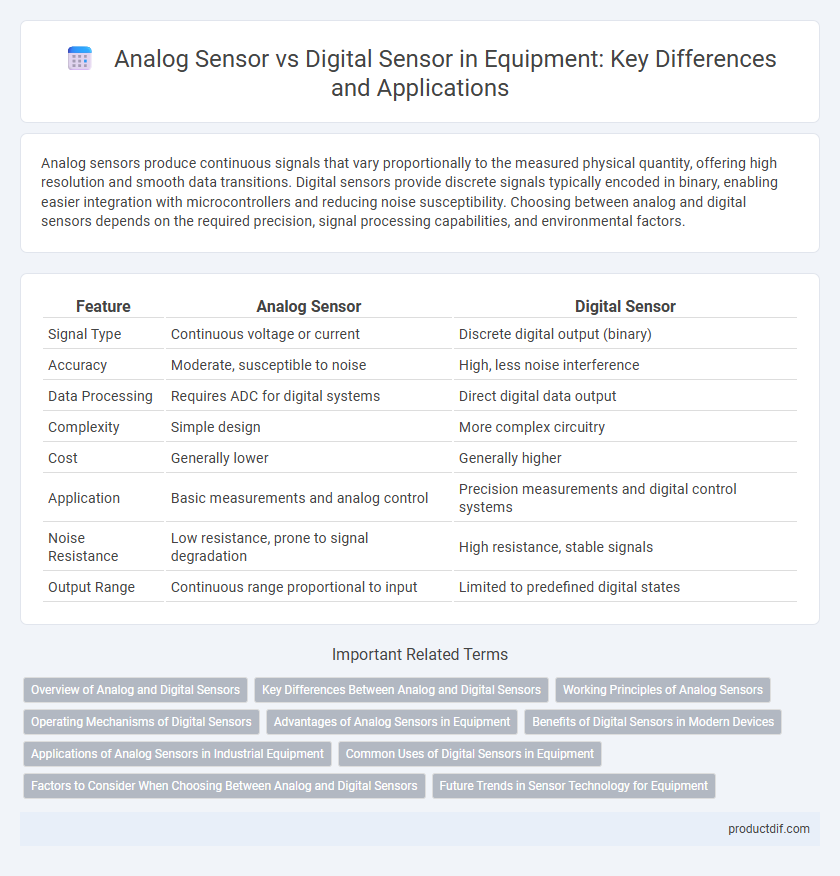

Analog sensors produce continuous signals that vary proportionally to the measured physical quantity, offering high resolution and smooth data transitions. Digital sensors provide discrete signals typically encoded in binary, enabling easier integration with microcontrollers and reducing noise susceptibility. Choosing between analog and digital sensors depends on the required precision, signal processing capabilities, and environmental factors.

Table of Comparison

| Feature | Analog Sensor | Digital Sensor |

|---|---|---|

| Signal Type | Continuous voltage or current | Discrete digital output (binary) |

| Accuracy | Moderate, susceptible to noise | High, less noise interference |

| Data Processing | Requires ADC for digital systems | Direct digital data output |

| Complexity | Simple design | More complex circuitry |

| Cost | Generally lower | Generally higher |

| Application | Basic measurements and analog control | Precision measurements and digital control systems |

| Noise Resistance | Low resistance, prone to signal degradation | High resistance, stable signals |

| Output Range | Continuous range proportional to input | Limited to predefined digital states |

Overview of Analog and Digital Sensors

Analog sensors continuously measure physical quantities and convert them into proportional electrical signals, offering smooth and precise data for applications requiring variable outputs. Digital sensors translate physical measurements into discrete binary signals, enhancing noise immunity and allowing direct interfacing with microcontrollers and digital systems. Both sensor types serve critical roles in equipment, with analog sensors favoring high-resolution monitoring and digital sensors excelling in robust, programmable environments.

Key Differences Between Analog and Digital Sensors

Analog sensors generate continuous signals that represent physical measurements with varying voltage or current levels, enabling precise detection of subtle changes. Digital sensors convert input into discrete binary signals, providing simplified, noise-immune data ideal for robust digital processing. Key differences include signal output type, accuracy in signal representation, and compatibility with digital systems.

Working Principles of Analog Sensors

Analog sensors operate by continuously converting physical parameters such as temperature, pressure, or light intensity into analog electrical signals, typically voltage or current, which vary proportionally to the measured quantity. These sensors rely on principles like resistance change in thermistors, voltage generation in piezoelectric sensors, or capacitance variation in capacitive sensors to produce a continuous output signal. The analog output requires conversion through an analog-to-digital converter (ADC) for digital systems to process and analyze the sensor data effectively.

Operating Mechanisms of Digital Sensors

Digital sensors operate by converting physical signals such as temperature, pressure, or light into discrete digital signals through an integrated analog-to-digital converter (ADC). These sensors utilize microprocessors to process and encode the sensor data into binary form, enabling precise and noise-resistant output suitable for digital systems. The operating mechanism enhances accuracy and allows seamless integration with modern digital equipment and control units.

Advantages of Analog Sensors in Equipment

Analog sensors provide continuous, real-time data output, enabling precise monitoring and control in equipment applications. They offer higher sensitivity and resolution for detecting subtle changes in physical parameters like temperature, pressure, and vibration. Their simple design and lower cost make them ideal for robust, reliable integration in industrial and automotive equipment systems.

Benefits of Digital Sensors in Modern Devices

Digital sensors provide higher accuracy and noise resistance compared to analog sensors, enhancing data reliability in modern devices. Their output is easily integrated with microcontrollers and digital systems, simplifying signal processing and reducing the need for complex analog-to-digital conversion. These sensors also support advanced features like self-calibration and diagnostic functions, improving overall device performance and maintenance efficiency.

Applications of Analog Sensors in Industrial Equipment

Analog sensors in industrial equipment excel at providing continuous real-time monitoring of variables such as temperature, pressure, and flow rate, crucial for precise process control. Their ability to capture subtle changes in physical parameters makes them ideal for applications like HVAC systems, robotic arms, and hydraulic machinery. Industries rely on analog sensors for their accuracy in detecting gradual variations, enabling predictive maintenance and reducing downtime.

Common Uses of Digital Sensors in Equipment

Digital sensors are extensively used in equipment for precise measurement and control applications, such as temperature monitoring, motion detection, and proximity sensing. They provide accurate, noise-resistant signals ideal for automation systems, robotics, and industrial machinery. Their integration with microcontrollers enhances data processing efficiency and real-time decision-making in advanced equipment.

Factors to Consider When Choosing Between Analog and Digital Sensors

Choosing between analog and digital sensors depends on factors such as required signal type, accuracy, and environmental conditions. Analog sensors provide continuous data suitable for monitoring gradual changes, while digital sensors offer discrete signals advantageous for noise resistance and ease of integration with microcontrollers. Consider signal processing complexity, power consumption, and the necessity for real-time data when selecting the appropriate sensor type.

Future Trends in Sensor Technology for Equipment

Future trends in sensor technology for equipment emphasize the integration of digital sensors due to their enhanced accuracy, ease of data processing, and compatibility with IoT systems, enabling real-time monitoring and predictive maintenance. Analog sensors continue to hold value in applications requiring high sensitivity and simplicity, but advancements in digital sensor miniaturization, energy efficiency, and wireless connectivity are driving widespread adoption in industrial and consumer equipment. Emerging innovations such as AI-powered sensor data analytics and hybrid sensor designs are set to transform equipment performance and operational efficiency.

Analog sensor vs digital sensor Infographic

productdif.com

productdif.com