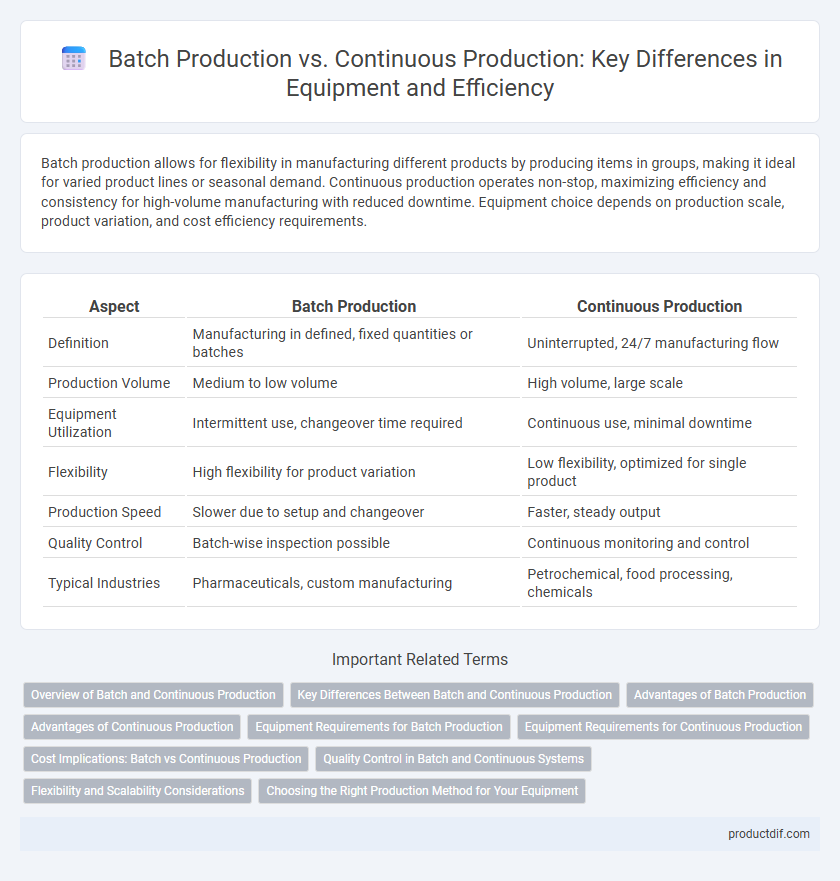

Batch production allows for flexibility in manufacturing different products by producing items in groups, making it ideal for varied product lines or seasonal demand. Continuous production operates non-stop, maximizing efficiency and consistency for high-volume manufacturing with reduced downtime. Equipment choice depends on production scale, product variation, and cost efficiency requirements.

Table of Comparison

| Aspect | Batch Production | Continuous Production |

|---|---|---|

| Definition | Manufacturing in defined, fixed quantities or batches | Uninterrupted, 24/7 manufacturing flow |

| Production Volume | Medium to low volume | High volume, large scale |

| Equipment Utilization | Intermittent use, changeover time required | Continuous use, minimal downtime |

| Flexibility | High flexibility for product variation | Low flexibility, optimized for single product |

| Production Speed | Slower due to setup and changeover | Faster, steady output |

| Quality Control | Batch-wise inspection possible | Continuous monitoring and control |

| Typical Industries | Pharmaceuticals, custom manufacturing | Petrochemical, food processing, chemicals |

Overview of Batch and Continuous Production

Batch production involves manufacturing products in specific, fixed quantities or lots, allowing flexibility in product variations and easier quality control. Continuous production operates on an uninterrupted flow, producing large volumes of standardized products with high efficiency and reduced per-unit costs. Equipment used in batch production often includes versatile machinery capable of handling various tasks, whereas continuous production relies on specialized, automated systems designed for constant operation.

Key Differences Between Batch and Continuous Production

Batch production involves manufacturing products in specified groups or quantities, allowing for flexibility and customization, while continuous production operates 24/7 with a constant flow, optimizing efficiency for high-volume output. Batch production requires frequent equipment changeovers, which can lead to downtime, whereas continuous production uses dedicated, automated machinery designed for uninterrupted operation. Key differences include production scale, flexibility, equipment usage, and suitability for various product types in equipment-intensive industries.

Advantages of Batch Production

Batch production offers flexibility by enabling manufacturers to produce customized product quantities that cater to specific market demands. It reduces the risk of overproduction and inventory costs by allowing for smaller, manageable production runs. This method also facilitates quality control and adjustments between batches, improving overall product consistency and efficiency.

Advantages of Continuous Production

Continuous production offers superior efficiency by minimizing downtime and enabling consistent output over long periods, which significantly reduces per-unit costs. It allows for better quality control with automated monitoring systems, ensuring uniform product standards and fewer defects. This method also supports high-volume manufacturing, making it ideal for industries like chemicals, pharmaceuticals, and food processing where large-scale, uninterrupted production is critical.

Equipment Requirements for Batch Production

Batch production requires versatile and flexible equipment capable of handling variable batch sizes and frequent changeovers to accommodate different products. Equipment must support efficient cleaning and maintenance procedures to minimize downtime between batches, ensuring product quality and preventing cross-contamination. Typically, batch production machinery includes modular components and adjustable settings to optimize production runs while maintaining cost-effectiveness.

Equipment Requirements for Continuous Production

Continuous production requires highly automated, durable equipment capable of operating 24/7 with minimal downtime to maintain product consistency. Equipment must support real-time monitoring and advanced control systems for precise process adjustments and quality assurance. Robust maintenance protocols and modular designs enable quick repairs and scalability to meet varying production demands.

Cost Implications: Batch vs Continuous Production

Batch production incurs higher per-unit costs due to frequent equipment changeovers, setup times, and downtime, which reduce overall operational efficiency. Continuous production benefits from economies of scale, maintaining consistent equipment operation that lowers unit costs by minimizing idle time and maximizing throughput. Investment in specialized continuous production equipment can have higher initial costs but leads to significant long-term savings and cost predictability in high-volume manufacturing.

Quality Control in Batch and Continuous Systems

Batch production allows for thorough quality control inspections after each batch is completed, enabling the identification and correction of defects before the next batch begins. Continuous production relies on real-time quality monitoring systems and automated sensors to maintain consistent product standards, minimizing downtime and reducing variability. Both methods require robust quality control protocols, but batch systems offer greater flexibility for testing, while continuous systems emphasize process stability and immediate feedback.

Flexibility and Scalability Considerations

Batch production offers greater flexibility by allowing manufacturers to switch between different products or adjust batch sizes to meet changing demand, making it ideal for smaller-scale or customized orders. Continuous production excels in scalability, enabling high-volume output with consistent quality and lower per-unit costs, which suits large-scale manufacturing with stable product lines. Equipment selection must balance the need for adaptability in batch processes with the efficiency and throughput advantages of continuous operations.

Choosing the Right Production Method for Your Equipment

Batch production offers flexibility for manufacturing varied products in limited quantities, making it ideal for equipment requiring customization or frequent design changes. Continuous production maximizes efficiency and consistency by operating non-stop, suited for high-volume equipment manufacturing with stable demand. Evaluating factors like production scale, equipment capability, cost-efficiency, and product complexity guides selecting the optimal production method.

Batch production vs Continuous production Infographic

productdif.com

productdif.com