Laser cutters offer precise, high-speed cutting suitable for thin materials like acrylic and wood, ideal for detailed designs with minimal waste. Waterjet cutters excel in cutting thicker and harder materials such as metal and stone without heat distortion, preserving material integrity. Selecting between laser and waterjet cutters depends on material type, thickness, and desired edge quality.

Table of Comparison

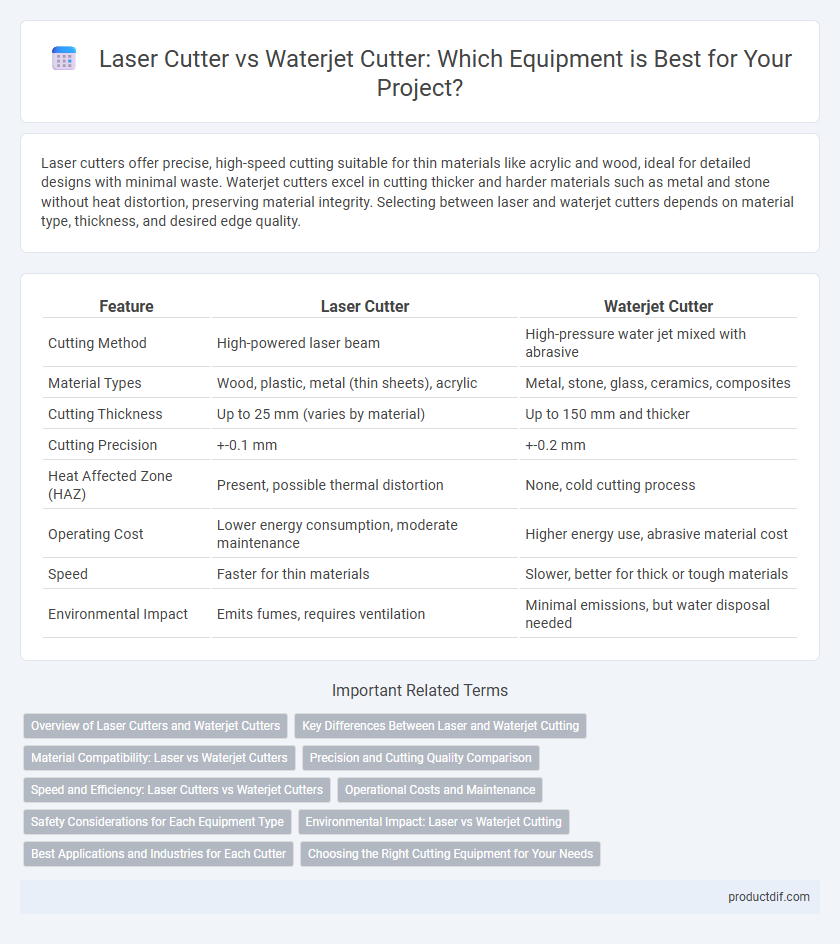

| Feature | Laser Cutter | Waterjet Cutter |

|---|---|---|

| Cutting Method | High-powered laser beam | High-pressure water jet mixed with abrasive |

| Material Types | Wood, plastic, metal (thin sheets), acrylic | Metal, stone, glass, ceramics, composites |

| Cutting Thickness | Up to 25 mm (varies by material) | Up to 150 mm and thicker |

| Cutting Precision | +-0.1 mm | +-0.2 mm |

| Heat Affected Zone (HAZ) | Present, possible thermal distortion | None, cold cutting process |

| Operating Cost | Lower energy consumption, moderate maintenance | Higher energy use, abrasive material cost |

| Speed | Faster for thin materials | Slower, better for thick or tough materials |

| Environmental Impact | Emits fumes, requires ventilation | Minimal emissions, but water disposal needed |

Overview of Laser Cutters and Waterjet Cutters

Laser cutters use focused high-powered laser beams to precisely cut or engrave materials such as metal, wood, acrylic, and plastic with minimal kerf and smooth edges. Waterjet cutters employ a high-pressure stream of water mixed with abrasive particles to cut through tougher materials including metal, stone, and ceramics without heat distortion or structural changes. Both technologies provide precise fabrication options, with laser cutters excelling in speed and detail, while waterjets handle thicker and heat-sensitive materials efficiently.

Key Differences Between Laser and Waterjet Cutting

Laser cutters use focused beams of light to precisely melt or vaporize materials, achieving high accuracy and fine detail on metals, plastics, and wood. Waterjet cutters employ high-pressure streams of water mixed with abrasive particles, enabling them to cut through thicker, heat-sensitive materials like stone, ceramics, and composites without thermal distortion. Laser cutting generally offers faster processing speeds, while waterjet cutting excels in versatility and material compatibility due to its cold cutting process.

Material Compatibility: Laser vs Waterjet Cutters

Laser cutters excel at cutting thin materials such as acrylic, wood, and certain plastics with high precision, typically handling thicknesses up to 20 mm. Waterjet cutters offer superior versatility by cutting a wide range of materials including metals, stone, glass, and composites, with the ability to cut materials thicker than 100 mm without thermal distortion. Material compatibility differences influence the choice between laser and waterjet cutters based on factors like thickness, hardness, thermal sensitivity, and desired edge quality.

Precision and Cutting Quality Comparison

Laser cutters deliver exceptional precision with cutting tolerances often within +-0.1 mm, producing clean, sharp edges ideal for intricate designs on metals, plastics, and wood. Waterjet cutters, while slightly less precise with tolerances around +-0.2 mm, excel in cutting thicker materials without heat-affected zones, preserving material integrity and avoiding warping. Both technologies offer superior cutting quality, but laser cutters are preferred for detailed, fine cuts, whereas waterjets are optimal for diverse material thicknesses and compositions.

Speed and Efficiency: Laser Cutters vs Waterjet Cutters

Laser cutters excel in speed, capable of slicing through thin to medium-thickness materials rapidly with precision, enhancing production efficiency for detailed tasks. Waterjet cutters, while slower due to the mechanical nature of abrasive jetting, offer superior efficiency in handling thicker, heat-sensitive materials without thermal distortion. Selecting between laser and waterjet cutters depends on balancing the need for rapid processing and material compatibility to optimize manufacturing workflows.

Operational Costs and Maintenance

Laser cutters generally have lower operational costs due to reduced consumable expenses and faster cutting speeds, while waterjet cutters incur higher costs from abrasive materials and increased water usage. Maintenance for laser cutters primarily involves regular optics cleaning and laser source replacement, whereas waterjet cutters require frequent pump maintenance and nozzle replacement due to abrasive wear. Selecting between the two depends on balancing lower ongoing operational costs of laser systems against the more intensive maintenance demands of waterjet equipment.

Safety Considerations for Each Equipment Type

Laser cutters require strict ventilation systems to manage hazardous fumes and intense light exposure, necessitating protective eyewear and fire-resistant enclosures to prevent burns and eye damage. Waterjet cutters, while eliminating airborne contaminants, pose risks from high-pressure water jets and abrasive materials, requiring robust shielding and personal protective equipment to avoid lacerations and injection injuries. Both equipment types demand comprehensive training and adherence to safety protocols to minimize operational hazards and ensure worker safety.

Environmental Impact: Laser vs Waterjet Cutting

Laser cutters generally consume less water and produce minimal waste compared to waterjet cutters, which use high-pressure water mixed with abrasive materials that can generate substantial wastewater. The energy consumption of laser cutting depends on the machine's power settings, often making it more energy-efficient for thin materials, while waterjet cutting can require more energy due to the high-pressure pump system. Laser cutting emits fewer airborne particulates, whereas waterjet cutting risks contaminating water sources if wastewater is not properly treated.

Best Applications and Industries for Each Cutter

Laser cutters excel in precision cutting of metals, plastics, and wood, making them ideal for industries such as electronics, automotive, and signage manufacturing. Waterjet cutters are preferred for cutting thick materials, including stone, glass, and composite metals, serving sectors like aerospace, construction, and heavy machinery. Each cutter's unique capabilities optimize performance, with laser cutting favored for detailed designs and waterjet cutting suited for robust, heat-sensitive materials.

Choosing the Right Cutting Equipment for Your Needs

Selecting between a laser cutter and a waterjet cutter depends on material type, thickness, and desired precision; laser cutters excel in cutting thin metals, plastics, and wood with high accuracy, while waterjet cutters handle thicker, tougher materials like stone and metal without thermal distortion. Laser cutters offer faster speeds and cleaner edges for detailed designs, whereas waterjet cutters provide versatility by cutting virtually any material without heat-affected zones. Evaluating factors such as production volume, material compatibility, edge finish, and budget ensures optimal equipment choice tailored to specific manufacturing or prototyping needs.

Laser cutter vs Waterjet cutter Infographic

productdif.com

productdif.com