Off-the-shelf equipment offers immediate availability and cost efficiency, making it ideal for standard applications with predictable requirements. Custom-built equipment provides tailored solutions designed to meet specific operational demands, enhancing performance and adaptability in unique environments. Choosing between the two depends on balancing budget constraints, timeline urgency, and the need for specialized functionality.

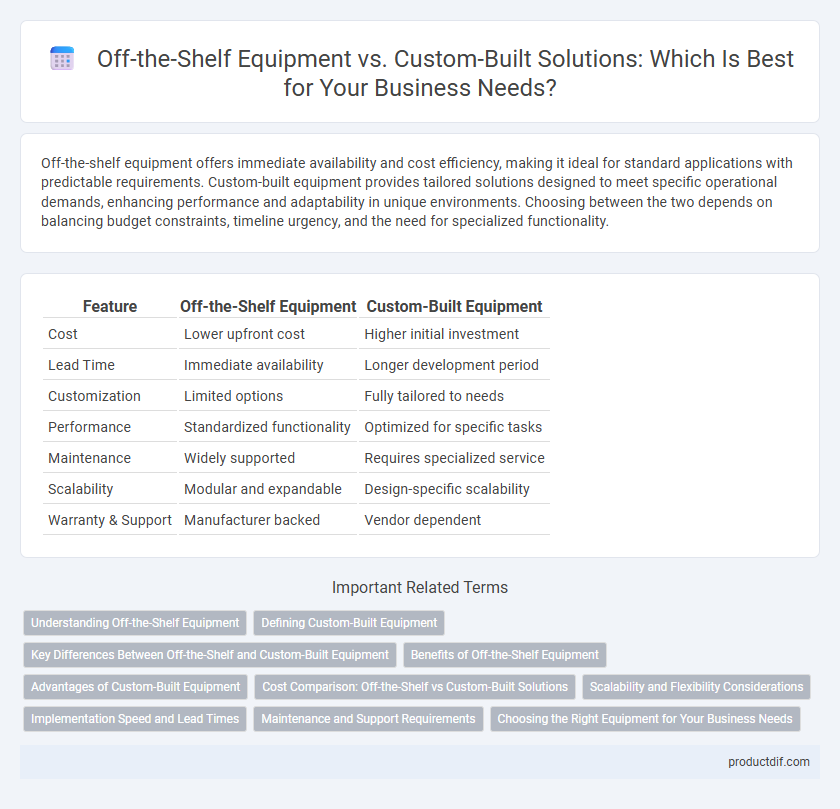

Table of Comparison

| Feature | Off-the-Shelf Equipment | Custom-Built Equipment |

|---|---|---|

| Cost | Lower upfront cost | Higher initial investment |

| Lead Time | Immediate availability | Longer development period |

| Customization | Limited options | Fully tailored to needs |

| Performance | Standardized functionality | Optimized for specific tasks |

| Maintenance | Widely supported | Requires specialized service |

| Scalability | Modular and expandable | Design-specific scalability |

| Warranty & Support | Manufacturer backed | Vendor dependent |

Understanding Off-the-Shelf Equipment

Off-the-shelf equipment refers to standard, pre-manufactured products readily available for immediate use without customization, making them cost-effective and quick to deploy. These products are designed to meet general industry standards and are suitable for applications where specific requirements are minimal. Leveraging off-the-shelf equipment reduces lead times and simplifies maintenance due to widespread availability of parts and expertise.

Defining Custom-Built Equipment

Custom-built equipment is designed and manufactured to meet specific operational requirements and unique business processes, offering tailored solutions that off-the-shelf equipment cannot provide. It integrates specialized materials, components, and technologies to optimize performance, efficiency, and durability for niche applications. This approach ensures alignment with precise standards, enhancing productivity and reducing integration challenges in complex workflows.

Key Differences Between Off-the-Shelf and Custom-Built Equipment

Off-the-shelf equipment offers immediate availability and standardized features suitable for general applications, while custom-built equipment is designed to meet specific operational requirements with tailored functionalities. Off-the-shelf options typically provide lower initial costs and faster deployment, contrasting with custom-built solutions that require higher investment but ensure optimized performance and scalability. Maintenance and upgrades for off-the-shelf equipment are often more straightforward due to manufacturer support, whereas custom-built equipment may need specialized servicing aligned with its unique design.

Benefits of Off-the-Shelf Equipment

Off-the-shelf equipment offers immediate availability and cost-effectiveness, reducing downtime and capital expenditure for businesses. Standardized designs ensure compatibility with existing systems, facilitating easier installation and maintenance. High-volume production often results in reliable performance and access to extensive customer support and documentation.

Advantages of Custom-Built Equipment

Custom-built equipment offers tailored solutions that precisely meet specific operational requirements, enhancing efficiency and reducing waste. It often provides better integration with existing systems and improved scalability compared to off-the-shelf options. Companies benefit from increased reliability and longevity due to specialized design and higher quality components.

Cost Comparison: Off-the-Shelf vs Custom-Built Solutions

Off-the-shelf equipment typically offers lower initial costs due to mass production and standardized features, making it a cost-effective choice for businesses with budget constraints. Custom-built equipment requires higher upfront investment because of tailored design, specialized materials, and development time, but it can lead to long-term savings through enhanced efficiency and reduced operational downtime. Evaluating total cost of ownership, including maintenance and scalability, is essential when comparing off-the-shelf and custom-built solutions.

Scalability and Flexibility Considerations

Off-the-shelf equipment offers immediate scalability with standardized modules that support rapid deployment and easy integration across various systems. Custom-built equipment provides enhanced flexibility, allowing tailored solutions to specific operational needs and future-proofing scalability through modular design adjustments. Balancing cost-efficiency and adaptability is crucial when choosing between off-the-shelf and custom-built equipment for scalable infrastructure.

Implementation Speed and Lead Times

Off-the-shelf equipment offers rapid implementation speed and significantly shorter lead times due to its immediate availability and standardized production. Custom-built equipment requires longer lead times as it involves tailored design, engineering, and manufacturing processes to meet specific requirements. Selecting off-the-shelf solutions accelerates deployment in time-sensitive projects, while custom-built options, despite extended lead times, provide precise functionality and integration for unique applications.

Maintenance and Support Requirements

Off-the-shelf equipment typically benefits from standardized maintenance protocols and widespread support networks, reducing downtime and service costs. Custom-built equipment demands specialized maintenance expertise and tailored support systems, potentially increasing complexity and expenses. Evaluating long-term serviceability and access to replacement parts is critical when choosing between these equipment options.

Choosing the Right Equipment for Your Business Needs

Off-the-shelf equipment offers immediate availability and cost-effectiveness, making it ideal for businesses with standardized processes and tight budgets. Custom-built equipment provides tailored solutions that optimize operational efficiency and meet specific industry requirements, suitable for companies seeking competitive advantages through specialized functionality. Evaluating factors such as production scale, budget constraints, and long-term maintenance needs ensures the selection of equipment aligns precisely with your business objectives.

Off-the-Shelf Equipment vs Custom-Built Equipment Infographic

productdif.com

productdif.com