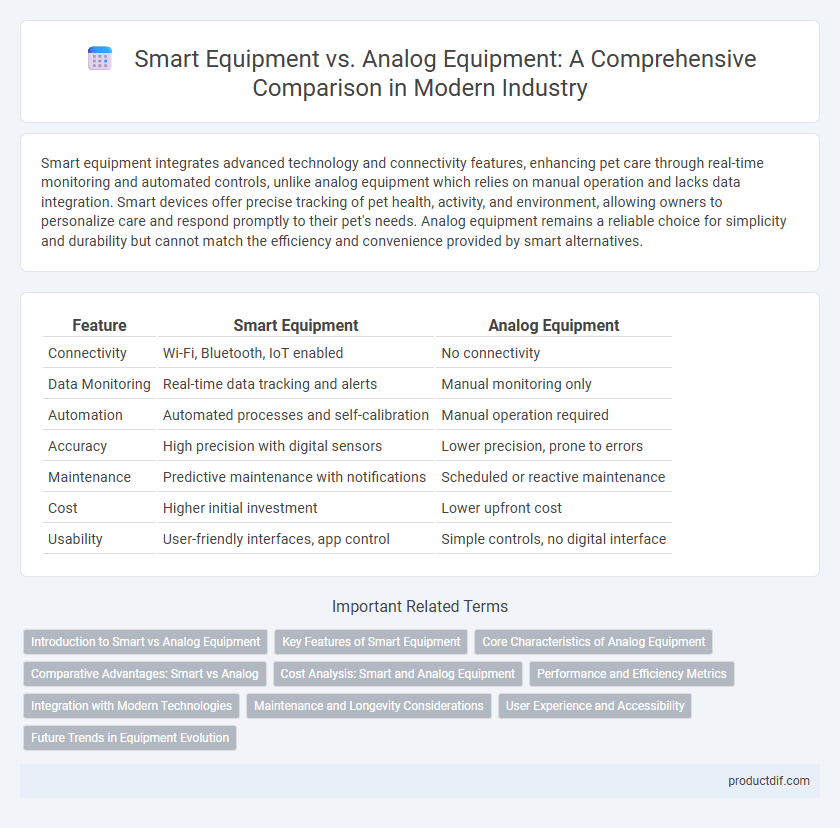

Smart equipment integrates advanced technology and connectivity features, enhancing pet care through real-time monitoring and automated controls, unlike analog equipment which relies on manual operation and lacks data integration. Smart devices offer precise tracking of pet health, activity, and environment, allowing owners to personalize care and respond promptly to their pet's needs. Analog equipment remains a reliable choice for simplicity and durability but cannot match the efficiency and convenience provided by smart alternatives.

Table of Comparison

| Feature | Smart Equipment | Analog Equipment |

|---|---|---|

| Connectivity | Wi-Fi, Bluetooth, IoT enabled | No connectivity |

| Data Monitoring | Real-time data tracking and alerts | Manual monitoring only |

| Automation | Automated processes and self-calibration | Manual operation required |

| Accuracy | High precision with digital sensors | Lower precision, prone to errors |

| Maintenance | Predictive maintenance with notifications | Scheduled or reactive maintenance |

| Cost | Higher initial investment | Lower upfront cost |

| Usability | User-friendly interfaces, app control | Simple controls, no digital interface |

Introduction to Smart vs Analog Equipment

Smart equipment integrates advanced sensors and connectivity features that enable real-time data monitoring, remote control, and predictive maintenance, enhancing operational efficiency. Analog equipment relies on traditional mechanical or electrical components without digital interfaces, limiting automation and data analytics capabilities. The transition from analog to smart equipment drives innovation by improving accuracy, reducing downtime, and enabling data-driven decision-making in industrial and commercial applications.

Key Features of Smart Equipment

Smart equipment integrates advanced sensors and IoT connectivity, enabling real-time data monitoring and remote control for optimized performance and predictive maintenance. Unlike analog equipment, smart devices offer enhanced automation, adaptive responses, and seamless integration with digital platforms, improving operational efficiency and reducing downtime. Enhanced data analytics and machine learning capabilities in smart equipment facilitate proactive decision-making and continuous improvements in industrial processes.

Core Characteristics of Analog Equipment

Analog equipment operates using continuous signals that vary in amplitude or frequency, enabling real-time data processing and natural signal representation. It is characterized by simplicity, durability, and direct interaction with physical phenomena without digital conversion. This equipment typically excels in environments requiring high reliability and straightforward maintenance due to its mechanical components and less complex circuitry.

Comparative Advantages: Smart vs Analog

Smart equipment offers real-time data monitoring, predictive maintenance, and enhanced operational efficiency compared to analog equipment, which relies on manual controls and lacks connectivity features. The integration of IoT technology in smart equipment enables seamless automation and remote management, reducing downtime and operational costs. Analog equipment, while often simpler and more affordable initially, requires more frequent manual intervention and is less adaptable to modern digital systems.

Cost Analysis: Smart and Analog Equipment

Smart equipment often involves higher upfront costs due to advanced sensors, connectivity features, and integrated software platforms, but it enables predictive maintenance and operational efficiency, reducing long-term expenses. Analog equipment typically has lower initial purchase prices but may incur increased maintenance costs and downtime due to manual monitoring and less precise control. Cost analysis should weigh total cost of ownership, factoring in installation, training, energy consumption, and potential productivity gains from smart equipment versus the straightforward and established costs of analog counterparts.

Performance and Efficiency Metrics

Smart equipment leverages advanced sensors and IoT connectivity to provide real-time performance data, enabling predictive maintenance and minimizing downtime. Analog equipment often relies on manual monitoring and fixed settings, resulting in less precise operation and higher energy consumption. Smart systems demonstrate up to 30% improvement in energy efficiency and a 20% increase in overall equipment effectiveness (OEE) compared to traditional analog counterparts.

Integration with Modern Technologies

Smart equipment offers seamless integration with modern technologies through IoT connectivity, real-time data analytics, and cloud-based control systems, enhancing operational efficiency and predictive maintenance. Analog equipment lacks these capabilities, resulting in limited interoperability and slower response times in automated environments. The ability of smart equipment to interface with AI-driven software and remote monitoring platforms sets it apart in industrial automation and smart manufacturing.

Maintenance and Longevity Considerations

Smart equipment features advanced sensors and predictive maintenance capabilities that significantly reduce downtime and extend operational lifespan compared to analog equipment. Analog equipment typically requires more frequent manual inspections and routine maintenance, increasing labor costs and the risk of unexpected failures. Investing in smart equipment enhances overall reliability and optimizes maintenance schedules, promoting longer service life and improved asset management.

User Experience and Accessibility

Smart equipment enhances user experience by integrating intuitive interfaces, real-time feedback, and adaptive controls, enabling personalized and efficient operation. Analog equipment offers simplicity and tactile familiarity, but lacks advanced accessibility features crucial for users with disabilities. Incorporating connectivity and automation in smart tools significantly improves accessibility by supporting voice commands, remote monitoring, and customizable settings.

Future Trends in Equipment Evolution

Smart equipment integrates IoT connectivity, AI-driven analytics, and real-time data monitoring, enabling predictive maintenance and enhanced operational efficiency. Analog equipment, limited by manual controls and isolated functions, faces obsolescence as industries prioritize automation and digital transformation. Emerging trends highlight a shift towards hybrid systems that combine the reliability of analog with the adaptability of smart technology, accelerating the evolution of industrial and consumer machinery.

Smart equipment vs analog equipment Infographic

productdif.com

productdif.com