Stepper motors offer precise position control and simplicity, making them ideal for applications requiring repetitive, incremental movements without complex feedback systems. Servo motors provide higher torque, speed, and efficiency with closed-loop control, suited for dynamic and high-performance tasks demanding accuracy and responsiveness. Choosing between stepper and servo motors depends on factors such as required precision, load, speed, and system complexity.

Table of Comparison

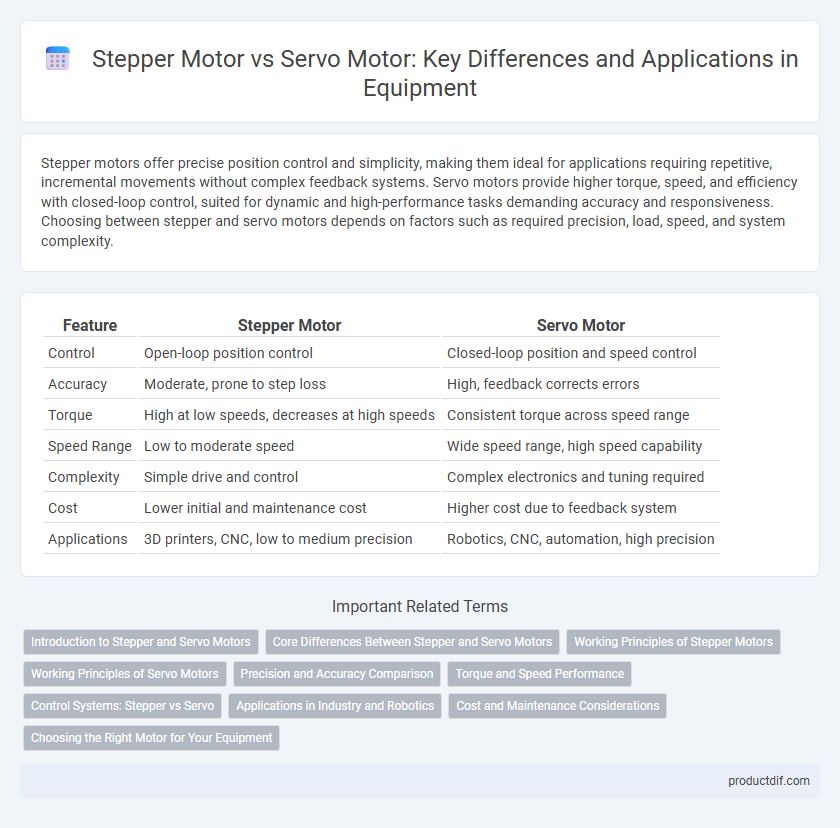

| Feature | Stepper Motor | Servo Motor |

|---|---|---|

| Control | Open-loop position control | Closed-loop position and speed control |

| Accuracy | Moderate, prone to step loss | High, feedback corrects errors |

| Torque | High at low speeds, decreases at high speeds | Consistent torque across speed range |

| Speed Range | Low to moderate speed | Wide speed range, high speed capability |

| Complexity | Simple drive and control | Complex electronics and tuning required |

| Cost | Lower initial and maintenance cost | Higher cost due to feedback system |

| Applications | 3D printers, CNC, low to medium precision | Robotics, CNC, automation, high precision |

Introduction to Stepper and Servo Motors

Stepper motors provide precise position control through fixed step increments, making them ideal for applications requiring accurate, repeatable motion. Servo motors deliver high torque and speed with continuous feedback, ensuring smooth and dynamic control in complex systems. Both motors serve crucial roles in automation, robotics, and CNC machinery, each optimized for specific performance requirements.

Core Differences Between Stepper and Servo Motors

Stepper motors provide precise open-loop control with fixed step angles, making them ideal for applications requiring simple, cost-effective positioning without feedback. Servo motors deliver high torque and speed with closed-loop feedback, enabling accurate and dynamic motion control in complex systems. Core differences include control method, torque output, speed range, and system complexity, which influence their suitability across robotics, CNC machines, and automation equipment.

Working Principles of Stepper Motors

Stepper motors operate by dividing a full rotation into equal steps, typically controlled by pulses sent to its coils. Each pulse causes the motor shaft to move a fixed angle increment, enabling precise positioning without feedback systems. The multiple electromagnetic coils are energized in a sequence, creating a rotating magnetic field that advances the rotor step by step.

Working Principles of Servo Motors

Servo motors operate using a closed-loop control system that continuously monitors and adjusts the motor's position, speed, and torque with the help of feedback devices like encoders or resolvers. They receive commands from a controller, which compares the actual position to the desired position and adjusts the current to the motor winding accordingly to achieve precise motion control. This feedback-driven operation enables servo motors to deliver high accuracy, smooth rotation, and dynamic response in automation and robotics applications.

Precision and Accuracy Comparison

Stepper motors deliver consistent incremental movements with high repeatability, making them ideal for applications requiring moderate precision. Servo motors excel in accuracy due to closed-loop feedback systems, allowing precise position control and minimal error in dynamic environments. For tasks demanding exact positioning and rapid response, servo motors outperform stepper motors in both precision and accuracy metrics.

Torque and Speed Performance

Stepper motors deliver precise torque at low to moderate speeds, making them ideal for applications requiring accurate positioning but limited speed. Servo motors provide higher torque across a wider speed range, enhancing performance in dynamic systems that demand rapid acceleration and sustained high-speed operation. Torque ripple in stepper motors often results in vibration at higher speeds, whereas servo motors maintain smoother motion due to feedback control.

Control Systems: Stepper vs Servo

Stepper motors offer precise open-loop control with simple pulse signals, making them ideal for applications requiring fixed, repeatable steps without feedback. Servo motors utilize closed-loop control systems with feedback encoders, enabling dynamic adjustment of position, speed, and torque for high-performance and complex motion tasks. Servo control systems provide superior accuracy and efficiency in applications demanding rapid acceleration, smooth motion, and load variation handling.

Applications in Industry and Robotics

Stepper motors are ideal for applications requiring precise, incremental movements such as 3D printers, CNC machines, and robotic arms in assembly lines, where open-loop control is sufficient. Servo motors are preferred in robotics and industrial automation for tasks demanding high torque, speed, and precise positioning under varying loads, including robotic welding, conveyor systems, and automated guided vehicles (AGVs). The choice between stepper and servo motors depends on factors like load requirements, speed variation, and control complexity in manufacturing and robotic applications.

Cost and Maintenance Considerations

Stepper motors typically have lower upfront costs and simpler maintenance due to their simpler construction and fewer components. Servo motors, while more expensive initially, offer higher precision and durability, often resulting in reduced long-term maintenance expenses. Cost-effectiveness depends on application requirements, with stepper motors favored for budget-conscious projects and servo motors preferred in performance-critical environments.

Choosing the Right Motor for Your Equipment

Choosing the right motor for your equipment involves evaluating torque requirements, precision, and control complexity. Stepper motors excel in applications needing precise position control with moderate torque and simpler electronics, ideal for 3D printers and CNC machines. Servo motors offer higher torque, faster speeds, and closed-loop feedback, making them suitable for robotics, automated machinery, and dynamic motion control tasks.

Stepper motor vs servo motor Infographic

productdif.com

productdif.com