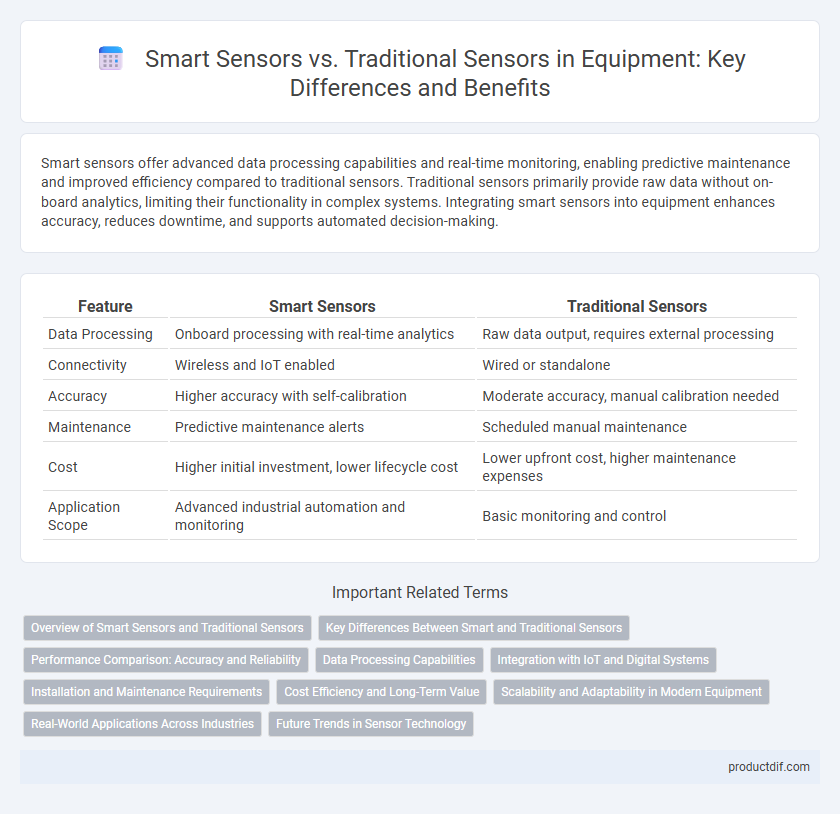

Smart sensors offer advanced data processing capabilities and real-time monitoring, enabling predictive maintenance and improved efficiency compared to traditional sensors. Traditional sensors primarily provide raw data without on-board analytics, limiting their functionality in complex systems. Integrating smart sensors into equipment enhances accuracy, reduces downtime, and supports automated decision-making.

Table of Comparison

| Feature | Smart Sensors | Traditional Sensors |

|---|---|---|

| Data Processing | Onboard processing with real-time analytics | Raw data output, requires external processing |

| Connectivity | Wireless and IoT enabled | Wired or standalone |

| Accuracy | Higher accuracy with self-calibration | Moderate accuracy, manual calibration needed |

| Maintenance | Predictive maintenance alerts | Scheduled manual maintenance |

| Cost | Higher initial investment, lower lifecycle cost | Lower upfront cost, higher maintenance expenses |

| Application Scope | Advanced industrial automation and monitoring | Basic monitoring and control |

Overview of Smart Sensors and Traditional Sensors

Smart sensors integrate microprocessors to analyze data internally, enabling real-time monitoring and decision-making without external processing. Traditional sensors primarily collect raw data, requiring external devices for interpretation, which can lead to slower response times. The advancement of smart sensor technology revolutionizes equipment efficiency by offering enhanced accuracy, self-calibration, and remote connectivity compared to conventional sensor systems.

Key Differences Between Smart and Traditional Sensors

Smart sensors integrate built-in microprocessors enabling real-time data processing and communication, whereas traditional sensors solely provide raw analog signals requiring external interpretation. Smart sensors enhance accuracy, offer self-diagnostics, and support wireless connectivity, unlike traditional sensors that generally rely on wired connections and manual calibration. The shift towards smart sensors drives improved efficiency, predictive maintenance, and seamless integration in automated systems.

Performance Comparison: Accuracy and Reliability

Smart sensors outperform traditional sensors in accuracy by integrating advanced algorithms and real-time data processing, which reduces errors caused by environmental noise and signal distortion. Their reliability is enhanced through self-diagnostic features and adaptive calibration, allowing consistent performance under varying conditions. Traditional sensors often lack these capabilities, resulting in less precise measurements and higher maintenance requirements.

Data Processing Capabilities

Smart sensors incorporate embedded microprocessors that enable real-time data processing, analysis, and decision-making at the source, significantly reducing latency and bandwidth requirements. Traditional sensors, in contrast, transmit raw data to external systems for processing, often causing delays and increasing the risk of data loss or corruption during transmission. The enhanced data processing capabilities of smart sensors facilitate more accurate monitoring, predictive maintenance, and adaptive control in complex equipment systems.

Integration with IoT and Digital Systems

Smart sensors offer seamless integration with IoT and digital systems by enabling real-time data collection, analysis, and remote monitoring through advanced communication protocols such as MQTT and Bluetooth Low Energy. Traditional sensors lack this connectivity, limiting their ability to provide continuous, automated data streams necessary for predictive maintenance and smart automation. The enhanced interoperability of smart sensors drives efficiency and accuracy in digital equipment management across industrial and consumer applications.

Installation and Maintenance Requirements

Smart sensors simplify installation with wireless connectivity and self-calibration features, reducing the need for extensive wiring and manual adjustments. Traditional sensors often require complex setup processes involving physical connections and frequent recalibration, increasing maintenance demands. The advanced diagnostics in smart sensors enable predictive maintenance, minimizing downtime compared to the reactive upkeep typical of traditional sensor systems.

Cost Efficiency and Long-Term Value

Smart sensors offer higher cost efficiency than traditional sensors by reducing maintenance expenses through real-time monitoring and predictive analytics. The long-term value of smart sensors is enhanced by their ability to provide accurate data for improved decision-making, leading to decreased downtime and optimized equipment performance. Traditional sensors often incur higher operational costs due to periodic manual checks and limited diagnostic capabilities.

Scalability and Adaptability in Modern Equipment

Smart sensors offer superior scalability and adaptability compared to traditional sensors, enabling seamless integration with modern equipment through wireless connectivity and advanced data processing. Traditional sensors often require extensive manual calibration and limited communication protocols, restricting their flexibility in dynamic environments. The enhanced scalability of smart sensors supports real-time monitoring and predictive maintenance, optimizing operational efficiency in complex industrial systems.

Real-World Applications Across Industries

Smart sensors revolutionize real-world applications across industries by integrating advanced data processing and connectivity, enabling precise monitoring in manufacturing, healthcare, and agriculture. Traditional sensors provide fundamental detection but lack real-time analytics and remote communication, limiting their efficiency in complex systems like autonomous vehicles and smart grids. Industries increasingly adopt smart sensors to enhance predictive maintenance, optimize resource management, and improve decision-making processes.

Future Trends in Sensor Technology

Smart sensors integrate AI and IoT connectivity, enabling real-time data processing and predictive maintenance, which significantly outperforms traditional sensors that solely provide raw data. Future trends emphasize miniaturization, enhanced energy efficiency through energy harvesting, and advanced materials like graphene to improve sensitivity and durability. These innovations will drive widespread adoption in industries such as manufacturing, healthcare, and autonomous vehicles, reshaping equipment monitoring and control systems.

Smart sensors vs Traditional sensors Infographic

productdif.com

productdif.com