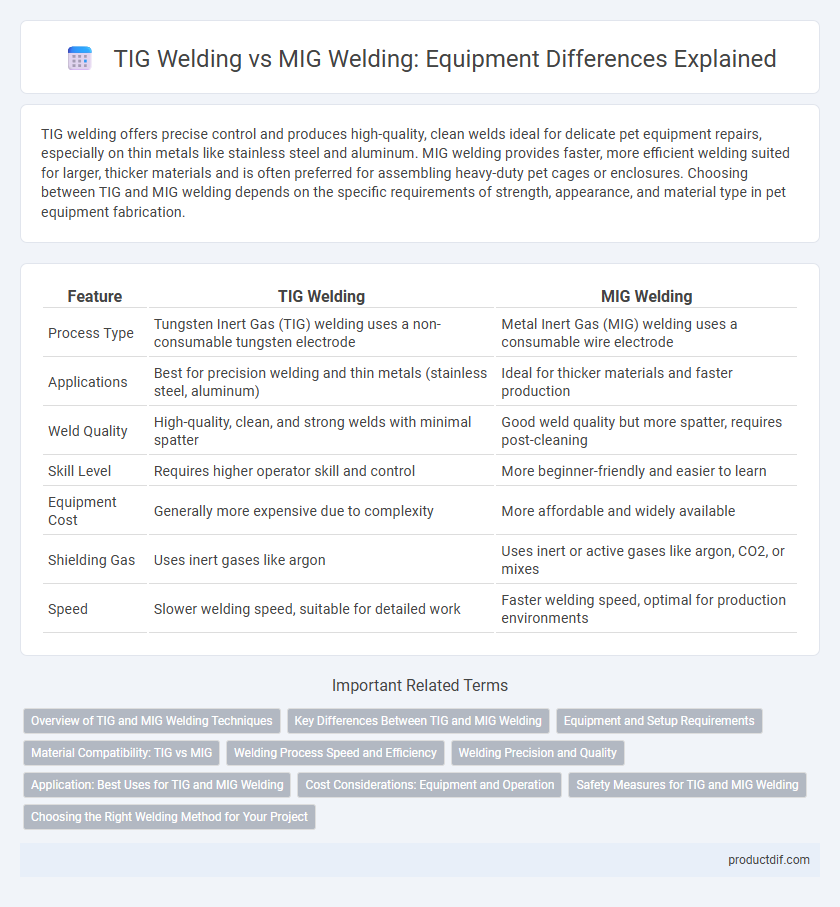

TIG welding offers precise control and produces high-quality, clean welds ideal for delicate pet equipment repairs, especially on thin metals like stainless steel and aluminum. MIG welding provides faster, more efficient welding suited for larger, thicker materials and is often preferred for assembling heavy-duty pet cages or enclosures. Choosing between TIG and MIG welding depends on the specific requirements of strength, appearance, and material type in pet equipment fabrication.

Table of Comparison

| Feature | TIG Welding | MIG Welding |

|---|---|---|

| Process Type | Tungsten Inert Gas (TIG) welding uses a non-consumable tungsten electrode | Metal Inert Gas (MIG) welding uses a consumable wire electrode |

| Applications | Best for precision welding and thin metals (stainless steel, aluminum) | Ideal for thicker materials and faster production |

| Weld Quality | High-quality, clean, and strong welds with minimal spatter | Good weld quality but more spatter, requires post-cleaning |

| Skill Level | Requires higher operator skill and control | More beginner-friendly and easier to learn |

| Equipment Cost | Generally more expensive due to complexity | More affordable and widely available |

| Shielding Gas | Uses inert gases like argon | Uses inert or active gases like argon, CO2, or mixes |

| Speed | Slower welding speed, suitable for detailed work | Faster welding speed, optimal for production environments |

Overview of TIG and MIG Welding Techniques

TIG welding uses a non-consumable tungsten electrode to create precise, high-quality welds ideal for thin metals and intricate joints, offering superior control and minimal spatter. MIG welding employs a consumable wire electrode fed through a welding gun, enabling faster weld speeds and easier handling, especially suited for thicker materials and production work. Both techniques require specific equipment configurations, with TIG demanding a shielding gas like argon for oxidation prevention and MIG commonly using a mix of argon and CO2 for enhanced weld stability.

Key Differences Between TIG and MIG Welding

TIG welding uses a non-consumable tungsten electrode and argon gas to produce precise, high-quality welds ideal for thin materials and intricate joints, while MIG welding employs a consumable wire electrode with a shielding gas, providing faster welding speeds suited for thicker materials and larger projects. TIG welding offers superior control and cleaner welds with minimal spatter, whereas MIG welding is more user-friendly and efficient for high-volume production. The choice between TIG and MIG depends on material type, weld quality requirements, and application speed.

Equipment and Setup Requirements

TIG welding equipment consists of a tungsten electrode, a high-frequency start generator, and a shielding gas supply, requiring precise control and setup for optimal performance. MIG welding uses a continuously fed wire electrode and a simpler power supply, which makes the setup faster and more user-friendly, especially for beginners. The TIG process demands more specialized equipment and skilled operation, while MIG welding equipment is generally more versatile and suitable for higher production rates.

Material Compatibility: TIG vs MIG

TIG welding excels in precise control and is ideal for welding thin or exotic metals such as stainless steel, aluminum, and copper alloys, ensuring strong, clean welds with minimal distortion. MIG welding is better suited for thicker materials like mild steel and is favored for its speed and ease of use in industrial applications, though it may produce more spatter and less precise welds. Material compatibility depends on factors such as metal type, thickness, and desired weld quality, with TIG preferred for precision and MIG for productivity.

Welding Process Speed and Efficiency

TIG welding offers precise control and produces high-quality welds but is generally slower due to the manual feeding of filler material, making it less efficient for large-scale production. MIG welding provides faster welding speeds with continuous wire feeding, enhancing efficiency and making it ideal for high-volume industrial applications. The choice between TIG and MIG welding depends on the required weld quality versus the need for speed and overall process efficiency.

Welding Precision and Quality

TIG welding delivers superior precision due to its controlled heat input and a non-consumable tungsten electrode, making it ideal for thin materials and intricate welds requiring minimal distortion. MIG welding offers faster weld speeds with ease of use but may sacrifice detailed control, leading to less refined weld seams. For applications demanding high-quality, visually clean, and structurally sound joints, TIG welding remains the preferred method in industries such as aerospace and automotive manufacturing.

Application: Best Uses for TIG and MIG Welding

TIG welding excels in precision applications such as aerospace, automotive, and artistic metalwork, particularly with thin materials like stainless steel and aluminum. MIG welding is best suited for heavy-duty construction, automotive repairs, and fabrication involving thicker metals, offering faster welds and easier operation. Both techniques complement each other by addressing distinct project requirements based on material type and weld quality.

Cost Considerations: Equipment and Operation

TIG welding equipment typically incurs higher initial costs due to specialized torches and power supplies, while MIG welding machines offer more affordable entry-level options suitable for beginners. Operational expenses differ as TIG welding requires more frequent tungsten electrode replacements and shielding gas usage, increasing consumable costs compared to MIG welding's more efficient wire feed and gas consumption. Maintenance for TIG equipment demands precise calibration and longer setup times, contributing to higher labor expenses versus MIG welding's streamlined operation and lower downtime.

Safety Measures for TIG and MIG Welding

TIG welding requires strict safety measures due to the intense ultraviolet light and inert gas exposure, necessitating the use of specialized welding helmets with appropriate shading, flame-resistant gloves, and protective clothing to prevent burns and eye damage. MIG welding produces more spatter and fumes, increasing the need for ventilation systems, respiratory protection, and fire-resistant attire to minimize inhalation risks and burn hazards. Both processes demand grounding of equipment and regular inspection of cables and connectors to prevent electrical shocks and ensure operator safety.

Choosing the Right Welding Method for Your Project

TIG welding offers precise control and produces high-quality, clean welds ideal for thin metals and intricate projects, while MIG welding provides faster deposition rates suitable for thicker materials and larger-scale fabrication. Consider material type, project complexity, and desired weld appearance when selecting between TIG and MIG welding methods. The right choice enhances efficiency, weld strength, and overall project success.

TIG welding vs MIG welding Infographic

productdif.com

productdif.com