CNC machining offers superior precision and repeatability compared to manual machining, allowing for complex designs and tighter tolerances. Manual machining provides greater flexibility and is often preferred for custom or low-volume production where setup costs of CNC are not justified. The choice between CNC and manual machining depends on factors like production volume, complexity, and cost efficiency.

Table of Comparison

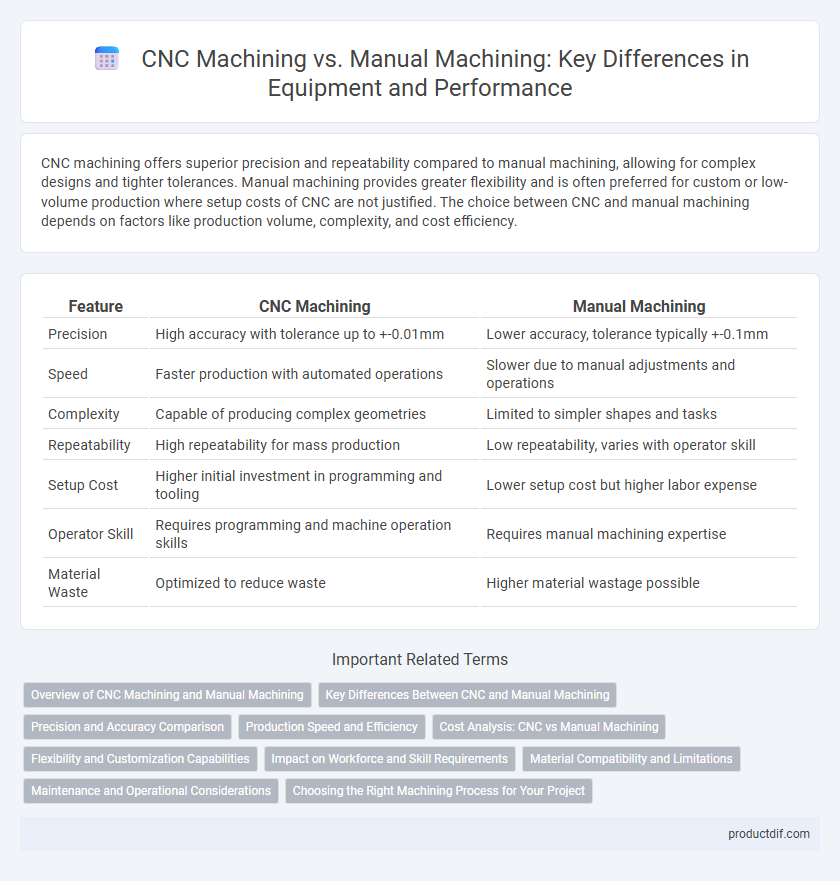

| Feature | CNC Machining | Manual Machining |

|---|---|---|

| Precision | High accuracy with tolerance up to +-0.01mm | Lower accuracy, tolerance typically +-0.1mm |

| Speed | Faster production with automated operations | Slower due to manual adjustments and operations |

| Complexity | Capable of producing complex geometries | Limited to simpler shapes and tasks |

| Repeatability | High repeatability for mass production | Low repeatability, varies with operator skill |

| Setup Cost | Higher initial investment in programming and tooling | Lower setup cost but higher labor expense |

| Operator Skill | Requires programming and machine operation skills | Requires manual machining expertise |

| Material Waste | Optimized to reduce waste | Higher material wastage possible |

Overview of CNC Machining and Manual Machining

CNC machining utilizes computer-controlled tools to produce precise and complex parts with high repeatability, significantly reducing human error and production time. Manual machining relies on skilled operators manipulating machines like lathes and mills, offering greater flexibility for custom or small-scale tasks but often resulting in slower production rates and less consistency. Both methods serve vital roles in manufacturing, with CNC machining excelling in volume and complexity, while manual machining is preferred for intricate adjustments and craftsmanship.

Key Differences Between CNC and Manual Machining

CNC machining offers higher precision and repeatability by using computer-controlled tools, while manual machining relies on operator skill, resulting in greater variability. CNC machines enable faster production speeds and complex geometries compared to the slower, simpler operations feasible with manual machining. Maintenance and setup of CNC equipment demand specialized expertise, whereas manual machining requires more hands-on adjustments and continuous operator supervision.

Precision and Accuracy Comparison

CNC machining offers superior precision and accuracy compared to manual machining due to computer-controlled movements that ensure consistent, repeatable results within micrometer tolerances. Manual machining relies heavily on operator skill, often leading to greater variability and less exact dimensions, especially in complex or high-volume production. The integration of CNC systems significantly reduces human error, enabling tighter tolerances and higher-quality finished parts in precision manufacturing.

Production Speed and Efficiency

CNC machining offers significantly higher production speed compared to manual machining due to its automated precision and ability to operate continuously without fatigue. Efficiency is enhanced in CNC processes through minimized human error, consistent repeatability, and optimized tool paths, reducing material waste and downtime. Manual machining, while flexible for custom or low-volume tasks, cannot match the rapid throughput and streamlined workflow achieved by CNC systems in large-scale manufacturing.

Cost Analysis: CNC vs Manual Machining

CNC machining offers higher upfront equipment investment but reduces labor costs through automation, increasing long-term cost efficiency for complex and high-volume production. Manual machining incurs lower initial equipment expenses but requires skilled operators, resulting in higher labor costs and longer production times that impact overall cost-effectiveness. Cost analysis reveals CNC machining is more economical for large-scale manufacturing, while manual machining may be suitable for low-volume or custom jobs with limited budgets.

Flexibility and Customization Capabilities

CNC machining offers superior flexibility and customization capabilities by allowing precise control over complex geometries and rapid adjustments through computer programming. Manual machining relies heavily on operator skill and is limited in producing intricate designs or quickly modifying specifications. This makes CNC machining ideal for high-precision, customizable production runs and prototypes.

Impact on Workforce and Skill Requirements

CNC machining demands a workforce skilled in programming, computer-aided design (CAD), and operating automated machinery, reducing the need for manual dexterity but increasing technical expertise requirements. Manual machining relies heavily on hands-on skills and experience, requiring operators to possess in-depth knowledge of tool handling, precision measurement, and manual adjustments. The shift towards CNC machining transforms labor roles by prioritizing digital proficiency and continuous training to manage sophisticated equipment effectively.

Material Compatibility and Limitations

CNC machining excels in processing a wide range of materials, including hard metals like titanium and hardened steel, due to its precision and automated control, enabling complex geometries with minimal human error. Manual machining is often limited by operator skill and physical constraints, making it less suitable for brittle or extremely hard materials that require consistent, high-speed cutting. Materials prone to deformation or requiring intricate details benefit significantly from CNC machining's repeatability and advanced toolpath capabilities.

Maintenance and Operational Considerations

CNC machining requires regular software updates, precise calibration, and specialized technical maintenance to ensure optimal performance and minimize downtime. Manual machining demands consistent physical upkeep of mechanical components such as bearings, lead screws, and lubrication systems, often relying on operator expertise for troubleshooting. Operationally, CNC machines offer higher efficiency and repeatability, while manual machining allows greater flexibility for custom or one-off tasks but involves more hands-on adjustment and oversight.

Choosing the Right Machining Process for Your Project

CNC machining offers unparalleled precision and repeatability for complex parts, making it ideal for high-volume or intricate projects requiring tight tolerances. Manual machining provides better flexibility for low-volume production, custom adjustments, and simpler designs where setup costs and automation are less critical. Evaluating factors such as project complexity, production volume, cost constraints, and desired accuracy helps determine the optimal machining process.

CNC machining vs manual machining Infographic

productdif.com

productdif.com