Hot stamping uses heat and pressure to transfer metallic or colored foil onto a surface, producing vibrant and durable designs ideal for pet equipment branding. Cold stamping, on the other hand, employs pressure without heat, offering a cost-effective and faster method but with less vivid results and reduced durability. Choosing between hot and cold stamping depends on the desired finish quality and budget for pet equipment customization.

Table of Comparison

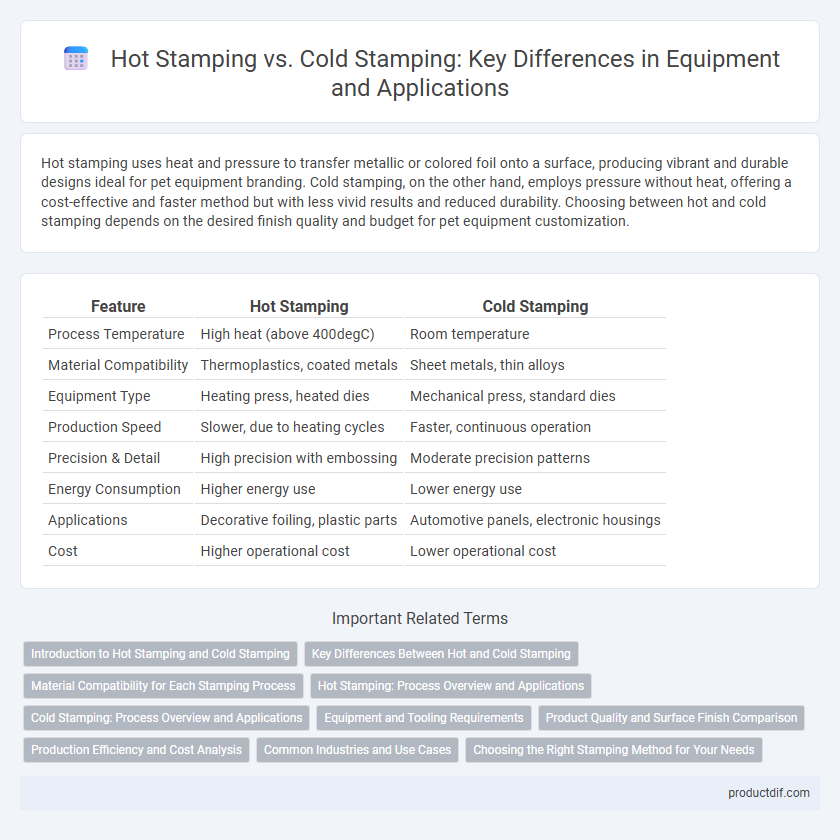

| Feature | Hot Stamping | Cold Stamping |

|---|---|---|

| Process Temperature | High heat (above 400degC) | Room temperature |

| Material Compatibility | Thermoplastics, coated metals | Sheet metals, thin alloys |

| Equipment Type | Heating press, heated dies | Mechanical press, standard dies |

| Production Speed | Slower, due to heating cycles | Faster, continuous operation |

| Precision & Detail | High precision with embossing | Moderate precision patterns |

| Energy Consumption | Higher energy use | Lower energy use |

| Applications | Decorative foiling, plastic parts | Automotive panels, electronic housings |

| Cost | Higher operational cost | Lower operational cost |

Introduction to Hot Stamping and Cold Stamping

Hot stamping uses heat and pressure to transfer foil or emboss designs onto materials like leather, plastics, and metals, creating durable and high-quality impressions ideal for branding and decoration. Cold stamping involves pressing a die onto a substrate without heat, suitable for thinner, heat-sensitive materials and applications requiring quick, cost-effective marking. Both methods enhance product aesthetics and functionality, with hot stamping offering vivid finishes and cold stamping providing precise, rapid imprints.

Key Differences Between Hot and Cold Stamping

Hot stamping uses heat and pressure to transfer foil or emboss designs onto surfaces, creating durable and visually striking finishes, while cold stamping relies on pressure only, without heat, making it suitable for delicate or heat-sensitive materials. The key differences include temperature application, material compatibility, and final appearance, with hot stamping offering richer colors and greater durability, whereas cold stamping is faster and more cost-effective for simple designs. Equipment for hot stamping typically requires heating elements and temperature controls, contrasting with the simpler mechanical setups used in cold stamping processes.

Material Compatibility for Each Stamping Process

Hot stamping is ideal for materials like high-strength steels and aluminum alloys that require enhanced formability and reduced spring-back during shaping. Cold stamping suits softer metals such as mild steel, copper, and brass, preserving material strength without heat-induced distortion. Selecting the right stamping process depends on the material's thermal sensitivity and desired mechanical properties.

Hot Stamping: Process Overview and Applications

Hot stamping involves heating a metal sheet to a high temperature before pressing it into a die, allowing for complex shapes with enhanced strength and surface finish. This process is widely used in automotive manufacturing for producing lightweight, durable components like structural reinforcements and body panels. Hot stamping improves mechanical properties through controlled cooling, making it ideal for applications requiring high tensile strength and precision.

Cold Stamping: Process Overview and Applications

Cold stamping involves shaping metal sheets at room temperature using high-pressure dies, which increases material strength through work hardening and maintains tight dimensional tolerances. This process is widely used in automotive manufacturing, electronics, and appliance production due to its ability to produce precise, consistent parts with minimal thermal distortion. Cold stamping enables high-speed production of intricate components such as brackets, connectors, and enclosures, making it ideal for large-volume industrial applications.

Equipment and Tooling Requirements

Hot stamping equipment requires specialized heating systems and temperature controls to maintain optimal foil adhesion, while cold stamping machinery relies on precise mechanical presses with high-tonnage capabilities for accurate embossing. Tooling for hot stamping demands heat-resistant materials such as brass or copper dies with polished surfaces to ensure consistent transfer of foil, whereas cold stamping tools utilize hardened steel dies designed for durability under repeated pressure without heat exposure. Both processes require customized setups to accommodate material types and production volumes, impacting initial equipment investment and maintenance schedules.

Product Quality and Surface Finish Comparison

Hot stamping typically produces superior product quality with enhanced mechanical properties due to the material's increased ductility during heat application, resulting in fewer cracks and defects. Cold stamping offers a smoother surface finish, preserving the original material texture with less oxidation, which is crucial for applications requiring high aesthetic standards. The choice between hot and cold stamping depends on the balance between the desired structural strength and surface appearance requirements.

Production Efficiency and Cost Analysis

Hot stamping enhances production efficiency by enabling faster cycle times and improved material formability, reducing waste and rework costs. Cold stamping typically involves lower initial equipment investment but may incur higher long-term costs due to slower processing speeds and increased tool wear. Evaluating total cost of ownership reveals hot stamping as more cost-effective for high-volume production runs requiring precision and durability.

Common Industries and Use Cases

Hot stamping is predominantly used in automotive, electronics, and packaging industries for decorative and protective finishes on metal and plastic components. Cold stamping finds extensive application in aerospace, appliance manufacturing, and electrical equipment production due to its precision and ability to retain material strength without heat alteration. Both processes serve crucial roles in mass production, with hot stamping excelling in surface enhancement and cold stamping favored for structural component fabrication.

Choosing the Right Stamping Method for Your Needs

Selecting the appropriate stamping method depends on factors such as material type, desired precision, and production volume. Hot stamping offers superior durability and aesthetic finishes for thermoplastics and metals, while cold stamping provides cost-effective solutions with faster cycle times for ductile materials. Evaluating these parameters ensures optimal equipment performance and product quality tailored to specific manufacturing requirements.

Hot stamping vs Cold stamping Infographic

productdif.com

productdif.com