

Cost Implications of Equipment Ownership

In-house equipment ownership entails higher upfront capital expenditures, including purchase, maintenance, and depreciation costs, whereas outsourced equipment shifts these financial burdens to the service provider through rental or leasing fees. Managing equipment internally can lead to unpredictable expenses related to repairs and technological obsolescence, while outsourcing offers predictable budgeting but may involve premium rates over long-term use. Cost analysis should factor in asset lifecycle, utilization rates, and opportunity costs to determine the most financially effective equipment strategy.

Quality Control: Managing Equipment Standards

In-house equipment allows for direct oversight and stricter adherence to quality control standards, ensuring consistent performance and timely maintenance. Outsourced equipment requires rigorous vendor selection and continuous monitoring to meet predefined quality benchmarks and avoid disruptions. Establishing comprehensive inspection protocols and clear communication channels enhances the effectiveness of managing equipment standards across both models.

Flexibility and Scalability of Equipment Solutions

In-house equipment offers direct control and customization, enabling rapid adjustments to meet specific operational needs while maintaining data security. Outsourced equipment solutions provide superior scalability, allowing businesses to quickly access advanced technology and expand capacity without significant capital investment. Combining both approaches can optimize flexibility and scalability, balancing immediate control with long-term growth potential.

Maintenance and Support Considerations

In-house equipment maintenance allows for immediate response and tailored support, ensuring minimal downtime and consistent operational control. Outsourced equipment maintenance offers access to specialized expertise and reduces internal resource allocation but may involve longer response times and dependency on external providers. Evaluating cost-effectiveness, skill availability, and criticality of equipment helps determine the optimal balance between in-house support and outsourcing.

Security and Data Protection with Equipment

In-house equipment offers enhanced control over security protocols and data protection measures, reducing risks associated with third-party access. Outsourced equipment may introduce vulnerabilities due to shared infrastructure and reliance on external providers' cybersecurity standards. Ensuring compliance with industry regulations like GDPR and HIPAA is critical when managing data on any equipment, but in-house setups allow for more direct oversight and rapid incident response.

Impact on Operational Efficiency

In-house equipment allows for immediate maintenance and customization, leading to faster response times and reduced downtime in operations. Outsourced equipment often provides access to the latest technology without the capital expense, but may introduce delays due to reliance on third-party service schedules. Balancing in-house control with outsourced innovation is crucial for optimizing operational efficiency.

Long-term Investment vs Short-term Expense

In-house equipment represents a long-term investment by providing greater control, consistent availability, and potential cost savings over time through asset depreciation and reduced rental fees. Outsourced equipment, classified as a short-term expense, offers flexibility and lower upfront costs but may incur higher cumulative expenses and less control over maintenance and availability. Businesses must weigh the capital expenditure and operational benefits of in-house assets against the variable costs and scalability of outsourcing to optimize equipment strategy.

Choosing the Right Equipment Strategy for Your Business

Selecting between in-house equipment and outsourced equipment hinges on factors like cost-efficiency, operational control, and maintenance capabilities. In-house equipment demands higher upfront investment but offers greater control and customization suited for long-term use, while outsourced equipment reduces capital expenditure and transfers maintenance responsibilities, benefiting businesses with fluctuating demand. Analyzing equipment lifecycle costs, scalability needs, and core business focus ensures a strategic alignment with company goals and resource optimization.

In-house equipment vs outsourced equipment Infographic

productdif.com

productdif.com