Analog gauges provide real-time, continuous readings through mechanical movement, offering intuitive visual feedback that is easy to interpret at a glance. Digital meters deliver precise, numerical measurements with enhanced accuracy, data logging capabilities, and often feature backlit displays for improved visibility in various lighting conditions. Choosing between analog gauges and digital meters depends on the specific application requirements, such as the need for detailed data analysis or quick, straightforward monitoring.

Table of Comparison

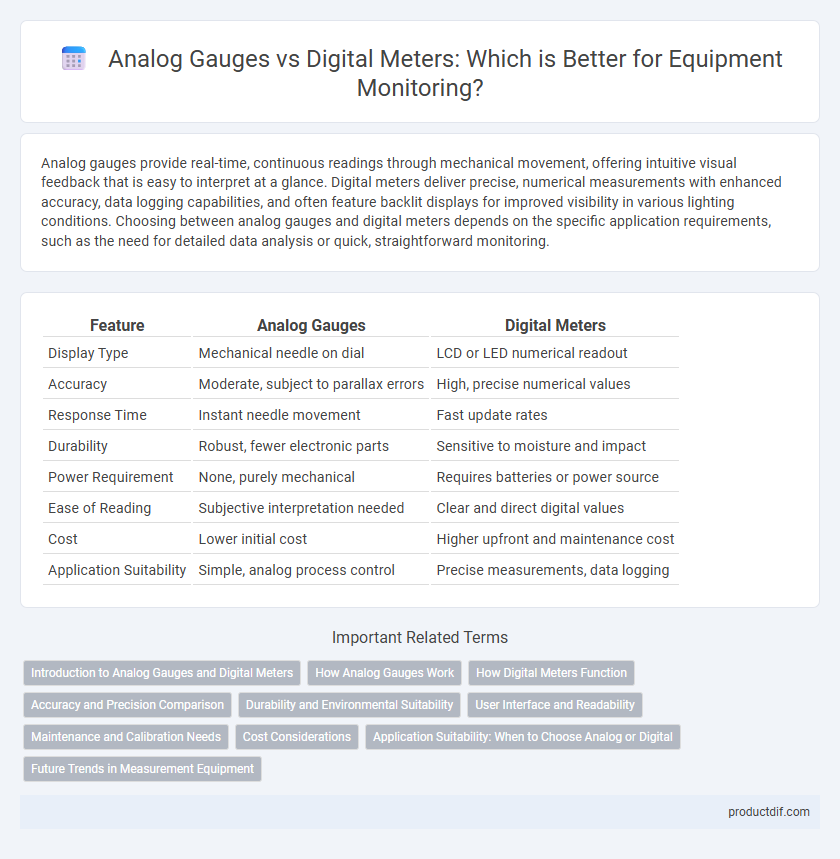

| Feature | Analog Gauges | Digital Meters |

|---|---|---|

| Display Type | Mechanical needle on dial | LCD or LED numerical readout |

| Accuracy | Moderate, subject to parallax errors | High, precise numerical values |

| Response Time | Instant needle movement | Fast update rates |

| Durability | Robust, fewer electronic parts | Sensitive to moisture and impact |

| Power Requirement | None, purely mechanical | Requires batteries or power source |

| Ease of Reading | Subjective interpretation needed | Clear and direct digital values |

| Cost | Lower initial cost | Higher upfront and maintenance cost |

| Application Suitability | Simple, analog process control | Precise measurements, data logging |

Introduction to Analog Gauges and Digital Meters

Analog gauges display measurements through continuous physical indicators such as needles moving over a dial, providing real-time visual feedback that is easily interpreted in dynamic environments. Digital meters convert analog signals into numerical data, offering precise readings with high resolution and often include features like data logging and remote monitoring. Both tools are essential in various industries, with analog gauges favored for quick visual checks and digital meters preferred for accuracy and advanced functionality.

How Analog Gauges Work

Analog gauges operate through mechanical movement, where a needle or pointer physically indicates a measurement on a dial. These gauges rely on sensors or transducers that convert physical quantities like pressure, temperature, or voltage into mechanical displacement. The deflection of the needle corresponds directly to the magnitude of the measured parameter, providing a continuous and real-time visual representation.

How Digital Meters Function

Digital meters function by converting analog signals into digital data through analog-to-digital converters (ADCs), enabling precise and clear readings. They utilize microprocessors to process input signals, displaying measurements on LCD or LED screens for easy interpretation. These meters often include advanced features such as data logging, auto-ranging, and connectivity for enhanced functionality and accuracy in monitoring equipment parameters.

Accuracy and Precision Comparison

Analog gauges provide continuous readings but often lack the high precision and consistency found in digital meters, which utilize advanced sensors and microprocessors for more exact measurements. Digital meters offer superior accuracy by minimizing human error and presenting clear numerical values, enhancing reliability in critical applications. Calibration stability in digital meters ensures consistent precision over time, making them ideal for equipment requiring stringent measurement standards.

Durability and Environmental Suitability

Analog gauges typically offer superior durability in harsh environments due to their mechanical construction and resistance to electromagnetic interference. Digital meters provide precise readings but may be more vulnerable to moisture, dust, and temperature extremes without adequate sealing and ruggedization. Choosing between analog and digital equipment depends on the operational conditions and the required balance between accuracy and robustness.

User Interface and Readability

Analog gauges feature a continuous dial and needle movement, providing an intuitive visual representation of measurements that is easily interpreted at a glance. Digital meters display precise numerical values on an LCD or LED screen, enhancing accuracy and reducing reading errors in low-light or high-vibration environments. User interface design in analog gauges prioritizes quick trend recognition, while digital meters emphasize exact data readability and integration with digital monitoring systems.

Maintenance and Calibration Needs

Analog gauges typically require more frequent maintenance and manual calibration to ensure accuracy, as their mechanical components are prone to wear and drift over time. Digital meters offer enhanced precision with automated calibration features, reducing the need for constant manual adjustments and minimizing downtime. Proper maintenance of both types involves regular inspection, but digital meters generally provide more consistent performance and easier diagnostics through integrated self-check systems.

Cost Considerations

Analog gauges generally have lower initial costs and simpler construction, making them more affordable for basic measurement needs. Digital meters often involve higher upfront expenses due to advanced technology and additional features like data logging and connectivity. Maintenance costs for analog gauges tend to be lower, but digital meters can reduce long-term expenses by providing more precise and reliable readings, minimizing downtime.

Application Suitability: When to Choose Analog or Digital

Analog gauges provide quick visual feedback and excel in environments requiring real-time trend observation without power dependency, making them ideal for industrial settings and mechanical systems. Digital meters offer high precision, data logging, and easy integration with automated control systems, suited for laboratory measurements and applications demanding exact numerical data. Choosing between analog and digital equipment depends on the necessity for durability and simplicity versus accuracy and advanced data capabilities.

Future Trends in Measurement Equipment

Future trends in measurement equipment highlight a shift towards digital meters due to their enhanced accuracy, data integration, and remote monitoring capabilities. Analog gauges remain valued for their simplicity and durability in harsh environments but are increasingly supplemented by smart sensors and IoT-enabled devices. Advanced analytics and real-time data processing are driving innovation, making digital measurement tools essential for predictive maintenance and automated systems.

Analog gauges vs Digital meters Infographic

productdif.com

productdif.com