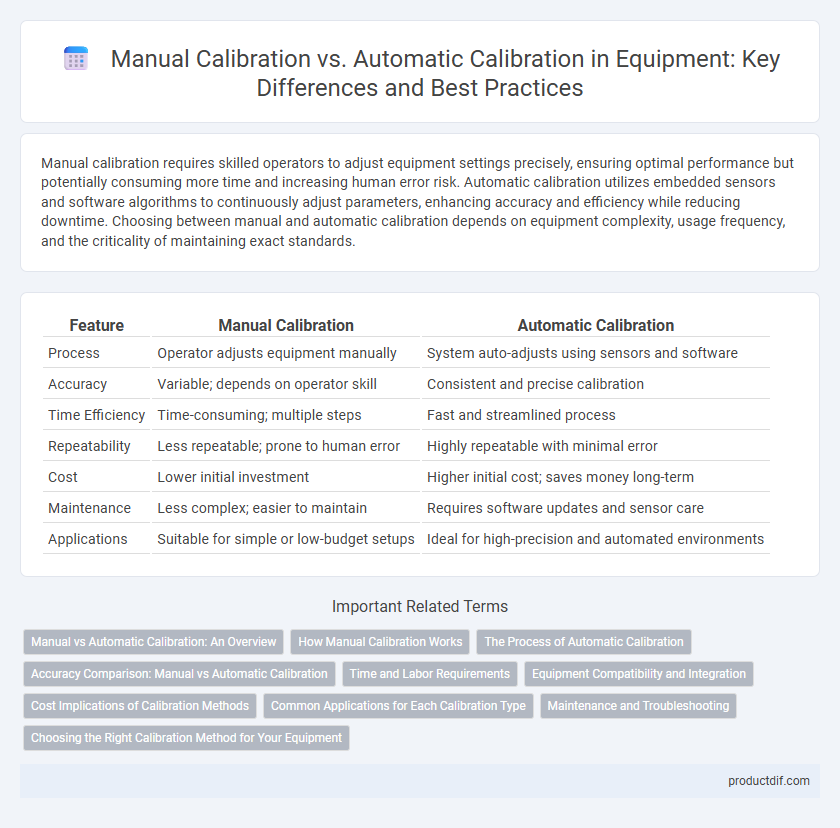

Manual calibration requires skilled operators to adjust equipment settings precisely, ensuring optimal performance but potentially consuming more time and increasing human error risk. Automatic calibration utilizes embedded sensors and software algorithms to continuously adjust parameters, enhancing accuracy and efficiency while reducing downtime. Choosing between manual and automatic calibration depends on equipment complexity, usage frequency, and the criticality of maintaining exact standards.

Table of Comparison

| Feature | Manual Calibration | Automatic Calibration |

|---|---|---|

| Process | Operator adjusts equipment manually | System auto-adjusts using sensors and software |

| Accuracy | Variable; depends on operator skill | Consistent and precise calibration |

| Time Efficiency | Time-consuming; multiple steps | Fast and streamlined process |

| Repeatability | Less repeatable; prone to human error | Highly repeatable with minimal error |

| Cost | Lower initial investment | Higher initial cost; saves money long-term |

| Maintenance | Less complex; easier to maintain | Requires software updates and sensor care |

| Applications | Suitable for simple or low-budget setups | Ideal for high-precision and automated environments |

Manual vs Automatic Calibration: An Overview

Manual calibration requires skilled technicians to adjust equipment settings based on reference standards, ensuring precise measurement through hands-on intervention. Automatic calibration utilizes integrated sensors and software algorithms to self-adjust equipment parameters, offering faster and more consistent results with minimal human input. Choosing between manual and automatic calibration depends on factors like equipment complexity, required accuracy, and operational efficiency.

How Manual Calibration Works

Manual calibration involves an operator adjusting equipment settings based on reference standards to ensure measurement accuracy. Technicians use calibrated tools such as multimeters or pressure gauges to compare and correct the device output against known values. This hands-on process requires precision and expertise to maintain equipment performance and compliance with industry standards.

The Process of Automatic Calibration

Automatic calibration utilizes sensors and embedded software algorithms to precisely adjust equipment settings without human intervention. The process involves real-time data collection, analysis, and dynamic tuning to ensure consistent accuracy and optimal performance. This method reduces errors, saves time, and enhances reliability compared to manual calibration techniques.

Accuracy Comparison: Manual vs Automatic Calibration

Automatic calibration generally provides higher accuracy by minimizing human error and ensuring consistent adjustments based on precise sensor data. Manual calibration relies on operator skill and is prone to variability, which can lead to less reliable measurement results. Equipment using automatic calibration benefits from repeatable precision essential for industries demanding stringent compliance with quality standards.

Time and Labor Requirements

Manual calibration demands significant time and skilled labor due to hands-on adjustments and detailed measurements, often causing operational delays. Automatic calibration significantly reduces time requirements by using embedded sensors and software algorithms to perform precise adjustments with minimal human intervention. This efficiency shift lowers overall labor costs and improves equipment uptime, enhancing productivity in industrial settings.

Equipment Compatibility and Integration

Manual calibration requires equipment operators to adjust settings based on specific device parameters, which can limit compatibility with newer or more complex machinery. Automatic calibration systems offer enhanced integration capabilities, utilizing software algorithms and sensors to seamlessly adjust across a broader range of equipment types. This interoperability reduces downtime and ensures consistent precision in multi-device environments, making automatic calibration preferable for modern, interconnected setups.

Cost Implications of Calibration Methods

Manual calibration typically incurs higher labor costs due to the need for specialized technicians and longer calibration times, increasing overall operational expenses. Automatic calibration reduces human intervention, which lowers labor costs and minimizes downtime, leading to significant savings in repetitive calibration cycles. However, initial investment in automatic calibration equipment may be substantial, but the long-term cost benefits often outweigh these upfront expenses.

Common Applications for Each Calibration Type

Manual calibration is frequently used in laboratory settings and industries requiring precise, hands-on adjustments, such as pharmaceuticals and research facilities, where expert technicians ensure equipment accuracy. Automatic calibration is prevalent in manufacturing plants and quality control processes, benefiting high-volume production lines needing rapid, consistent, and reliable calibration with minimal human intervention. Both calibration types optimize equipment performance, with manual calibration excelling in intricate, low-volume tasks and automatic calibration enhancing efficiency in repetitive, large-scale operations.

Maintenance and Troubleshooting

Manual calibration requires skilled technicians to adjust equipment settings precisely, ensuring optimal performance but often increasing downtime and maintenance efforts. Automatic calibration reduces human error by using sensors and software algorithms to continuously monitor and adjust parameters, streamlining troubleshooting and minimizing equipment failures. Effective maintenance strategies combine both methods to balance accuracy, efficiency, and operational reliability.

Choosing the Right Calibration Method for Your Equipment

Manual calibration requires skilled technicians to adjust equipment settings precisely, making it suitable for specialized or older devices without built-in calibration capabilities. Automatic calibration uses embedded sensors and software algorithms to ensure rapid, consistent, and repeatable adjustments, ideal for high-volume or complex equipment requiring frequent calibration. Selecting the right calibration method depends on equipment type, accuracy requirements, operational efficiency, and cost considerations.

Manual calibration vs Automatic calibration Infographic

productdif.com

productdif.com