RFID tagging offers faster and more accurate inventory tracking compared to barcode scanning by enabling wireless data capture without line-of-sight requirements. Unlike barcodes, RFID tags can store more information and withstand harsh environments, enhancing durability and reliability in equipment management. The ability of RFID systems to read multiple tags simultaneously significantly improves operational efficiency over traditional barcode scanning methods.

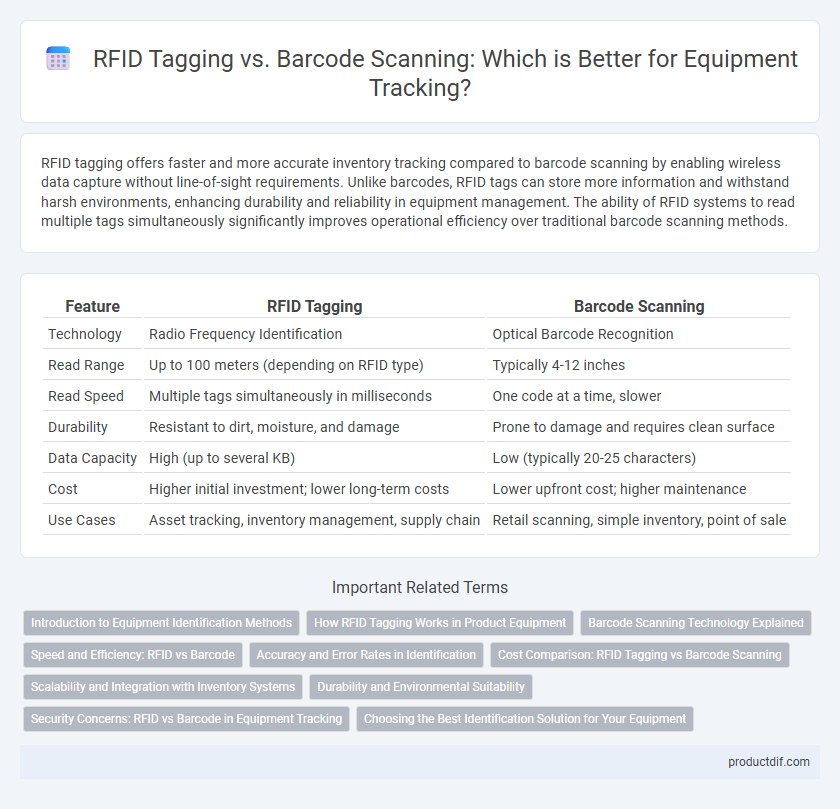

Table of Comparison

| Feature | RFID Tagging | Barcode Scanning |

|---|---|---|

| Technology | Radio Frequency Identification | Optical Barcode Recognition |

| Read Range | Up to 100 meters (depending on RFID type) | Typically 4-12 inches |

| Read Speed | Multiple tags simultaneously in milliseconds | One code at a time, slower |

| Durability | Resistant to dirt, moisture, and damage | Prone to damage and requires clean surface |

| Data Capacity | High (up to several KB) | Low (typically 20-25 characters) |

| Cost | Higher initial investment; lower long-term costs | Lower upfront cost; higher maintenance |

| Use Cases | Asset tracking, inventory management, supply chain | Retail scanning, simple inventory, point of sale |

Introduction to Equipment Identification Methods

RFID tagging employs radio frequency signals to automatically identify and track equipment, offering faster data acquisition and greater accuracy compared to traditional barcode scanning, which relies on optical line-of-sight technology. RFID systems enable simultaneous scanning of multiple items without direct contact, enhancing operational efficiency in inventory management and asset tracking. Barcode scanning remains cost-effective for simple identification needs but falls short in environments requiring rapid, bulk data capture and real-time visibility.

How RFID Tagging Works in Product Equipment

RFID tagging uses radio frequency signals to automatically identify and track product equipment through embedded microchips and antennas, enabling real-time data capture without direct line-of-sight. Unlike barcode scanning, RFID tags store more detailed information and can be read from multiple items simultaneously, increasing efficiency in inventory management. The technology supports enhanced asset tracking accuracy and reduces manual scanning errors in various industrial environments.

Barcode Scanning Technology Explained

Barcode scanning technology uses optical scanning to read patterns of black and white lines representing alphanumeric data, enabling quick product identification and inventory management. This technology relies on laser or camera-based scanners to decode barcode information, which is then processed by inventory systems for accurate tracking and sales data collection. Barcode scanning is cost-effective, widely adopted, and supports high-speed scanning in various equipment and retail environments.

Speed and Efficiency: RFID vs Barcode

RFID tagging significantly outperforms barcode scanning in speed and efficiency by enabling rapid, simultaneous reading of multiple tags without requiring line-of-sight, reducing scanning time from minutes to seconds in large inventory settings. RFID systems streamline asset tracking processes, minimize human errors, and boost operational throughput with automated data capture, whereas barcode scanning demands manual alignment and slower individual scans. The integration of RFID technology enhances real-time visibility and drastically improves workflow efficiency across supply chains and warehouse operations.

Accuracy and Error Rates in Identification

RFID tagging significantly improves accuracy in equipment identification by enabling non-line-of-sight scanning and simultaneous reading of multiple tags, reducing human error compared to barcode scanning. Barcode systems rely on direct line-of-sight and manual scanning, increasing the likelihood of misreads and higher error rates in fast-paced or complex environments. Studies show RFID reduces error rates to less than 1%, while barcode scanning error rates can exceed 10% in high-volume operations.

Cost Comparison: RFID Tagging vs Barcode Scanning

RFID tagging involves higher initial costs due to the price of tags, readers, and software integration, with tags typically ranging from $0.10 to $0.50 per unit, while barcode scanning has lower upfront expenses, with barcode labels costing only a few cents each and scanners priced from $100 to $1,000. Despite the higher setup cost, RFID offers long-term savings through faster inventory processes and reduced labor, which can lead to a return on investment within 12-18 months compared to barcode systems that require manual line-of-sight scanning. Maintenance and replacement expenses for RFID hardware tend to be higher than barcode equipment, but RFID's durability and reusability help mitigate recurring costs, making cost-effectiveness dependent on scale and operational complexity.

Scalability and Integration with Inventory Systems

RFID tagging offers superior scalability compared to barcode scanning by enabling simultaneous reading of multiple items, significantly speeding up large-scale inventory processes. Its integration with modern inventory management systems supports real-time data updates and accurate asset tracking, enhancing operational efficiency. Barcode scanning, while cost-effective for smaller inventories, faces limitations in bulk processing and typically requires manual line-of-sight scanning, impacting scalability and integration capabilities.

Durability and Environmental Suitability

RFID tagging offers superior durability compared to barcode scanning, as RFID tags are resistant to wear, moisture, and chemicals, making them ideal for harsh environments. Unlike barcodes, which can become unreadable when scratched or dirty, RFID tags maintain performance in extreme temperatures and outdoor conditions. This environmental robustness ensures reliable tracking and identification in industries such as manufacturing, logistics, and healthcare.

Security Concerns: RFID vs Barcode in Equipment Tracking

RFID tagging offers enhanced security in equipment tracking by using encrypted data transmission and unique identifiers, reducing the risk of counterfeiting and unauthorized access. Barcode scanning relies on visible, easily duplicated labels, making it more vulnerable to tampering and data theft. Advanced RFID systems support authentication protocols that protect sensitive equipment information from interception and manipulation.

Choosing the Best Identification Solution for Your Equipment

RFID tagging provides faster, contactless scanning and greater data capacity compared to barcode scanning, making it ideal for real-time equipment tracking and inventory management. Barcode scanning remains cost-effective and simple to implement, suitable for environments where quick visual identification is sufficient. Selecting the best identification solution depends on factors like budget, accuracy requirements, environmental conditions, and the complexity of data needed for equipment management.

RFID tagging vs Barcode scanning Infographic

productdif.com

productdif.com