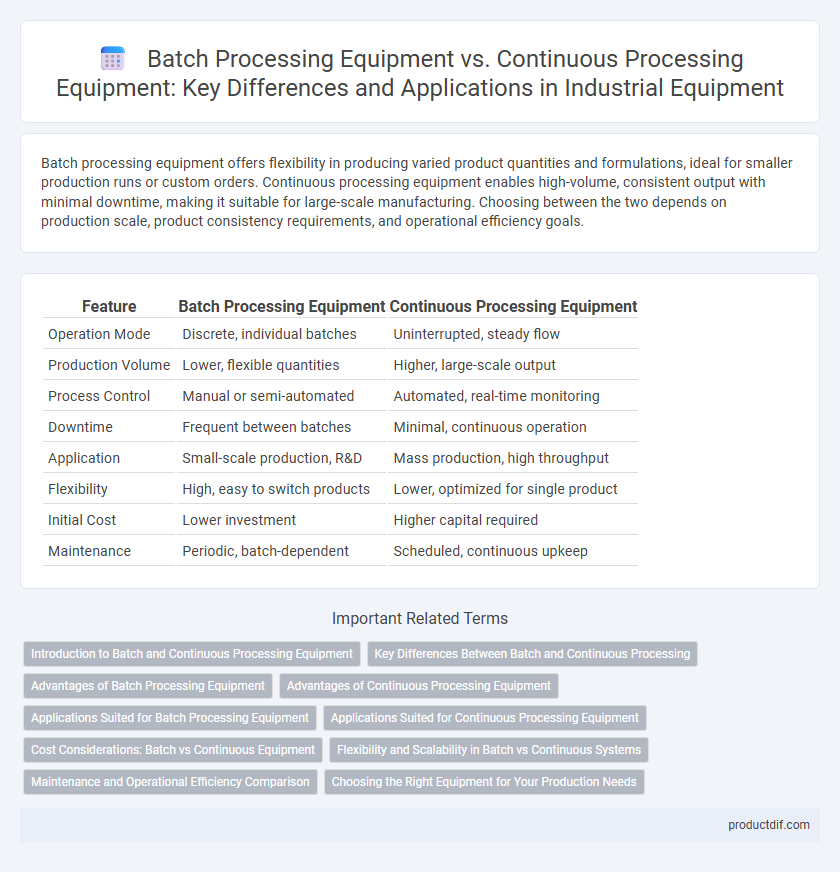

Batch processing equipment offers flexibility in producing varied product quantities and formulations, ideal for smaller production runs or custom orders. Continuous processing equipment enables high-volume, consistent output with minimal downtime, making it suitable for large-scale manufacturing. Choosing between the two depends on production scale, product consistency requirements, and operational efficiency goals.

Table of Comparison

| Feature | Batch Processing Equipment | Continuous Processing Equipment |

|---|---|---|

| Operation Mode | Discrete, individual batches | Uninterrupted, steady flow |

| Production Volume | Lower, flexible quantities | Higher, large-scale output |

| Process Control | Manual or semi-automated | Automated, real-time monitoring |

| Downtime | Frequent between batches | Minimal, continuous operation |

| Application | Small-scale production, R&D | Mass production, high throughput |

| Flexibility | High, easy to switch products | Lower, optimized for single product |

| Initial Cost | Lower investment | Higher capital required |

| Maintenance | Periodic, batch-dependent | Scheduled, continuous upkeep |

Introduction to Batch and Continuous Processing Equipment

Batch processing equipment handles production in distinct, separate quantities, allowing flexibility and customization for smaller volume manufacturing. Continuous processing equipment operates nonstop, ideal for large-scale, high-volume production with consistent quality and efficiency. Choosing between batch and continuous processing depends on product type, production volume, and process control requirements.

Key Differences Between Batch and Continuous Processing

Batch processing equipment handles materials in discrete, separate quantities, allowing for flexible production runs and easier quality control adjustments. Continuous processing equipment operates non-stop, providing higher throughput and consistent product quality through steady-state production. Key differences include operational speed, scalability, and suitability for varying production volumes, with batch favored for customization and continuous for large-scale efficiency.

Advantages of Batch Processing Equipment

Batch processing equipment offers superior flexibility in handling multiple product variations, allowing manufacturers to switch formulations with ease and minimal downtime. It enables precise control over reaction times, temperatures, and ingredient ratios, ensuring consistent quality for small to medium production volumes. Cost efficiency is achieved by reducing waste and optimizing resource use during varied production runs, making it ideal for specialty or seasonal products.

Advantages of Continuous Processing Equipment

Continuous processing equipment offers significant advantages such as higher production efficiency and consistent product quality due to uninterrupted operation. It enables better scalability and reduced labor costs compared to batch processing. The equipment also minimizes downtime, leading to increased throughput and optimized resource utilization.

Applications Suited for Batch Processing Equipment

Batch processing equipment is ideal for small to medium-scale production runs, specialty chemicals, pharmaceuticals, and food products where flexibility in formulation and frequent changeovers are required. It suits applications demanding precise control over reaction times, temperature gradients, and ingredient mixing, such as in custom drug manufacturing and specialty chemical synthesis. Industries involving high product variability and quality assurance, like cosmetics and biotech, often rely on batch systems for tailored production.

Applications Suited for Continuous Processing Equipment

Continuous processing equipment excels in applications requiring high-volume, consistent production such as chemical manufacturing, pharmaceuticals, and food processing. Industries benefit from its ability to maintain steady-state operation, ensuring uniform product quality and minimizing downtime. This equipment is ideal for processes involving liquid mixing, fermentation, and chemical reactions that demand precise control and continuous input-output flow.

Cost Considerations: Batch vs Continuous Equipment

Batch processing equipment generally incurs higher per-unit operating costs due to frequent cleaning, setup, and changeover times, which reduce overall efficiency. Continuous processing equipment demands substantial initial capital investment but offers lower variable costs by operating non-stop, leading to economies of scale in large production volumes. Cost-effectiveness depends on production scale, with batch equipment favored for smaller, flexible runs and continuous equipment optimized for large, steady outputs.

Flexibility and Scalability in Batch vs Continuous Systems

Batch processing equipment offers high flexibility by allowing easy adjustment of product types and production volumes, ideal for customized or small-scale manufacturing. Continuous processing equipment excels in scalability, providing consistent, high-volume output with minimal downtime, making it suitable for large-scale industrial operations. Choosing between batch and continuous systems depends on production goals, with batch favored for versatility and continuous for efficiency.

Maintenance and Operational Efficiency Comparison

Batch processing equipment typically requires more frequent maintenance due to start-stop cycles causing increased wear on components, while continuous processing equipment benefits from steady-state operation that reduces mechanical stress and extends equipment lifespan. Operational efficiency in batch systems is often lower because of downtime associated with cleaning, changeovers, and setup between batches, whereas continuous processing enables higher throughput with minimal interruption. Predictive maintenance technologies integrated into continuous processing equipment further enhance operational efficiency by preventing unexpected failures and optimizing maintenance schedules.

Choosing the Right Equipment for Your Production Needs

Batch processing equipment offers flexibility for producing varied product quantities with easier quality control, ideal for small to medium production runs and custom formulations. Continuous processing equipment ensures high throughput and consistent product quality, best suited for large-scale, homogeneous production demands and minimizing downtime. Selecting the right equipment depends on factors like production volume, product complexity, budget constraints, and desired process efficiency.

Batch processing equipment vs continuous processing equipment Infographic

productdif.com

productdif.com