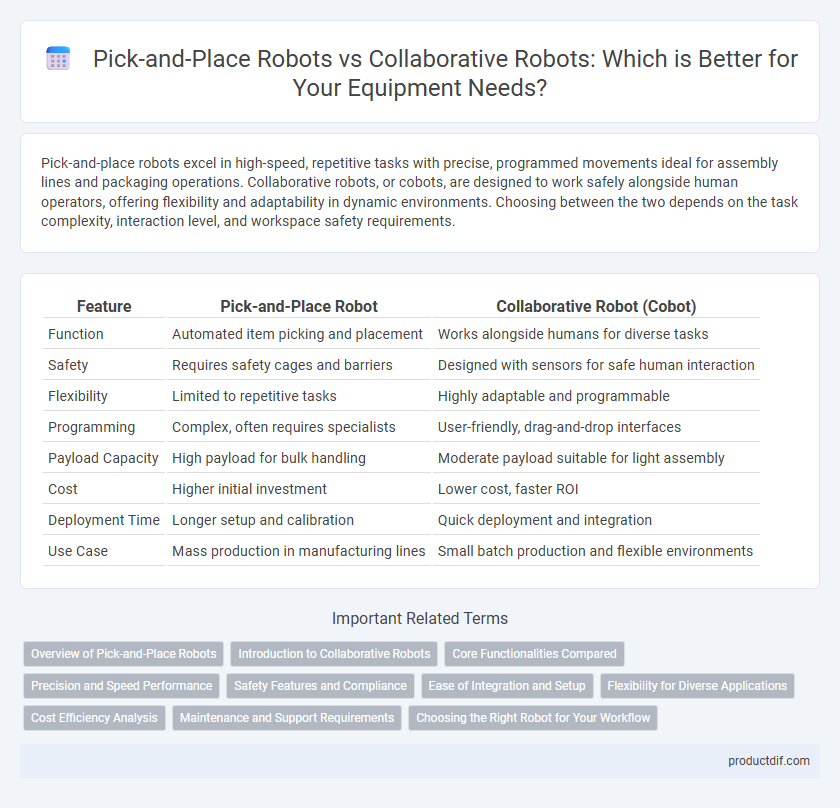

Pick-and-place robots excel in high-speed, repetitive tasks with precise, programmed movements ideal for assembly lines and packaging operations. Collaborative robots, or cobots, are designed to work safely alongside human operators, offering flexibility and adaptability in dynamic environments. Choosing between the two depends on the task complexity, interaction level, and workspace safety requirements.

Table of Comparison

| Feature | Pick-and-Place Robot | Collaborative Robot (Cobot) |

|---|---|---|

| Function | Automated item picking and placement | Works alongside humans for diverse tasks |

| Safety | Requires safety cages and barriers | Designed with sensors for safe human interaction |

| Flexibility | Limited to repetitive tasks | Highly adaptable and programmable |

| Programming | Complex, often requires specialists | User-friendly, drag-and-drop interfaces |

| Payload Capacity | High payload for bulk handling | Moderate payload suitable for light assembly |

| Cost | Higher initial investment | Lower cost, faster ROI |

| Deployment Time | Longer setup and calibration | Quick deployment and integration |

| Use Case | Mass production in manufacturing lines | Small batch production and flexible environments |

Overview of Pick-and-Place Robots

Pick-and-place robots are specialized automation equipment designed to efficiently transfer objects from one location to another within manufacturing or packaging processes, optimizing speed and precision. These robots typically feature articulated arms or gantry systems equipped with end-effectors tailored for gripping, positioning, and releasing items, enhancing workflow consistency and reducing human error. Their high repeatability, ease of programming, and adaptability to various industries make pick-and-place robots essential for repetitive tasks requiring rapid cycle times and minimal downtime.

Introduction to Collaborative Robots

Collaborative robots, also known as cobots, are designed to work safely alongside human operators without the need for extensive safety barriers, unlike traditional pick-and-place robots that typically operate in isolated environments. Equipped with advanced sensors and machine learning capabilities, cobots enhance flexibility and adaptability in manufacturing processes. Their compact design and user-friendly programming allow seamless integration into diverse production lines, improving efficiency and reducing operational costs.

Core Functionalities Compared

Pick-and-place robots excel in repetitive, high-speed tasks with precise object handling and placement, making them ideal for assembly lines and packaging. Collaborative robots, or cobots, offer flexibility with safe human-robot interaction, enabling them to perform complex tasks alongside workers without safety cages. Core functionalities of cobots include adaptive force control, easy programming, and sensor integration, while pick-and-place robots prioritize rapid cycle times and consistent accuracy.

Precision and Speed Performance

Pick-and-place robots excel in high-speed, repetitive tasks with precision often reaching sub-millimeter accuracy, making them ideal for assembly lines requiring rapid and consistent operations. Collaborative robots (cobots) offer a balance of precision and speed but prioritize safety and adaptability for working alongside humans, achieving slightly lower speeds but sufficient accuracy for complex, variable tasks. When maximum throughput and exact placement minute tolerances are critical, pick-and-place robots outperform; however, cobots provide enhanced flexibility and safety with reasonable precision and speed.

Safety Features and Compliance

Pick-and-place robots incorporate safety features such as physical barriers and emergency stop functions to comply with industrial safety standards like ISO 10218. Collaborative robots (cobots) are designed with advanced sensors, force limits, and safety-rated monitored stops, enabling safe interaction with human workers under ISO/TS 15066 guidelines. Both types ensure compliance, but cobots prioritize real-time responsiveness to human presence, enhancing workplace safety in dynamic environments.

Ease of Integration and Setup

Pick-and-place robots typically require more extensive programming and dedicated safety measures, making their integration and setup more complex compared to collaborative robots. Collaborative robots feature user-friendly interfaces and advanced sensors, enabling quicker deployment alongside human workers without the need for protective barriers. The ease of integration and setup of collaborative robots significantly reduces downtime and accelerates return on investment in manufacturing environments.

Flexibility for Diverse Applications

Pick-and-place robots excel in high-speed, repetitive tasks with precise accuracy, making them ideal for standardized production lines. Collaborative robots offer superior flexibility with easy programming and adaptability to various tasks, enabling seamless integration in dynamic environments. Their ability to safely work alongside human operators expands application possibilities across multiple industries.

Cost Efficiency Analysis

Pick-and-place robots typically offer higher cost efficiency in high-volume, repetitive tasks due to their faster cycle times and lower operational costs. Collaborative robots (cobots) provide flexibility and reduce integration expenses, making them cost-effective for small to medium production runs and diverse applications. Evaluating the total cost of ownership, including maintenance and programming, is essential to determine the best choice for specific manufacturing needs.

Maintenance and Support Requirements

Pick-and-place robots require specialized maintenance involving routine lubrication, calibration, and software updates to ensure high-speed precision and minimize downtime. Collaborative robots (cobots) feature simplified maintenance protocols with user-friendly diagnostics and modular components, reducing the need for expert intervention. Both types benefit from predictive maintenance technologies, but cobots typically demand less technical support due to their integrated safety features and flexible deployment.

Choosing the Right Robot for Your Workflow

Pick-and-place robots excel in high-speed, repetitive tasks with precise positioning, making them ideal for streamlined manufacturing workflows requiring minimal human intervention. Collaborative robots (cobots) offer flexibility and safe interaction with human operators, enhancing workflows that demand adaptability and shared workspace integration. Evaluating factors such as payload capacity, workspace layout, and task complexity ensures selecting the right robot maximizes efficiency and productivity in your specific industrial application.

Pick-and-place robot vs Collaborative robot Infographic

productdif.com

productdif.com