Vacuum forming and thermoforming both shape plastic sheets using heat, but vacuum forming specifically involves pulling the heated sheet over a mold using vacuum pressure, resulting in detailed, lightweight parts. Thermoforming encompasses a broader range of techniques, including vacuum forming, pressure forming, and mechanical forming, allowing more versatility in part complexity and thickness. Choosing between the two depends on the desired product specifications, production volume, and material limitations.

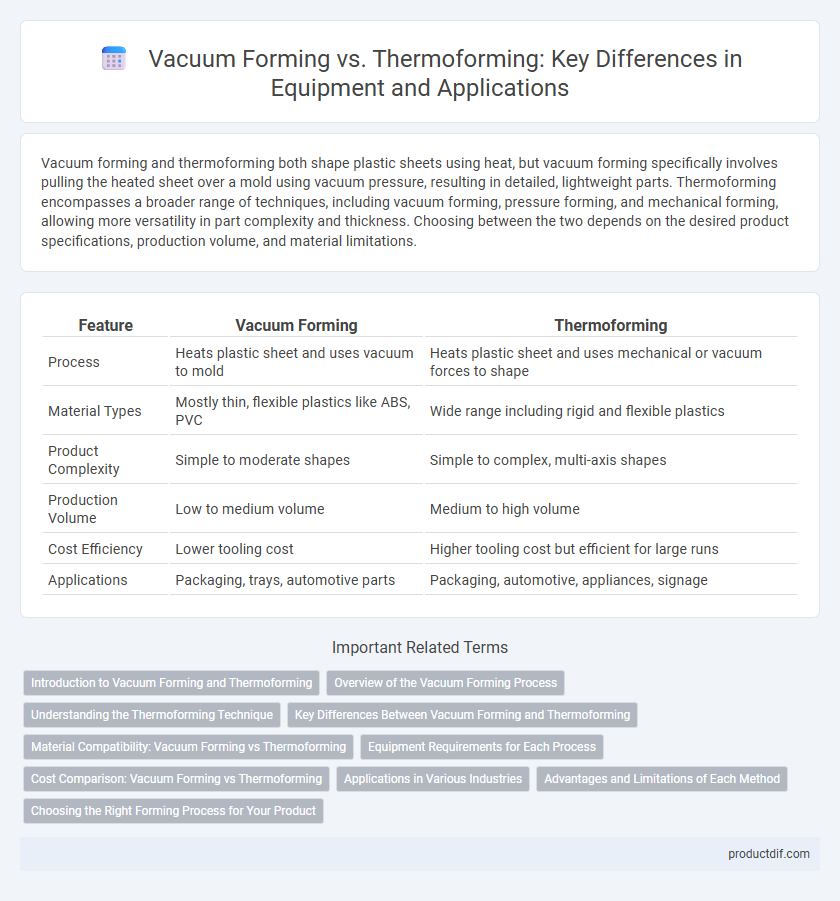

Table of Comparison

| Feature | Vacuum Forming | Thermoforming |

|---|---|---|

| Process | Heats plastic sheet and uses vacuum to mold | Heats plastic sheet and uses mechanical or vacuum forces to shape |

| Material Types | Mostly thin, flexible plastics like ABS, PVC | Wide range including rigid and flexible plastics |

| Product Complexity | Simple to moderate shapes | Simple to complex, multi-axis shapes |

| Production Volume | Low to medium volume | Medium to high volume |

| Cost Efficiency | Lower tooling cost | Higher tooling cost but efficient for large runs |

| Applications | Packaging, trays, automotive parts | Packaging, automotive, appliances, signage |

Introduction to Vacuum Forming and Thermoforming

Vacuum forming uses heated plastic sheets that are stretched over a mold while a vacuum removes air, shaping the material precisely. Thermoforming is a broader process that includes vacuum forming and other methods like pressure forming to mold heated plastic sheets. Both techniques are essential in manufacturing lightweight, custom plastic components efficiently.

Overview of the Vacuum Forming Process

Vacuum forming is a thermoforming technique that uses heat to soften a plastic sheet, which is then stretched over a mold while a vacuum removes the air between the sheet and the mold, creating a precise shape. This process is widely used for manufacturing packaging, automotive parts, and consumer products due to its cost-effectiveness and ability to produce detailed designs. Key equipment includes a heating element to soften the plastic, a vacuum system to pull the material against the mold, and a forming station to hold the mold securely.

Understanding the Thermoforming Technique

Thermoforming is a manufacturing process that heats a plastic sheet until pliable, then shapes it over a mold using vacuum, pressure, or mechanical means, making it ideal for producing detailed and complex parts. Unlike vacuum forming, which relies solely on vacuum pressure to shape the material, thermoforming can incorporate both vacuum and positive pressure to achieve higher precision and stronger parts. This versatility makes thermoforming suitable for applications in automotive, packaging, and medical device industries where both accuracy and material consistency are critical.

Key Differences Between Vacuum Forming and Thermoforming

Vacuum forming utilizes vacuum pressure to shape heated plastic sheets over a mold, primarily suited for shallow, simple designs, while thermoforming encompasses a broader range of methods including vacuum forming, pressure forming, and mechanical forming, capable of producing more complex and detailed products. Vacuum forming is generally more cost-effective for lower production volumes and simpler shapes, whereas thermoforming offers greater versatility with varying pressures and mold types, enabling higher precision and structural complexity. Key differences also lie in tooling costs, production speed, and material usage, with vacuum forming typically requiring less expensive molds and faster cycle times compared to other thermoforming techniques.

Material Compatibility: Vacuum Forming vs Thermoforming

Vacuum forming is highly compatible with thin-sheet thermoplastics such as ABS, polystyrene, and polyethylene, ideal for creating detailed shapes with consistent thickness. Thermoforming extends material compatibility to thicker gauges and more rigid plastics like PVC and acrylic, enabling the production of durable, structural components. Both processes offer versatile options but differ significantly in the range of materials they can efficiently shape, impacting the choice based on product requirements.

Equipment Requirements for Each Process

Vacuum forming requires a vacuum pump, a heated plastic sheet clamping frame, and a mold, emphasizing precise temperature control and vacuum pressure equipment to shape the material effectively. Thermoforming equipment involves a heating system to soften large plastic sheets and a forming station that can use vacuum, pressure, or mechanical force, demanding robust press machinery for complex part shapes. Both processes rely on accurate temperature regulation and mold design, but thermoforming equipment typically accommodates thicker materials and more intricate forming techniques.

Cost Comparison: Vacuum Forming vs Thermoforming

Vacuum forming typically incurs lower initial tooling costs compared to thermoforming, making it more cost-effective for small to medium production runs. Thermoforming, while involving higher upfront expenses due to complex molds and equipment, becomes more economical for large-scale manufacturing because of faster cycle times and material efficiency. Overall, vacuum forming suits budget-conscious projects with shorter production schedules, whereas thermoforming offers better long-term cost advantages in high-volume applications.

Applications in Various Industries

Vacuum forming is widely used in packaging, automotive, and medical industries due to its ability to create detailed molds and lightweight components. Thermoforming applies to food containers, trays, and signage because of its efficiency in shaping large plastic sheets with consistent thickness. Both processes support mass production in aerospace, consumer products, and electronics by enabling cost-effective, customizable plastic parts.

Advantages and Limitations of Each Method

Vacuum forming offers rapid production and cost-effective tooling, making it ideal for large, simple shapes, but it is limited by the thickness and complexity of the materials that can be formed. Thermoforming provides greater design flexibility and the ability to use thicker and multi-layered sheets, though it requires higher initial tooling costs and longer cycle times. Both methods serve distinct manufacturing needs, with vacuum forming favoring speed and economy, while thermoforming excels in customization and material variety.

Choosing the Right Forming Process for Your Product

Selecting the appropriate forming process depends on factors such as material type, production volume, and product complexity. Vacuum forming offers cost-effective solutions for larger parts with moderate detail, while thermoforming allows for more intricate shapes and tighter tolerances. Evaluating product requirements alongside equipment capabilities ensures optimal quality and efficiency in manufacturing.

Vacuum forming vs Thermoforming Infographic

productdif.com

productdif.com