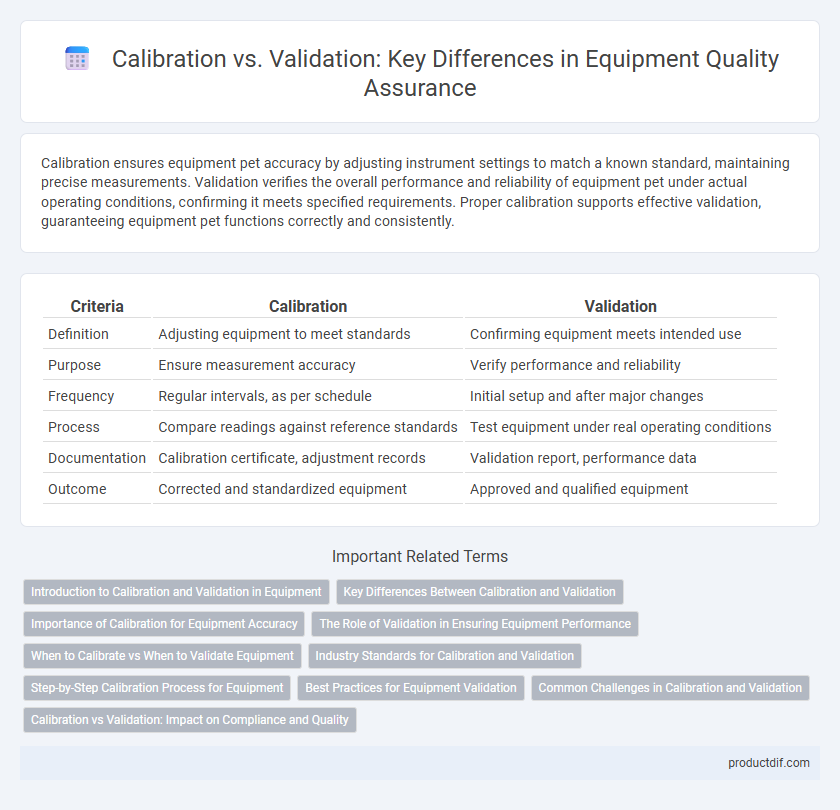

Calibration ensures equipment pet accuracy by adjusting instrument settings to match a known standard, maintaining precise measurements. Validation verifies the overall performance and reliability of equipment pet under actual operating conditions, confirming it meets specified requirements. Proper calibration supports effective validation, guaranteeing equipment pet functions correctly and consistently.

Table of Comparison

| Criteria | Calibration | Validation |

|---|---|---|

| Definition | Adjusting equipment to meet standards | Confirming equipment meets intended use |

| Purpose | Ensure measurement accuracy | Verify performance and reliability |

| Frequency | Regular intervals, as per schedule | Initial setup and after major changes |

| Process | Compare readings against reference standards | Test equipment under real operating conditions |

| Documentation | Calibration certificate, adjustment records | Validation report, performance data |

| Outcome | Corrected and standardized equipment | Approved and qualified equipment |

Introduction to Calibration and Validation in Equipment

Calibration ensures equipment accuracy by comparing measurements against standardized references to maintain consistent performance and comply with industry standards. Validation confirms that equipment operates within specified parameters and meets intended requirements for reliable, quality results. Both processes are critical in regulated environments such as pharmaceuticals, manufacturing, and laboratory settings for maintaining equipment integrity.

Key Differences Between Calibration and Validation

Calibration ensures measurement instruments produce accurate and precise readings by comparing them against known standards. Validation confirms that a process, system, or equipment consistently meets predetermined specifications and intended use in real operating conditions. While calibration focuses on the accuracy of instruments, validation assesses the overall suitability and reliability of the equipment or process in its actual application.

Importance of Calibration for Equipment Accuracy

Calibration ensures equipment accuracy by comparing measurements against known standards, minimizing errors and maintaining precision in data collection. Regular calibration is crucial for reliable performance, compliance with industry regulations, and extending the lifespan of measurement tools. Properly calibrated equipment reduces downtime and enhances overall operational efficiency in various industries.

The Role of Validation in Ensuring Equipment Performance

Validation in equipment management confirms that instruments consistently perform according to predetermined specifications under real-world conditions. It ensures accuracy, reliability, and compliance with industry standards by thoroughly testing equipment functionality and operational limits. This process is critical for maintaining quality control and minimizing risks in manufacturing, pharmaceutical, and laboratory environments.

When to Calibrate vs When to Validate Equipment

Calibrate equipment when precise measurement accuracy is required to ensure consistent performance and compliance with industry standards. Validate equipment during initial installation, after major repairs, or before critical production runs to confirm it operates as intended within specified parameters. Regular calibration maintains accuracy over time, while validation verifies overall functionality and suitability for its intended use.

Industry Standards for Calibration and Validation

Industry standards for calibration ensure equipment accuracy by adhering to protocols such as ISO/IEC 17025 for testing and calibration laboratories, establishing traceable measurements to national and international references. Validation standards, including ISO 9001 and GAMP 5, focus on confirming that equipment consistently produces results meeting predetermined specifications throughout its operational life. Compliance with these standards is critical for quality control, regulatory acceptance, and maintaining the integrity of measurement and production processes in industries like pharmaceuticals and manufacturing.

Step-by-Step Calibration Process for Equipment

The step-by-step calibration process for equipment begins with identifying the calibration standards and reference instruments that meet traceability requirements. Next, measure the equipment's output against these standards under controlled conditions to detect deviations or errors. Finalize by documenting all findings, adjusting the equipment as necessary, and re-verifying accuracy to ensure compliance with industry regulations and maintain optimal performance.

Best Practices for Equipment Validation

Effective equipment validation requires systematic calibration to ensure measurement accuracy and traceability to national standards. Regular calibration intervals, documented procedures, and qualified personnel are essential best practices to maintain equipment reliability. Validation extends beyond calibration by incorporating functional testing, performance qualification, and continuous monitoring to confirm equipment operates within specified parameters.

Common Challenges in Calibration and Validation

Calibration and validation both face challenges such as maintaining accuracy across varying environmental conditions and equipment wear over time. Ensuring consistent traceability to national or international standards is difficult due to discrepancies in reference materials and methods. Frequent recalibration and revalidation are necessary to address drift and guarantee compliant, reliable measurement results.

Calibration vs Validation: Impact on Compliance and Quality

Calibration ensures measurement accuracy by adjusting equipment to meet predefined standards, directly impacting compliance with regulatory requirements. Validation verifies that equipment consistently produces reliable results under actual operating conditions, crucial for maintaining product quality and process integrity. Effective calibration and validation together uphold both compliance and quality management systems, minimizing risk of non-conformance.

Calibration vs Validation Infographic

productdif.com

productdif.com