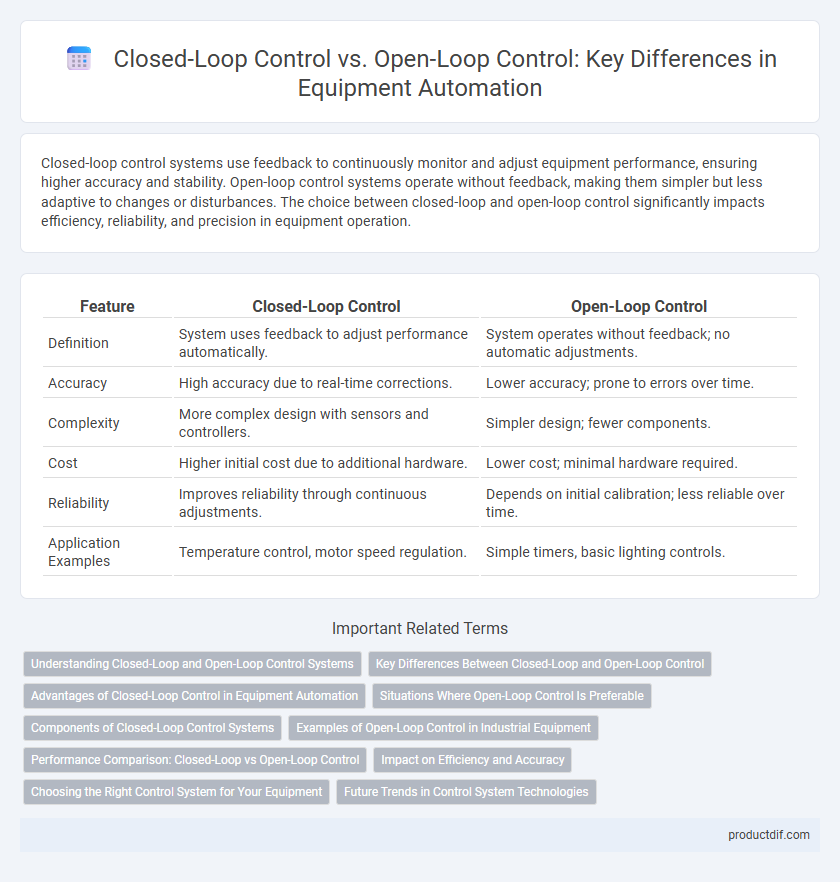

Closed-loop control systems use feedback to continuously monitor and adjust equipment performance, ensuring higher accuracy and stability. Open-loop control systems operate without feedback, making them simpler but less adaptive to changes or disturbances. The choice between closed-loop and open-loop control significantly impacts efficiency, reliability, and precision in equipment operation.

Table of Comparison

| Feature | Closed-Loop Control | Open-Loop Control |

|---|---|---|

| Definition | System uses feedback to adjust performance automatically. | System operates without feedback; no automatic adjustments. |

| Accuracy | High accuracy due to real-time corrections. | Lower accuracy; prone to errors over time. |

| Complexity | More complex design with sensors and controllers. | Simpler design; fewer components. |

| Cost | Higher initial cost due to additional hardware. | Lower cost; minimal hardware required. |

| Reliability | Improves reliability through continuous adjustments. | Depends on initial calibration; less reliable over time. |

| Application Examples | Temperature control, motor speed regulation. | Simple timers, basic lighting controls. |

Understanding Closed-Loop and Open-Loop Control Systems

Closed-loop control systems continuously monitor output variables through sensors and adjust inputs to maintain desired performance, ensuring higher accuracy and adaptability in dynamic environments. Open-loop control systems operate without feedback, relying on predetermined inputs, which can lead to errors if disturbances affect the process. Understanding the differences in response mechanisms and error correction is crucial for optimizing equipment performance and reliability in industrial applications.

Key Differences Between Closed-Loop and Open-Loop Control

Closed-loop control systems utilize feedback sensors to continuously monitor output and adjust inputs, ensuring precise and adaptive performance. Open-loop control systems operate without feedback, relying solely on predefined inputs, which can lead to inaccuracies in dynamic environments. Key differences include closed-loop's ability to correct errors in real time and maintain stability, while open-loop systems offer simpler design and lower cost but lack error correction.

Advantages of Closed-Loop Control in Equipment Automation

Closed-loop control in equipment automation offers precise regulation by continuously monitoring output and adjusting inputs, resulting in enhanced accuracy and reduced errors. This feedback mechanism improves system stability and compensates for disturbances, leading to consistent performance under varying conditions. Moreover, closed-loop control increases operational efficiency by minimizing energy consumption and wear on components through real-time adjustments.

Situations Where Open-Loop Control Is Preferable

Open-loop control systems are preferable in situations where system dynamics are well-known and disturbances are minimal, such as in simple conveyor belt operations or timed irrigation systems. They offer cost-effective and straightforward implementation without the need for feedback sensors, reducing complexity and maintenance requirements. In environments with predictable, repetitive tasks and stable conditions, open-loop control ensures efficient performance without the overhead of continuous monitoring.

Components of Closed-Loop Control Systems

Closed-loop control systems consist of essential components such as sensors, controllers, actuators, and feedback mechanisms that continuously monitor and adjust system performance. Sensors detect real-time output data, which the controller compares against desired setpoints to generate corrective signals for the actuators. Feedback loops enable dynamic adjustments, ensuring precision and stability in equipment operation under varying conditions.

Examples of Open-Loop Control in Industrial Equipment

Open-loop control systems in industrial equipment include applications like conveyor belts operating at fixed speeds regardless of load changes and irrigation systems that run water distribution on preset timers without moisture feedback. These systems rely on predetermined inputs without sensor feedback, making them simple but less adaptive to dynamic conditions. Common examples also include basic HVAC fans set to constant speeds and simple motor controllers that do not adjust based on output performance.

Performance Comparison: Closed-Loop vs Open-Loop Control

Closed-loop control systems offer superior performance over open-loop control by continuously monitoring output and adjusting inputs to reduce errors, resulting in higher accuracy and stability. Open-loop systems lack feedback mechanisms, making them prone to drift and disturbances, which can lead to inconsistent performance in precision equipment. In industrial automation, closed-loop control enhances process reliability and efficiency, crucial for applications requiring tight regulation and minimal deviation.

Impact on Efficiency and Accuracy

Closed-loop control systems significantly enhance equipment efficiency and accuracy by continuously monitoring output and adjusting inputs to maintain desired performance, reducing errors and waste. Open-loop control lacks feedback mechanisms, often resulting in less precise operations and increased resource consumption due to its inability to correct deviations in real-time. Implementing closed-loop control in industrial machinery leads to optimized process control, improved product quality, and lower operational costs.

Choosing the Right Control System for Your Equipment

Selecting the appropriate control system for your equipment hinges on the need for accuracy and responsiveness; closed-loop control systems utilize feedback to adjust outputs dynamically, ensuring precision in varying conditions. Open-loop control systems operate without feedback, making them simpler and cost-effective for processes with consistent inputs and predictable outcomes. Evaluating factors such as system complexity, environmental changes, and performance requirements will guide the decision between these two control strategies.

Future Trends in Control System Technologies

Future trends in control system technologies emphasize the integration of artificial intelligence and machine learning to enhance closed-loop control accuracy and adaptability in equipment operations. Advanced sensors and IoT connectivity enable real-time data feedback, optimizing closed-loop systems for predictive maintenance and energy efficiency. Emerging open-loop systems leverage automation and cloud-based platforms to streamline simpler processes while reducing implementation costs in industrial equipment.

Closed-Loop Control vs Open-Loop Control Infographic

productdif.com

productdif.com