Manual calibration requires skilled operators to adjust equipment settings for precise measurements, ensuring accuracy through hands-on control. Auto calibration uses built-in sensors and software algorithms to automatically fine-tune equipment parameters, enhancing efficiency and reducing human error. Choosing between manual and auto calibration depends on the complexity of the equipment and the desired balance between precision and operational speed.

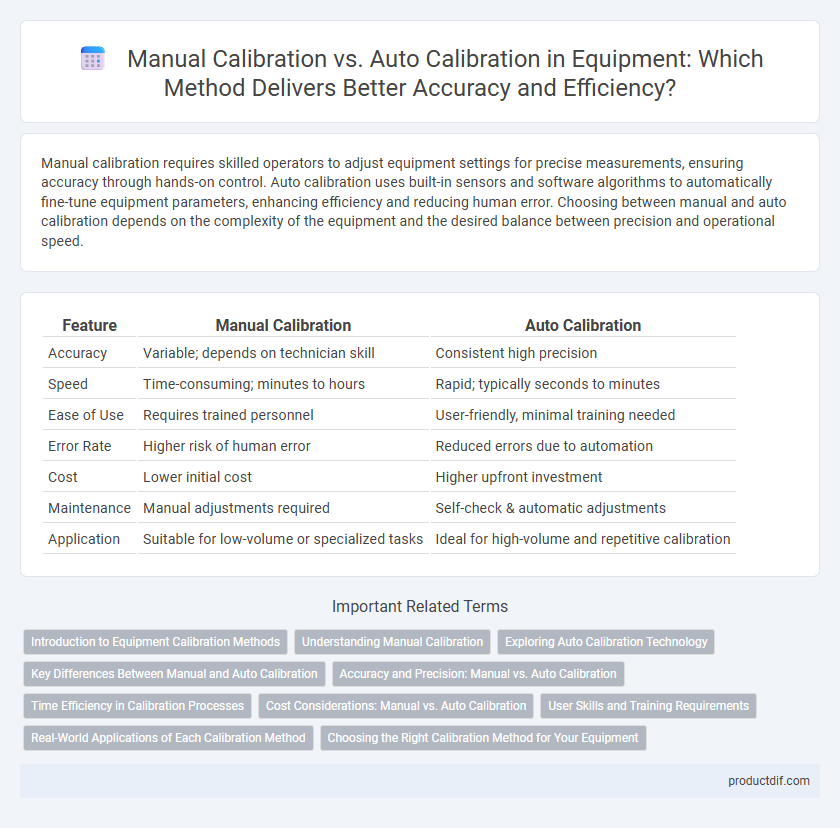

Table of Comparison

| Feature | Manual Calibration | Auto Calibration |

|---|---|---|

| Accuracy | Variable; depends on technician skill | Consistent high precision |

| Speed | Time-consuming; minutes to hours | Rapid; typically seconds to minutes |

| Ease of Use | Requires trained personnel | User-friendly, minimal training needed |

| Error Rate | Higher risk of human error | Reduced errors due to automation |

| Cost | Lower initial cost | Higher upfront investment |

| Maintenance | Manual adjustments required | Self-check & automatic adjustments |

| Application | Suitable for low-volume or specialized tasks | Ideal for high-volume and repetitive calibration |

Introduction to Equipment Calibration Methods

Equipment calibration methods ensure precision by aligning instrument measurements with known standards, enhancing accuracy in various applications. Manual calibration involves hands-on adjustments using reference tools, requiring skilled personnel and consuming more time but allowing detailed control. Auto calibration utilizes built-in sensors and software algorithms for faster, consistent, and less error-prone calibration, improving efficiency in modern equipment maintenance.

Understanding Manual Calibration

Manual calibration requires technicians to adjust equipment settings based on precise measurements and standardized reference points, ensuring accuracy tailored to specific operational conditions. This process allows for direct control over calibration parameters, which can be essential in specialized or complex instruments where automated systems may lack flexibility. Understanding manual calibration involves recognizing its reliance on expert interpretation and fine-tuning to maintain equipment performance and reliability.

Exploring Auto Calibration Technology

Auto calibration technology enhances equipment accuracy by using integrated sensors and algorithms to adjust settings without manual input. This system reduces human error, ensures consistent performance, and speeds up the calibration process. Innovations in auto calibration increasingly incorporate machine learning to adapt to environmental changes and equipment wear over time.

Key Differences Between Manual and Auto Calibration

Manual calibration requires operators to adjust equipment settings based on reference standards, often involving more time and human error risk, while auto calibration uses embedded sensors and software to automatically fine-tune parameters with higher precision and consistency. Manual methods provide flexibility for complex or irregular calibration tasks, whereas auto calibration ensures repeatability and reduces downtime in routine processes. Equipment with auto calibration typically supports real-time monitoring and adaptive adjustments, improving overall operational efficiency compared to manual calibration workflows.

Accuracy and Precision: Manual vs. Auto Calibration

Manual calibration relies on technician skill and visual inspection, often resulting in variability and reduced precision compared to auto calibration. Auto calibration utilizes built-in sensors and algorithms to consistently achieve higher accuracy and repeatability, minimizing human error. Precision in auto calibration surpasses manual methods, ensuring reliable and standardized equipment performance.

Time Efficiency in Calibration Processes

Auto calibration significantly reduces the time required for equipment setup by automating measurement adjustments and eliminating manual intervention. Manual calibration demands skilled technicians and can be time-consuming due to repetitive, precise adjustments and verification steps. Time efficiency in calibration processes improves productivity and minimizes equipment downtime, making auto calibration the preferred choice in high-throughput environments.

Cost Considerations: Manual vs. Auto Calibration

Manual calibration typically involves lower initial costs due to minimal equipment requirements but incurs higher labor expenses over time, impacting overall cost efficiency. Auto calibration systems require a significant upfront investment in advanced technology but reduce human error and ongoing labor costs, resulting in long-term savings. Evaluating the total cost of ownership, including equipment depreciation, maintenance, and productivity gains, is essential for selecting the most cost-effective calibration method.

User Skills and Training Requirements

Manual calibration demands advanced user skills and extensive training to accurately adjust equipment settings and interpret measurement results. Auto calibration minimizes the need for specialized knowledge by automating the calibration process, making it accessible to users with minimal technical expertise. Training requirements for auto calibration primarily focus on equipment operation and software interfaces rather than in-depth calibration theory.

Real-World Applications of Each Calibration Method

Manual calibration is often preferred in precision equipment like laboratory instruments where human expertise ensures accurate adjustments tailored to specific experimental conditions. Auto calibration is widely used in industrial settings such as manufacturing lines and environmental sensors, offering rapid, consistent adjustments that minimize downtime and maintain operational efficiency. Each method's suitability depends on factors like equipment complexity, required accuracy, and frequency of calibration needed in real-world scenarios.

Choosing the Right Calibration Method for Your Equipment

Choosing the right calibration method for your equipment depends on accuracy requirements and operational efficiency. Manual calibration offers precise control and is ideal for specialized or sensitive instruments but requires skilled technicians and more time. Auto calibration enhances consistency and speed, making it suitable for routine maintenance and large-scale operations where minimizing downtime is critical.

Manual calibration vs Auto calibration Infographic

productdif.com

productdif.com