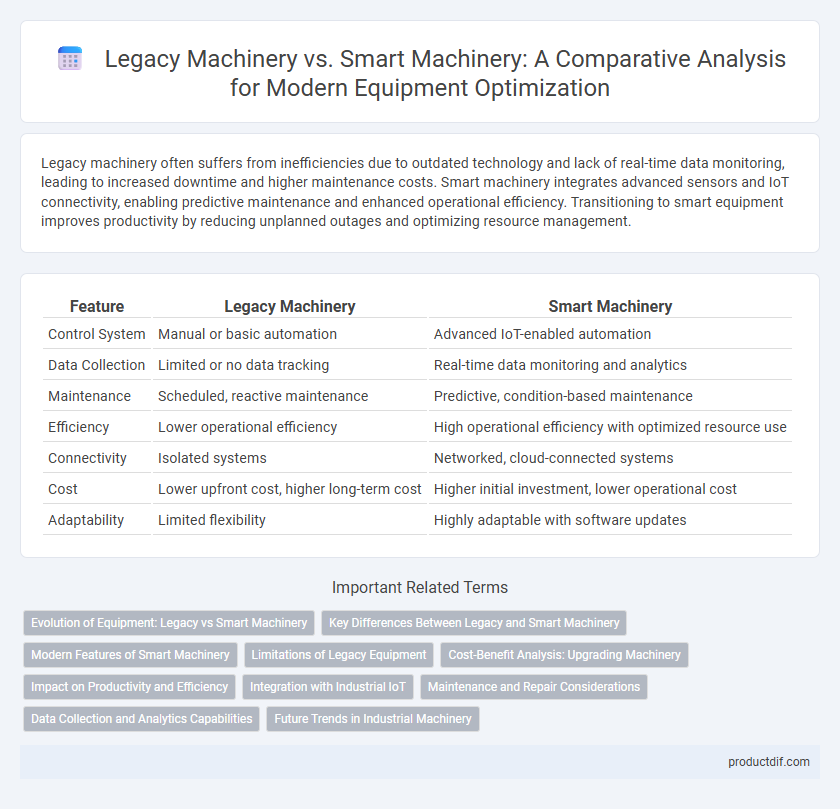

Legacy machinery often suffers from inefficiencies due to outdated technology and lack of real-time data monitoring, leading to increased downtime and higher maintenance costs. Smart machinery integrates advanced sensors and IoT connectivity, enabling predictive maintenance and enhanced operational efficiency. Transitioning to smart equipment improves productivity by reducing unplanned outages and optimizing resource management.

Table of Comparison

| Feature | Legacy Machinery | Smart Machinery |

|---|---|---|

| Control System | Manual or basic automation | Advanced IoT-enabled automation |

| Data Collection | Limited or no data tracking | Real-time data monitoring and analytics |

| Maintenance | Scheduled, reactive maintenance | Predictive, condition-based maintenance |

| Efficiency | Lower operational efficiency | High operational efficiency with optimized resource use |

| Connectivity | Isolated systems | Networked, cloud-connected systems |

| Cost | Lower upfront cost, higher long-term cost | Higher initial investment, lower operational cost |

| Adaptability | Limited flexibility | Highly adaptable with software updates |

Evolution of Equipment: Legacy vs Smart Machinery

Legacy machinery, often characterized by manual controls and limited automation, lacks the connectivity and data-processing capabilities that define smart machinery. Smart machinery integrates IoT sensors, AI-driven analytics, and predictive maintenance, significantly enhancing operational efficiency and reducing downtime. The evolution from legacy to smart equipment marks a shift towards intelligent manufacturing systems that optimize performance and enable real-time decision-making.

Key Differences Between Legacy and Smart Machinery

Legacy machinery typically relies on manual operation and basic mechanical systems, lacking real-time data integration and automation capabilities. Smart machinery incorporates advanced sensors, IoT connectivity, and AI-driven analytics to enable predictive maintenance, enhanced efficiency, and remote monitoring. The shift from legacy to smart machinery results in improved productivity, reduced downtime, and greater adaptability to evolving industrial demands.

Modern Features of Smart Machinery

Smart machinery integrates advanced sensors, IoT connectivity, and AI-driven analytics to optimize operational efficiency and predictive maintenance. These modern features enable real-time data monitoring, remote diagnostics, and adaptive control systems, reducing downtime and enhancing productivity. Unlike legacy machinery, smart equipment supports seamless integration with digital manufacturing ecosystems and facilitates automated decision-making processes.

Limitations of Legacy Equipment

Legacy machinery often suffers from limited connectivity and inability to integrate with modern IoT systems, resulting in suboptimal data collection and analysis. These machines typically require frequent manual maintenance, increasing downtime and operational costs. Furthermore, their outdated technology limits automation potential, reducing overall production efficiency and scalability.

Cost-Benefit Analysis: Upgrading Machinery

Upgrading legacy machinery to smart machinery involves evaluating the cost-benefit ratio, where initial investment and installation expenses are offset by long-term savings in maintenance and increased operational efficiency. Smart machinery integrates sensors and IoT technology, enabling predictive maintenance that reduces downtime and repair costs compared to traditional equipment. Companies benefit from enhanced data analytics and automation capabilities, leading to higher productivity and improved return on investment over time.

Impact on Productivity and Efficiency

Legacy machinery often suffers from limited automation and outdated controls, resulting in slower production rates and higher operational costs. Smart machinery integrates IoT sensors, real-time data analytics, and predictive maintenance, significantly enhancing operational efficiency and minimizing downtime. This technological advancement directly boosts overall productivity by optimizing workflows and resource usage.

Integration with Industrial IoT

Legacy machinery often lacks native compatibility with Industrial IoT protocols, requiring extensive retrofitting and custom interfaces for integration. Smart machinery is designed with built-in sensors and connectivity, enabling seamless data exchange and real-time analytics within Industrial IoT ecosystems. Efficient integration of smart machinery enhances operational efficiency, predictive maintenance, and asset management across manufacturing environments.

Maintenance and Repair Considerations

Legacy machinery often requires more frequent maintenance due to outdated components and lack of real-time diagnostics, leading to longer downtime and higher repair costs. Smart machinery integrates predictive maintenance technologies such as IoT sensors and machine learning algorithms, enabling proactive fault detection and reducing unplanned outages. Maintenance teams benefit from automated alerts and detailed data analytics, improving repair efficiency and extending equipment lifespan.

Data Collection and Analytics Capabilities

Legacy machinery typically relies on manual data collection methods or basic sensors with limited data granularity, leading to challenges in real-time monitoring and predictive maintenance. Smart machinery integrates advanced IoT sensors and edge computing, enabling continuous data streaming and sophisticated analytics that enhance operational efficiency and reduce downtime. Enhanced data integration from smart equipment supports predictive analytics, driving informed decision-making and optimized asset management.

Future Trends in Industrial Machinery

Future trends in industrial machinery emphasize the shift from legacy machinery to smart machinery equipped with IoT sensors, AI integration, and predictive maintenance capabilities. Smart machinery enables real-time data analytics, enhances operational efficiency, and reduces downtime through automated diagnostics. Adoption of digital twins and machine learning algorithms is accelerating the transformation toward fully connected, autonomous manufacturing ecosystems.

Legacy machinery vs Smart machinery Infographic

productdif.com

productdif.com