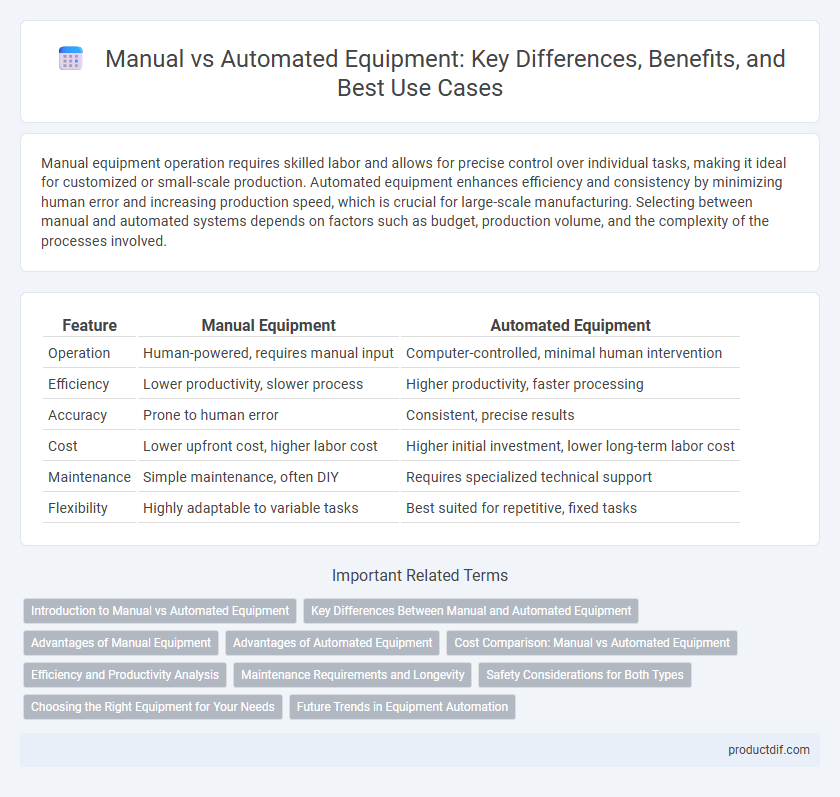

Manual equipment operation requires skilled labor and allows for precise control over individual tasks, making it ideal for customized or small-scale production. Automated equipment enhances efficiency and consistency by minimizing human error and increasing production speed, which is crucial for large-scale manufacturing. Selecting between manual and automated systems depends on factors such as budget, production volume, and the complexity of the processes involved.

Table of Comparison

| Feature | Manual Equipment | Automated Equipment |

|---|---|---|

| Operation | Human-powered, requires manual input | Computer-controlled, minimal human intervention |

| Efficiency | Lower productivity, slower process | Higher productivity, faster processing |

| Accuracy | Prone to human error | Consistent, precise results |

| Cost | Lower upfront cost, higher labor cost | Higher initial investment, lower long-term labor cost |

| Maintenance | Simple maintenance, often DIY | Requires specialized technical support |

| Flexibility | Highly adaptable to variable tasks | Best suited for repetitive, fixed tasks |

Introduction to Manual vs Automated Equipment

Manual equipment requires human operation and control, offering flexibility and precision for small-scale or custom tasks. Automated equipment uses programmed machinery and robotics to perform repetitive tasks efficiently, increasing productivity and reducing human error in large-scale production. Selecting between manual and automated equipment depends on factors like production volume, cost, and desired accuracy.

Key Differences Between Manual and Automated Equipment

Manual equipment relies on human operation, requiring physical skill and constant attention, while automated equipment uses programmed controls and sensors to perform tasks with minimal human intervention. Automated systems increase efficiency, reduce errors, and can operate continuously, contrasting with manual tools that are limited by human endurance and variability. Maintenance for manual devices is generally simpler, whereas automated equipment demands specialized knowledge for troubleshooting and upkeep.

Advantages of Manual Equipment

Manual equipment offers precise control and flexibility, allowing operators to adjust settings instantly based on real-time observations. It typically requires lower initial investment and maintenance costs compared to automated systems, making it ideal for small-scale operations or customized tasks. Manual tools also enhance skill development and operator engagement, fostering expertise and adaptability in various equipment applications.

Advantages of Automated Equipment

Automated equipment enhances operational efficiency by consistently performing repetitive tasks with high precision and speed, reducing human error and downtime. It enables real-time data collection and monitoring, facilitating predictive maintenance and improving overall productivity. The integration of automated systems also lowers labor costs and enhances workplace safety by minimizing direct human intervention in hazardous environments.

Cost Comparison: Manual vs Automated Equipment

Manual equipment generally incurs lower upfront costs but leads to higher long-term expenses due to increased labor and maintenance requirements. Automated equipment demands a significant initial investment, yet it reduces labor costs and enhances operational efficiency over time. Companies must evaluate total cost of ownership, including equipment price, labor savings, maintenance, and productivity gains, to determine the most cost-effective solution.

Efficiency and Productivity Analysis

Manual equipment operation typically results in slower production rates and increased variability in output quality due to human error. Automated systems enhance efficiency by ensuring consistent performance, reducing downtime, and enabling continuous operation with minimal supervision. Productivity analysis reveals that automated equipment significantly lowers labor costs and increases throughput, leading to higher overall operational effectiveness.

Maintenance Requirements and Longevity

Manual equipment typically requires more frequent maintenance due to increased wear from direct human operation, leading to shorter lifespan compared to automated systems. Automated equipment incorporates sensors and predictive maintenance technologies that minimize downtime and extend operational longevity by addressing issues before they escalate. Investing in automation can reduce maintenance costs while enhancing equipment reliability and durability.

Safety Considerations for Both Types

Manual equipment requires operators to remain vigilant and follow strict safety protocols to prevent accidental injuries, as human error is a primary risk factor. Automated equipment integrates sensors and emergency shutoff systems designed to minimize hazards and reduce workplace accidents, though malfunctions and maintenance lapses can still pose safety risks. Both types demand comprehensive training programs and regular safety audits to ensure safe operation and compliance with industry standards.

Choosing the Right Equipment for Your Needs

Selecting the right equipment depends on evaluating manual versus automated options based on operational efficiency, precision, and cost-effectiveness. Manual equipment offers greater control and flexibility for smaller-scale tasks, while automated machinery enhances productivity and consistency in high-volume environments. Consider the complexity of the task, budget constraints, and long-term maintenance when deciding which equipment best aligns with your operational requirements.

Future Trends in Equipment Automation

Future trends in equipment automation emphasize increased integration of artificial intelligence and machine learning to enhance predictive maintenance and operational efficiency. Advanced sensors and IoT connectivity enable real-time data collection, reducing downtime and improving decision-making accuracy. Robotics and autonomous systems are expanding in complex manufacturing processes, driving higher precision and cost-effectiveness.

Manual vs Automated Infographic

productdif.com

productdif.com