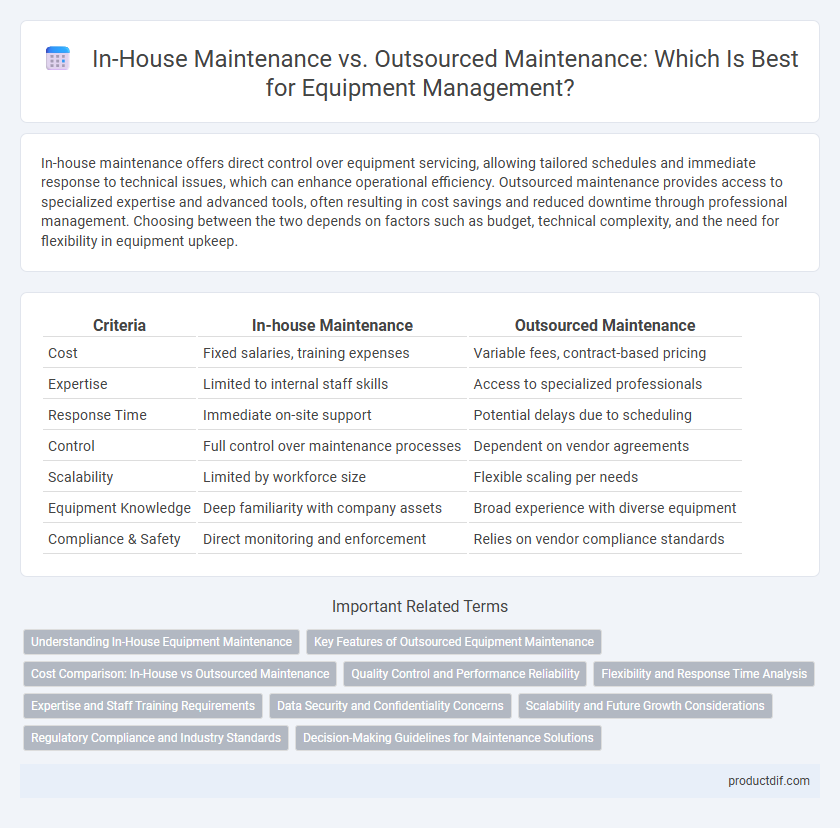

In-house maintenance offers direct control over equipment servicing, allowing tailored schedules and immediate response to technical issues, which can enhance operational efficiency. Outsourced maintenance provides access to specialized expertise and advanced tools, often resulting in cost savings and reduced downtime through professional management. Choosing between the two depends on factors such as budget, technical complexity, and the need for flexibility in equipment upkeep.

Table of Comparison

| Criteria | In-house Maintenance | Outsourced Maintenance |

|---|---|---|

| Cost | Fixed salaries, training expenses | Variable fees, contract-based pricing |

| Expertise | Limited to internal staff skills | Access to specialized professionals |

| Response Time | Immediate on-site support | Potential delays due to scheduling |

| Control | Full control over maintenance processes | Dependent on vendor agreements |

| Scalability | Limited by workforce size | Flexible scaling per needs |

| Equipment Knowledge | Deep familiarity with company assets | Broad experience with diverse equipment |

| Compliance & Safety | Direct monitoring and enforcement | Relies on vendor compliance standards |

Understanding In-House Equipment Maintenance

In-house equipment maintenance offers direct control over the upkeep process, enabling faster response times and tailored service for specialized machinery. It requires skilled technicians, dedicated resources, and continuous training to ensure optimal performance and minimize downtime. Companies achieve higher asset reliability and cost predictability by managing maintenance internally, especially for critical equipment.

Key Features of Outsourced Equipment Maintenance

Outsourced equipment maintenance offers access to specialized technicians and advanced diagnostic tools that ensure prompt and accurate repairs, reducing downtime significantly. Contractual service agreements provide predictable maintenance costs and scalability aligned with operational demands. Outsourcing also allows companies to leverage industry best practices and the latest technology updates without investing heavily in internal resources.

Cost Comparison: In-House vs Outsourced Maintenance

In-house maintenance typically incurs higher fixed costs due to salaries, training, and equipment expenses, yet offers greater control and immediate response times for equipment repairs. Outsourced maintenance reduces overhead by leveraging specialized service providers who bring expertise and economies of scale, often resulting in variable costs aligned with service contracts. Evaluating the total cost of ownership, including downtime risks and quality of maintenance, is essential for optimizing expenditures between in-house teams and external vendors.

Quality Control and Performance Reliability

In-house maintenance offers direct oversight of quality control, ensuring equipment is serviced according to company-specific standards and protocols. This hands-on approach typically enhances performance reliability by allowing immediate adjustments and continuous monitoring tailored to operational needs. Outsourced maintenance can provide specialized expertise but may face challenges in maintaining consistent quality control and responsiveness, potentially impacting long-term equipment performance.

Flexibility and Response Time Analysis

In-house maintenance offers greater flexibility through immediate access to skilled technicians and real-time problem-solving, significantly reducing equipment downtime. Outsourced maintenance may face longer response times due to scheduling and travel, potentially delaying critical repairs. Evaluating response time data reveals that in-house teams often outperform external providers in urgent maintenance scenarios, enhancing operational continuity.

Expertise and Staff Training Requirements

In-house maintenance requires substantial investment in staff training and continuous skill development to ensure expertise in handling complex equipment issues. Outsourced maintenance leverages specialized providers with certified technicians who bring advanced knowledge and up-to-date industry skills, reducing internal training burdens. Organizations focusing on operational efficiency often prefer outsourcing to access expert services without the overhead of maintaining extensive in-house expertise.

Data Security and Confidentiality Concerns

In-house maintenance offers greater control over data security and confidentiality, as sensitive information remains within the company's secured network and under direct employee supervision. Outsourced maintenance poses risks of data breaches or unauthorized access due to third-party handling, especially if vendors lack robust cybersecurity protocols and non-disclosure agreements. Companies must evaluate vendor security certifications such as ISO 27001 and implement strict access controls to safeguard proprietary equipment data during outsourced maintenance.

Scalability and Future Growth Considerations

In-house maintenance allows for immediate scalability by leveraging existing personnel familiar with specific equipment, ensuring quicker response times and customized upkeep. Outsourced maintenance offers flexibility in scaling resources up or down without the constraints of hiring or training, supporting rapid growth or seasonal demand shifts. Future growth considerations favor outsourced services when expanding into new equipment types or locations, while in-house maintenance suits steady operations with consistent equipment needs.

Regulatory Compliance and Industry Standards

In-house maintenance ensures direct control over adherence to regulatory compliance and industry standards, allowing immediate updates and customization to company-specific protocols. Outsourced maintenance offers access to specialized expertise and certified technicians who are well-versed in evolving regulations and standardized procedures. Companies must evaluate their capacity to consistently meet compliance requirements before deciding between internal teams or external service providers.

Decision-Making Guidelines for Maintenance Solutions

Evaluating in-house versus outsourced maintenance requires analyzing factors such as cost efficiency, expertise availability, and operational impact to determine the optimal approach. Organizations should assess the complexity of equipment, workforce skill levels, and response time requirements to align maintenance strategies with business objectives. Data-driven decision-making, incorporating total cost of ownership and risk management, enhances long-term equipment reliability and asset performance.

In-house maintenance vs Outsourced maintenance Infographic

productdif.com

productdif.com