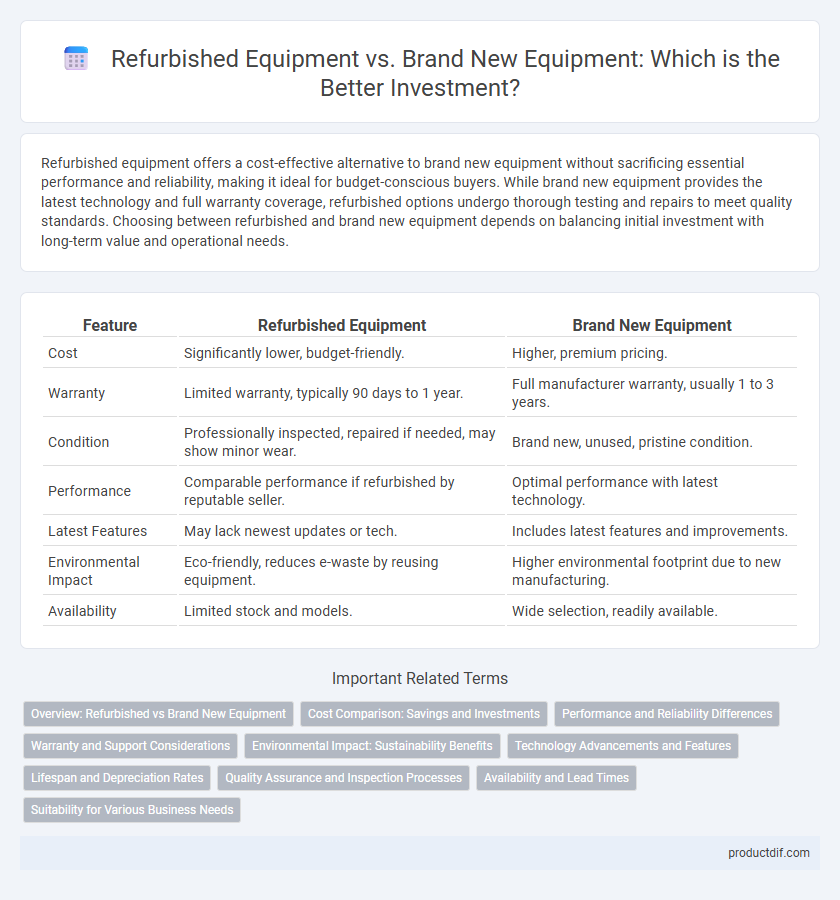

Refurbished equipment offers a cost-effective alternative to brand new equipment without sacrificing essential performance and reliability, making it ideal for budget-conscious buyers. While brand new equipment provides the latest technology and full warranty coverage, refurbished options undergo thorough testing and repairs to meet quality standards. Choosing between refurbished and brand new equipment depends on balancing initial investment with long-term value and operational needs.

Table of Comparison

| Feature | Refurbished Equipment | Brand New Equipment |

|---|---|---|

| Cost | Significantly lower, budget-friendly. | Higher, premium pricing. |

| Warranty | Limited warranty, typically 90 days to 1 year. | Full manufacturer warranty, usually 1 to 3 years. |

| Condition | Professionally inspected, repaired if needed, may show minor wear. | Brand new, unused, pristine condition. |

| Performance | Comparable performance if refurbished by reputable seller. | Optimal performance with latest technology. |

| Latest Features | May lack newest updates or tech. | Includes latest features and improvements. |

| Environmental Impact | Eco-friendly, reduces e-waste by reusing equipment. | Higher environmental footprint due to new manufacturing. |

| Availability | Limited stock and models. | Wide selection, readily available. |

Overview: Refurbished vs Brand New Equipment

Refurbished equipment undergoes thorough inspection and repairs to meet manufacturer standards, offering cost-effective alternatives with warranty coverage, ideal for budget-conscious buyers. Brand new equipment guarantees the latest technology, full manufacturer warranties, and the longest lifespan, suitable for operations requiring peak performance and reliability. Choosing between refurbished and new equipment depends on balancing initial investment against desired performance and risk tolerance.

Cost Comparison: Savings and Investments

Refurbished equipment offers significant cost savings, often priced 30-50% lower than brand new equipment, allowing businesses to maximize their budget without sacrificing quality. Investments in refurbished equipment can yield high returns by providing reliable performance and extending asset lifespan while reducing depreciation costs. Brand new equipment typically requires a larger upfront investment but may offer longer warranties and the latest technology innovations.

Performance and Reliability Differences

Refurbished equipment often undergoes thorough testing and repairs to meet manufacturer standards, ensuring comparable performance to brand new equipment in many cases. However, brand new equipment typically offers the latest technology and a full warranty, enhancing reliability and reducing the likelihood of malfunctions. Users prioritizing guaranteed uptime and cutting-edge features may prefer new, while refurbished options provide cost-effective solutions with acceptable performance for less critical applications.

Warranty and Support Considerations

Refurbished equipment often comes with a limited warranty period compared to brand new equipment, which typically includes full manufacturer warranties lasting one to three years. Support for refurbished products may be restricted to seller-provided services, while new equipment benefits from comprehensive manufacturer support, including software updates and technical assistance. Evaluating warranty terms and support options is crucial when deciding between refurbished and brand new equipment to ensure long-term reliability and service coverage.

Environmental Impact: Sustainability Benefits

Refurbished equipment significantly reduces electronic waste by extending the lifecycle of existing products, thereby minimizing landfill contributions and conserving raw materials. Using refurbished devices lowers carbon emissions associated with manufacturing new equipment, helping to reduce overall environmental footprints. Choosing refurbished over brand new supports circular economy principles, promoting resource efficiency and sustainable consumption.

Technology Advancements and Features

Refurbished equipment often incorporates previous technology standards and may lack the latest advancements found in brand new equipment, such as enhanced processing power, improved energy efficiency, and updated software compatibility. Brand new equipment benefits from cutting-edge features like advanced AI integration, faster connectivity options, and modern ergonomic designs that optimize performance and user experience. Choosing brand new technology ensures access to the most recent innovations and extended manufacturer warranties, while refurbished units provide cost savings with some trade-offs in features and future-proof capabilities.

Lifespan and Depreciation Rates

Refurbished equipment typically has a shorter remaining lifespan compared to brand new equipment due to prior usage and potential wear. Depreciation rates for refurbished equipment are generally steeper initially, but they tend to stabilize faster, resulting in lower long-term value loss. Brand new equipment offers maximum operational longevity and slower, more predictable depreciation, enhancing overall return on investment.

Quality Assurance and Inspection Processes

Refurbished equipment undergoes rigorous quality assurance and inspection processes, including thorough testing, repairs, and certifications to meet industry standards, ensuring dependable performance comparable to brand new equipment. Brand new equipment benefits from factory-calibrated components and standardized quality control protocols directly from manufacturers, minimizing defect rates and guaranteeing warranty coverage. Both options require systematic inspections, but refurbished equipment emphasizes restoration and validation to extend service life while maintaining operational reliability.

Availability and Lead Times

Refurbished equipment offers significantly shorter lead times due to immediate availability from existing stock, making it ideal for urgent project needs. Brand new equipment often involves longer lead times because of manufacturing schedules and shipping logistics, which can delay deployment. Manufacturers and suppliers frequently provide refurbished options with certified quality, ensuring reliable performance without the extended wait associated with new equipment orders.

Suitability for Various Business Needs

Refurbished equipment offers cost-effective solutions ideal for startups and small businesses with budget constraints, providing high functionality at reduced prices. Brand new equipment suits enterprises requiring the latest technology, warranty coverage, and maximum reliability for critical operations. Choosing between refurbished and new depends on factors like operational demands, financial resources, and expected equipment lifespan.

Refurbished equipment vs brand new equipment Infographic

productdif.com

productdif.com