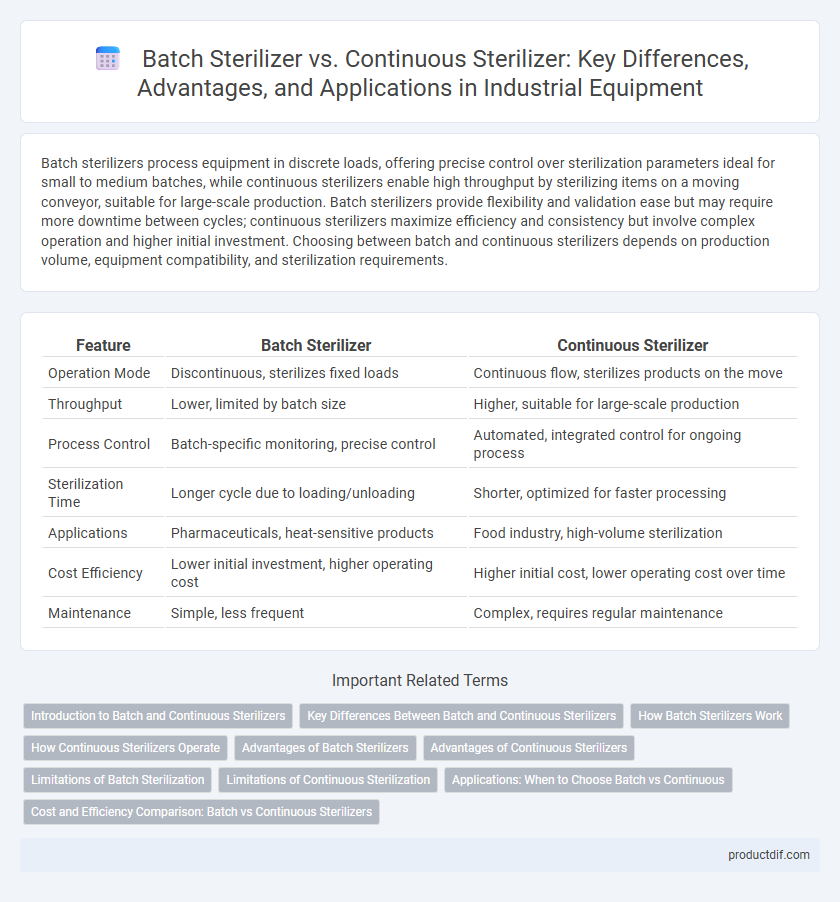

Batch sterilizers process equipment in discrete loads, offering precise control over sterilization parameters ideal for small to medium batches, while continuous sterilizers enable high throughput by sterilizing items on a moving conveyor, suitable for large-scale production. Batch sterilizers provide flexibility and validation ease but may require more downtime between cycles; continuous sterilizers maximize efficiency and consistency but involve complex operation and higher initial investment. Choosing between batch and continuous sterilizers depends on production volume, equipment compatibility, and sterilization requirements.

Table of Comparison

| Feature | Batch Sterilizer | Continuous Sterilizer |

|---|---|---|

| Operation Mode | Discontinuous, sterilizes fixed loads | Continuous flow, sterilizes products on the move |

| Throughput | Lower, limited by batch size | Higher, suitable for large-scale production |

| Process Control | Batch-specific monitoring, precise control | Automated, integrated control for ongoing process |

| Sterilization Time | Longer cycle due to loading/unloading | Shorter, optimized for faster processing |

| Applications | Pharmaceuticals, heat-sensitive products | Food industry, high-volume sterilization |

| Cost Efficiency | Lower initial investment, higher operating cost | Higher initial cost, lower operating cost over time |

| Maintenance | Simple, less frequent | Complex, requires regular maintenance |

Introduction to Batch and Continuous Sterilizers

Batch sterilizers process discrete loads in sealed chambers, ensuring thorough sterilization for each individual batch, commonly used in pharmaceutical and food industries where product variability is high. Continuous sterilizers enable nonstop processing by moving products through sterilization zones, maximizing efficiency and throughput ideal for large-scale manufacturing with consistent product types. The choice between batch and continuous sterilizers depends on factors like production volume, product sensitivity, and process control requirements.

Key Differences Between Batch and Continuous Sterilizers

Batch sterilizers process a fixed volume of materials in individual cycles, ensuring precise control over sterilization parameters such as temperature, time, and pressure for each batch. Continuous sterilizers operate with a constant flow, suitable for large-scale production, providing rapid sterilization by maintaining steady thermal conditions as materials move through the system. The key differences lie in operational mode, throughput capacity, and automation level, with batch sterilizers favoring flexibility and quality control, while continuous sterilizers emphasize efficiency and high-volume processing.

How Batch Sterilizers Work

Batch sterilizers operate by processing a fixed quantity of equipment or materials in a sealed chamber where steam or other sterilizing agents are introduced under controlled temperature and pressure conditions to eliminate microorganisms. The sterilization cycle includes stages such as heating, sterilizing, and cooling, ensuring uniform exposure throughout the batch. This method is ideal for small to medium-scale operations requiring high sterility assurance with precise control over each sterilization run.

How Continuous Sterilizers Operate

Continuous sterilizers operate by continuously passing products through a heated sterilizing zone at controlled temperatures and pressures, ensuring rapid and uniform microbial inactivation. These systems utilize conveyor belts or tubular heat exchangers to maintain constant product flow, enabling higher throughput compared to batch sterilizers. Temperature sensors and automated controls monitor and adjust sterilization parameters in real-time, optimizing process efficiency and product quality.

Advantages of Batch Sterilizers

Batch sterilizers offer precise control over sterilization parameters, ensuring consistent and reliable microbial inactivation for varied product types. Their flexibility accommodates small to medium production volumes, reducing cross-contamination risks through isolated sterilization cycles. Maintenance and validation processes are simpler compared to continuous sterilizers, leading to lower operational downtime and increased adaptability in pharmaceutical and food processing industries.

Advantages of Continuous Sterilizers

Continuous sterilizers offer superior efficiency by enabling uninterrupted processing of large volumes, significantly reducing cycle times compared to batch sterilizers. They provide consistent sterilization parameters ensuring uniform product quality and enhanced throughput. Integration with automated systems minimizes human intervention, resulting in lower labor costs and increased operational safety.

Limitations of Batch Sterilization

Batch sterilizers face limitations such as longer processing times due to the need to load and unload equipment between cycles, reducing overall throughput. Temperature and steam distribution inconsistencies can occur, leading to potential sterilization variability and risk of product contamination. These factors make batch sterilization less suitable for high-volume production compared to continuous sterilizers.

Limitations of Continuous Sterilization

Continuous sterilizers face limitations such as inability to handle large, irregularly shaped batches efficiently, leading to inconsistent sterilization. They require precise control of parameters like temperature and conveyor speed to ensure uniform exposure, which can be challenging in industrial settings. Moreover, continuous systems offer less flexibility for varied load sizes compared to batch sterilizers.

Applications: When to Choose Batch vs Continuous

Batch sterilizers are ideal for small to medium-sized production runs where flexibility and precise control over sterilization cycles are required, commonly used in pharmaceutical, biotechnology, and food industries for sensitive or varied products. Continuous sterilizers suit high-volume manufacturing environments, such as large-scale food processing and beverage production, where consistent throughput and efficiency are critical. Selecting between batch and continuous sterilizers depends on production scale, product sensitivity, and the need for process customization or automation.

Cost and Efficiency Comparison: Batch vs Continuous Sterilizers

Batch sterilizers generally incur higher operational costs due to longer cycle times and manual loading, impacting overall throughput efficiency. Continuous sterilizers optimize cost-efficiency by enabling nonstop processing with automated material flow, significantly increasing sterilization capacity and reducing labor expenses. Investment in continuous sterilization technology often yields faster return on investment through enhanced productivity and reduced per-unit sterilization costs.

Batch sterilizer vs Continuous sterilizer Infographic

productdif.com

productdif.com