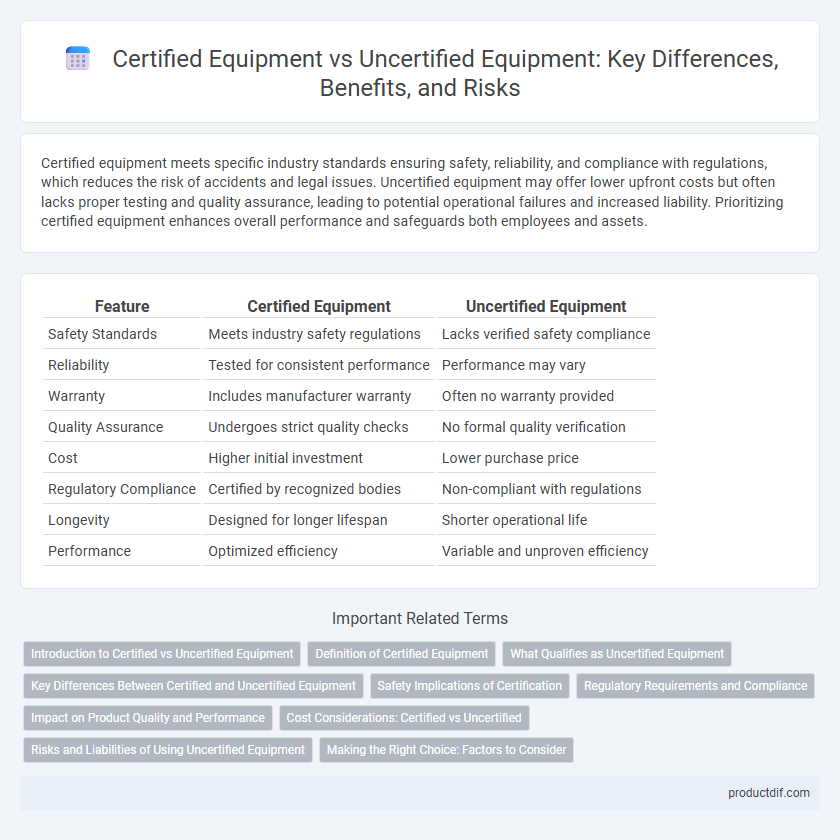

Certified equipment meets specific industry standards ensuring safety, reliability, and compliance with regulations, which reduces the risk of accidents and legal issues. Uncertified equipment may offer lower upfront costs but often lacks proper testing and quality assurance, leading to potential operational failures and increased liability. Prioritizing certified equipment enhances overall performance and safeguards both employees and assets.

Table of Comparison

| Feature | Certified Equipment | Uncertified Equipment |

|---|---|---|

| Safety Standards | Meets industry safety regulations | Lacks verified safety compliance |

| Reliability | Tested for consistent performance | Performance may vary |

| Warranty | Includes manufacturer warranty | Often no warranty provided |

| Quality Assurance | Undergoes strict quality checks | No formal quality verification |

| Cost | Higher initial investment | Lower purchase price |

| Regulatory Compliance | Certified by recognized bodies | Non-compliant with regulations |

| Longevity | Designed for longer lifespan | Shorter operational life |

| Performance | Optimized efficiency | Variable and unproven efficiency |

Introduction to Certified vs Uncertified Equipment

Certified equipment meets stringent industry standards and regulatory requirements, ensuring safety, reliability, and performance consistency. Uncertified equipment lacks official validation, which may lead to increased risks, non-compliance, and potential operational failures. Selecting certified equipment reduces liability and supports adherence to quality and safety protocols essential in professional and industrial environments.

Definition of Certified Equipment

Certified equipment refers to machinery or tools that have been evaluated and approved by recognized safety and quality standards organizations, ensuring compliance with specific regulatory requirements. This certification guarantees that the equipment meets established performance, safety, and reliability criteria, reducing risks during operation. In contrast, uncertified equipment lacks formal validation, potentially posing hazards and liability concerns in industrial and commercial applications.

What Qualifies as Uncertified Equipment

Uncertified equipment refers to devices or machinery that have not undergone official testing or validation by recognized certification bodies such as UL, CE, or ISO. This equipment often lacks documentation verifying compliance with industry standards, safety regulations, or performance criteria, increasing risks during operation. Using uncertified equipment can lead to potential hazards, operational failures, and legal liabilities due to its unverified quality and safety assurances.

Key Differences Between Certified and Uncertified Equipment

Certified equipment undergoes rigorous testing and meets established industry standards for safety, performance, and reliability, ensuring compliance with regulatory requirements. Uncertified equipment lacks formal validation, which increases risks related to safety failures, reduced operational efficiency, and potential legal liabilities. The primary distinctions lie in quality assurance, risk mitigation, and adherence to compliance protocols that certified equipment guarantees.

Safety Implications of Certification

Certified equipment undergoes rigorous testing and meets established safety standards, significantly reducing risks of malfunction and accidents. Uncertified equipment lacks verified compliance, increasing the likelihood of hazards such as electrical failures, structural weaknesses, or operational errors. Adhering to certified equipment protocols ensures enhanced reliability, worker protection, and regulatory compliance across industrial and commercial environments.

Regulatory Requirements and Compliance

Certified equipment complies with established regulatory requirements set by recognized standards organizations, ensuring safety, reliability, and quality in operational environments. Uncertified equipment lacks formal validation and may fail to meet mandatory compliance criteria, increasing the risk of legal penalties, equipment malfunctions, and safety hazards. Adherence to certification protocols is essential for regulatory compliance, risk management, and maintaining operational integrity across industries.

Impact on Product Quality and Performance

Certified equipment undergoes rigorous testing and compliance checks to ensure it meets industry standards, directly enhancing product quality and operational performance. Uncertified equipment often lacks these validations, increasing the risk of defects, inconsistencies, and reduced efficiency in production processes. Using certified equipment minimizes downtime and maintenance costs by guaranteeing reliability and adherence to safety regulations.

Cost Considerations: Certified vs Uncertified

Certified equipment typically involves higher upfront costs due to rigorous testing and compliance with industry standards, ensuring reliability, safety, and warranty benefits. Uncertified equipment may present lower initial expenses but often results in increased long-term costs from repairs, downtime, and potential regulatory fines. Evaluating total cost of ownership highlights that certified options offer better value through durability, reduced risks, and alignment with compliance requirements.

Risks and Liabilities of Using Uncertified Equipment

Using uncertified equipment significantly increases risks such as malfunction, safety hazards, and potential damage to property or personnel. Liability issues arise because uncertified equipment often fails to meet industry standards, exposing companies to legal penalties, insurance claim denials, and costly lawsuits. Certified equipment undergoes rigorous testing and compliance checks, ensuring reliability and reducing financial and operational risks.

Making the Right Choice: Factors to Consider

Choosing certified equipment ensures compliance with industry standards, safety regulations, and quality benchmarks, reducing risks of malfunction and liability. Uncertified equipment may offer lower initial costs but often lacks verified performance and reliability, potentially leading to higher long-term expenses and safety hazards. Key factors to consider include certification status, warranty coverage, manufacturer reputation, and alignment with specific operational requirements.

Certified equipment vs uncertified equipment Infographic

productdif.com

productdif.com