Manual calibration relies on skilled technicians to adjust equipment settings based on visual inspections and measurement tools, ensuring precision through hands-on adjustments. Automated calibration uses software and sensors to continuously monitor and adjust equipment, enhancing accuracy while reducing human error and downtime. Choosing between manual and automated calibration depends on the required precision, budget, and frequency of adjustments needed for optimal equipment performance.

Table of Comparison

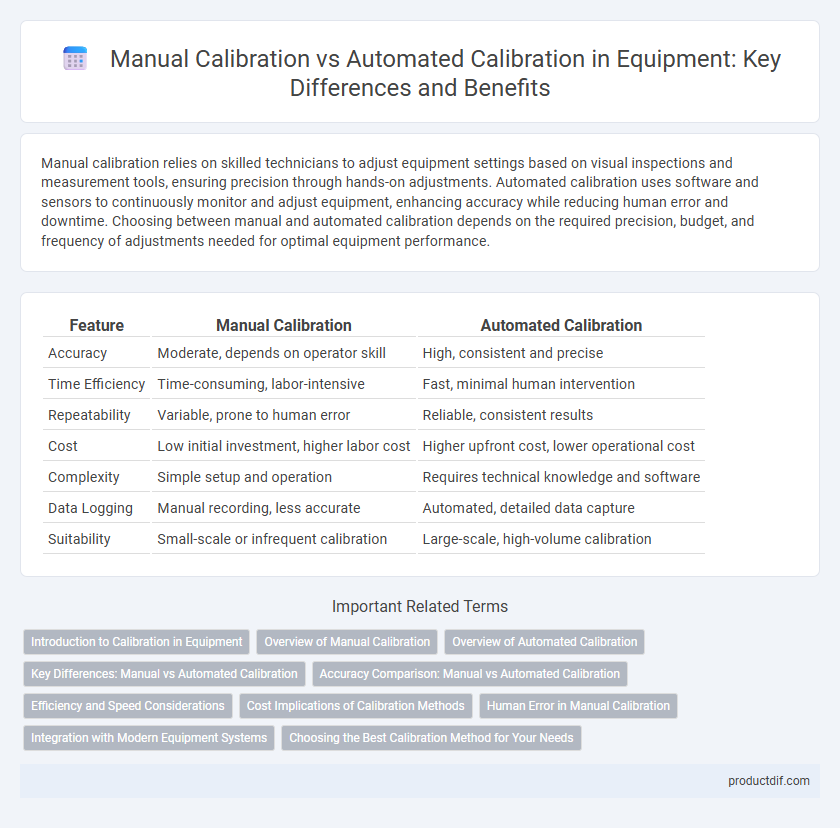

| Feature | Manual Calibration | Automated Calibration |

|---|---|---|

| Accuracy | Moderate, depends on operator skill | High, consistent and precise |

| Time Efficiency | Time-consuming, labor-intensive | Fast, minimal human intervention |

| Repeatability | Variable, prone to human error | Reliable, consistent results |

| Cost | Low initial investment, higher labor cost | Higher upfront cost, lower operational cost |

| Complexity | Simple setup and operation | Requires technical knowledge and software |

| Data Logging | Manual recording, less accurate | Automated, detailed data capture |

| Suitability | Small-scale or infrequent calibration | Large-scale, high-volume calibration |

Introduction to Calibration in Equipment

Calibration ensures equipment accuracy by comparing measurements against a known standard. Manual calibration involves human intervention to adjust settings, often requiring skilled technicians and time-consuming procedures. Automated calibration uses software and sensors to streamline the process, enhancing precision and reducing downtime.

Overview of Manual Calibration

Manual calibration involves operators physically adjusting equipment settings using reference standards and measurement tools to ensure accuracy. This process relies heavily on human expertise, precision instruments, and detailed procedural steps to align device outputs with specified tolerances. Manual calibration is essential for complex equipment where automated systems may lack the flexibility to address unique or nuanced calibration requirements.

Overview of Automated Calibration

Automated calibration streamlines equipment accuracy by using software-driven processes to adjust instruments without manual intervention, significantly reducing human error and downtime. This method employs sensors and feedback systems to continuously monitor and calibrate devices in real-time, ensuring consistent performance and compliance with industry standards. Automated calibration enhances productivity by enabling precise, repeatable adjustments across multiple instruments, minimizing the need for skilled technicians.

Key Differences: Manual vs Automated Calibration

Manual calibration requires skilled technicians to adjust equipment settings based on visual indicators or measurement tools, offering high flexibility but increased risk of human error and longer calibration times. Automated calibration utilizes software and sensors to perform precise adjustments quickly, enhancing consistency, repeatability, and reducing downtime in complex or high-volume environments. The key differences lie in the balance between manual expertise and automation efficiency, impacting accuracy, speed, and resource allocation in equipment maintenance.

Accuracy Comparison: Manual vs Automated Calibration

Automated calibration offers higher accuracy compared to manual calibration by minimizing human errors and ensuring consistent measurement conditions. Precision instruments integrated with automated systems can detect and correct minute deviations that manual methods may overlook. Data from multiple calibration cycles show that automated calibration improves repeatability and reliability, leading to enhanced equipment performance.

Efficiency and Speed Considerations

Manual calibration requires significant operator time and expertise, often leading to longer equipment downtime and slower adjustment processes. Automated calibration utilizes advanced software and sensors to perform rapid, precise calibrations, significantly reducing operational disruptions and improving throughput. Efficiency gains from automated methods include consistent accuracy and repeatability, minimizing human error and accelerating equipment readiness.

Cost Implications of Calibration Methods

Manual calibration typically involves higher labor costs due to the need for skilled technicians and longer adjustment times, increasing overall expenses. Automated calibration reduces labor costs by utilizing software-driven processes and precision machinery, enabling faster and more consistent results. Equipment downtime is minimized with automated methods, further lowering cost implications compared to manual calibration.

Human Error in Manual Calibration

Manual calibration is highly susceptible to human error, which can lead to inconsistent measurements and reduced equipment reliability. Variations in technician skill, attention, and environmental factors contribute to inaccuracies during manual adjustments. Automated calibration minimizes these risks by using precise algorithms and standardized procedures to ensure repeatable and accurate calibration results.

Integration with Modern Equipment Systems

Manual calibration offers hands-on control but often lacks seamless integration with modern equipment systems, limiting real-time data exchange and automation capabilities. Automated calibration enhances precision and consistency through software-driven processes that easily integrate with IoT-enabled devices and advanced monitoring platforms. This integration enables streamlined workflows, continuous calibration tracking, and improved equipment performance across industrial applications.

Choosing the Best Calibration Method for Your Needs

Manual calibration offers precise control by allowing operators to adjust equipment settings based on real-time feedback and specific requirements. Automated calibration increases efficiency by using programmed algorithms and sensors to perform adjustments quickly and consistently, reducing human error. Selecting the best calibration method depends on factors such as the complexity of the equipment, required accuracy, available resources, and frequency of recalibration.

Manual calibration vs Automated calibration Infographic

productdif.com

productdif.com