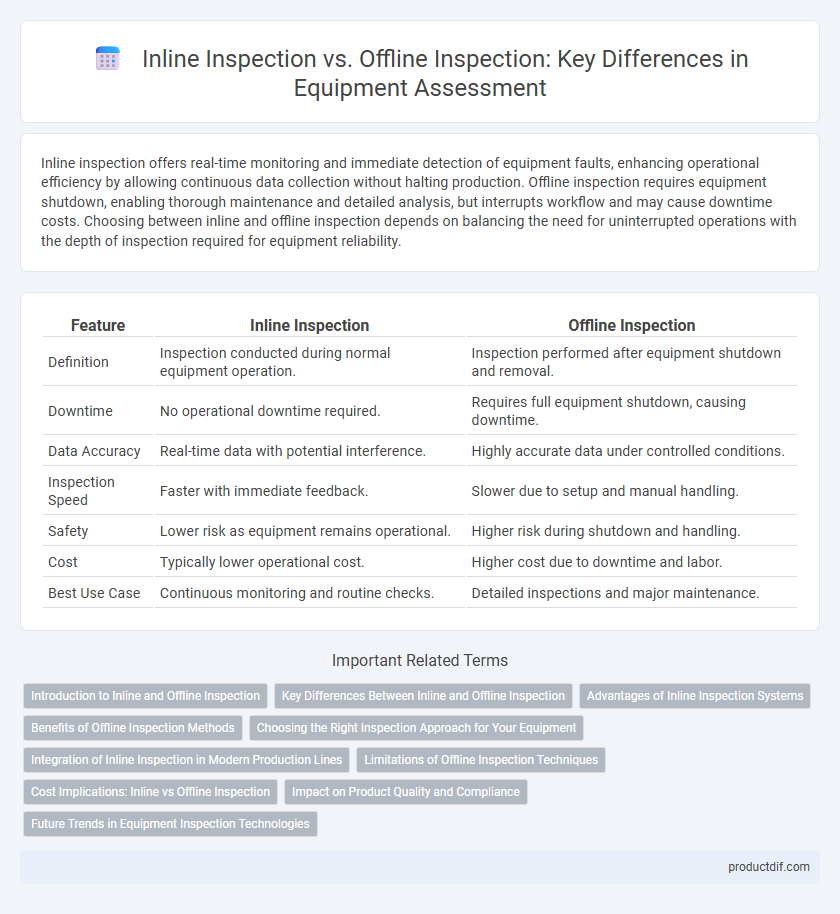

Inline inspection offers real-time monitoring and immediate detection of equipment faults, enhancing operational efficiency by allowing continuous data collection without halting production. Offline inspection requires equipment shutdown, enabling thorough maintenance and detailed analysis, but interrupts workflow and may cause downtime costs. Choosing between inline and offline inspection depends on balancing the need for uninterrupted operations with the depth of inspection required for equipment reliability.

Table of Comparison

| Feature | Inline Inspection | Offline Inspection |

|---|---|---|

| Definition | Inspection conducted during normal equipment operation. | Inspection performed after equipment shutdown and removal. |

| Downtime | No operational downtime required. | Requires full equipment shutdown, causing downtime. |

| Data Accuracy | Real-time data with potential interference. | Highly accurate data under controlled conditions. |

| Inspection Speed | Faster with immediate feedback. | Slower due to setup and manual handling. |

| Safety | Lower risk as equipment remains operational. | Higher risk during shutdown and handling. |

| Cost | Typically lower operational cost. | Higher cost due to downtime and labor. |

| Best Use Case | Continuous monitoring and routine checks. | Detailed inspections and major maintenance. |

Introduction to Inline and Offline Inspection

Inline inspection integrates real-time monitoring sensors directly within equipment or pipelines, enabling continuous data collection and immediate identification of defects or anomalies. Offline inspection involves periodic equipment shutdowns for detailed manual or automated examination using specialized tools, allowing thorough evaluation without process interruptions. Selecting the appropriate method depends on operational priorities, equipment type, and the criticality of early defect detection to ensure optimal maintenance and reliability.

Key Differences Between Inline and Offline Inspection

Inline inspection integrates sensors and monitoring devices directly into the production line, enabling real-time data collection and immediate defect detection for continuous process control. Offline inspection occurs separately from the production process, requiring product sampling and manual or automated testing in a controlled environment, which allows for more detailed analysis but introduces delays. Key differences include inspection speed, with inline providing faster feedback, and inspection flexibility, where offline methods enable more comprehensive testing options.

Advantages of Inline Inspection Systems

Inline inspection systems provide continuous, real-time monitoring of equipment, enabling early detection of defects and reducing downtime significantly. These systems enhance operational efficiency by minimizing manual intervention and allowing immediate corrective actions, which lowers maintenance costs. Advanced sensors and automated data analytics in inline inspections improve accuracy and reliability compared to traditional offline inspection methods.

Benefits of Offline Inspection Methods

Offline inspection methods provide the advantage of thorough, uncontrolled environmental analysis allowing for detailed equipment evaluation without disrupting operational processes. These techniques enable the use of specialized tools and advanced technologies that may not be compatible with inline systems, resulting in higher accuracy and comprehensive defect detection. Offline inspection also facilitates scheduled maintenance planning by offering precise data collection and in-depth condition assessment, ultimately enhancing equipment reliability and lifespan.

Choosing the Right Inspection Approach for Your Equipment

Inline inspection offers continuous, real-time monitoring of equipment condition, enabling early detection of wear and potential failures without interrupting operations. Offline inspection requires equipment shutdown, allowing for more detailed and thorough examination, essential for identifying issues not detectable during inline checks. Selecting the right inspection approach depends on factors such as equipment criticality, operational downtime costs, and the level of detail required for maintenance decisions.

Integration of Inline Inspection in Modern Production Lines

Inline inspection systems are seamlessly integrated into modern production lines using advanced sensors and real-time data analytics to monitor equipment health and product quality without halting operations. These systems enhance efficiency by enabling continuous defect detection, predictive maintenance, and immediate corrective actions, reducing downtime compared to traditional offline inspection methods. Industry 4.0 technologies such as IoT, machine learning, and automation further optimize inline inspection, driving higher accuracy and operational agility in manufacturing processes.

Limitations of Offline Inspection Techniques

Offline inspection techniques require equipment shutdowns, leading to significant operational downtime and production losses. These methods often lack the ability to detect internal defects with high accuracy, limiting the reliability of corrosion and crack assessments. Furthermore, offline inspections are constrained by accessibility issues, as certain pipeline sections may be difficult to dismantle or transport for detailed examination.

Cost Implications: Inline vs Offline Inspection

Inline inspection systems significantly reduce operational downtime by enabling real-time equipment monitoring, which minimizes labor and maintenance costs. Offline inspections often require equipment shutdowns, leading to higher direct and indirect expenses due to production halts and extended labor hours. Investing in inline inspection technologies typically results in lower total cost of ownership through predictive maintenance and enhanced asset utilization.

Impact on Product Quality and Compliance

Inline inspection integrates real-time monitoring within the production process, enabling immediate detection and correction of defects, which significantly enhances product quality and ensures adherence to compliance standards. Offline inspection, conducted separately from the production line, may lead to delays in identifying quality issues, increasing the risk of non-compliance and product recalls. Implementing inline inspection systems reduces waste, improves consistency, and supports continuous compliance with industry regulations.

Future Trends in Equipment Inspection Technologies

Future trends in equipment inspection technologies emphasize the integration of inline inspection systems equipped with advanced sensors and AI algorithms, enabling real-time defect detection and predictive maintenance. Offline inspection methods are evolving with enhanced automation, machine learning models, and augmented reality tools that increase accuracy and reduce downtime during equipment analysis. The convergence of digital twin technology and IoT platforms drives the shift towards smart inspection processes that optimize operational efficiency and asset reliability in industries such as manufacturing, oil and gas, and aerospace.

Inline inspection vs Offline inspection Infographic

productdif.com

productdif.com