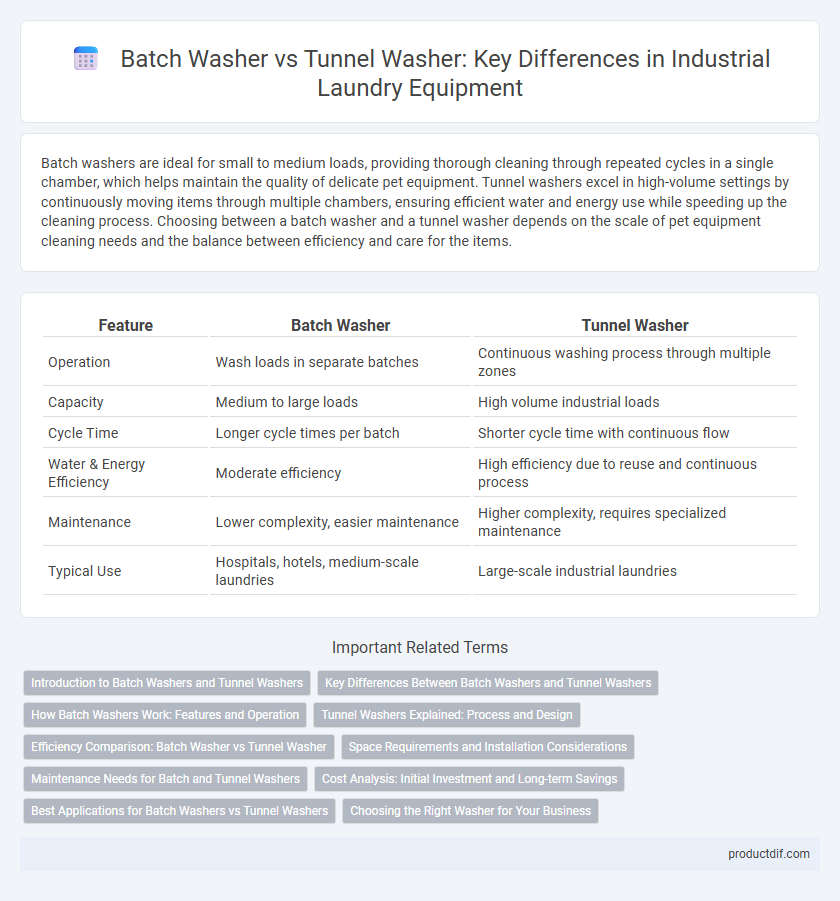

Batch washers are ideal for small to medium loads, providing thorough cleaning through repeated cycles in a single chamber, which helps maintain the quality of delicate pet equipment. Tunnel washers excel in high-volume settings by continuously moving items through multiple chambers, ensuring efficient water and energy use while speeding up the cleaning process. Choosing between a batch washer and a tunnel washer depends on the scale of pet equipment cleaning needs and the balance between efficiency and care for the items.

Table of Comparison

| Feature | Batch Washer | Tunnel Washer |

|---|---|---|

| Operation | Wash loads in separate batches | Continuous washing process through multiple zones |

| Capacity | Medium to large loads | High volume industrial loads |

| Cycle Time | Longer cycle times per batch | Shorter cycle time with continuous flow |

| Water & Energy Efficiency | Moderate efficiency | High efficiency due to reuse and continuous process |

| Maintenance | Lower complexity, easier maintenance | Higher complexity, requires specialized maintenance |

| Typical Use | Hospitals, hotels, medium-scale laundries | Large-scale industrial laundries |

Introduction to Batch Washers and Tunnel Washers

Batch washers operate by processing loads in discrete batches, allowing for precise control over washing parameters and customization for different fabric types. Tunnel washers utilize a continuous flow system where garments move through multiple compartments with varying wash cycles, enhancing efficiency for large-scale laundry operations. Choosing between batch and tunnel washers depends on factors such as laundry volume, fabric sensitivity, and throughput requirements.

Key Differences Between Batch Washers and Tunnel Washers

Batch washers handle loads in discrete cycles, making them ideal for smaller volumes and delicate fabrics requiring customized wash settings, while tunnel washers operate continuously, processing large volumes efficiently with consistent water and chemical usage. Batch washers offer greater flexibility and lower initial investment, whereas tunnel washers excel in high-capacity environments such as hospitals and large laundries due to their throughput and energy efficiency. Key differences include operational mode, capacity, water consumption, and suitability for different textile types and washing demands.

How Batch Washers Work: Features and Operation

Batch washers operate by processing laundry in discrete loads within a single drum, allowing precise control over wash cycles and chemical dosing. These machines use a series of agitation, soaking, and rinsing phases tailored to each batch, optimizing cleaning efficiency for varied fabric types. Their modular design supports flexible load sizes, energy-efficient water usage, and easy maintenance compared to continuous tunnel washers.

Tunnel Washers Explained: Process and Design

Tunnel washers utilize a continuous flow design where laundry moves through multiple compartments, each performing a specific washing stage such as washing, rinsing, and extraction, optimizing water and energy efficiency. Their modular construction allows for high-capacity processing, making them ideal for large-scale industrial laundry operations requiring consistent, scalable cleaning performance. Advanced tunnel washers incorporate precise chemical dosing and automated controls to enhance fabric care while maintaining rapid throughput and operational cost savings.

Efficiency Comparison: Batch Washer vs Tunnel Washer

Batch washers provide flexibility for varying load sizes but operate with longer cycle times, resulting in lower throughput and energy efficiency compared to tunnel washers. Tunnel washers use continuous operation and counter-current water flow, maximizing water and energy savings while handling large volumes with minimal labor input. Industrial laundry facilities benefit from tunnel washers due to higher productivity and reduced operational costs per kilogram of textiles cleaned.

Space Requirements and Installation Considerations

Batch washers require less floor space compared to tunnel washers, making them ideal for facilities with limited area. Installation of batch washers is relatively straightforward and quicker due to their compact design and fewer utility connections. Tunnel washers demand extensive space and complex installation processes, including specialized infrastructure for water, electrical, and drainage systems to accommodate their continuous operation.

Maintenance Needs for Batch and Tunnel Washers

Batch washers require more frequent maintenance due to their complex mechanical parts and manual loading process, increasing downtime for routine inspections and repairs. Tunnel washers, designed for continuous operation, have fewer moving components exposed to wear and benefit from automated cleaning cycles, reducing the intensity of maintenance tasks. Both systems demand regular monitoring of pumps, belts, and sensors, but tunnel washers generally offer lower overall maintenance costs and higher operational efficiency.

Cost Analysis: Initial Investment and Long-term Savings

Batch washers generally require a lower initial investment due to simpler design and smaller capacity, making them suitable for smaller operations. Tunnel washers involve higher upfront costs driven by advanced automation and greater throughput but deliver significant long-term savings through reduced water, energy consumption, and labor costs. Evaluating total cost of ownership reveals tunnel washers optimize operational efficiency and yield better ROI in high-volume laundry environments.

Best Applications for Batch Washers vs Tunnel Washers

Batch washers excel in applications requiring smaller, mixed-load laundry processing with high flexibility and precise control over wash cycles, making them ideal for hospitals, hotels, and small to medium-sized laundries. Tunnel washers are best suited for large-scale operations demanding high throughput and continuous wash processes, such as industrial laundries and large textile processing plants. Selection depends on volume, fabric type, and operational efficiency requirements, optimizing water and energy usage in each scenario.

Choosing the Right Washer for Your Business

Choosing the right washer for your business depends on laundry volume and efficiency needs; batch washers are ideal for smaller loads with flexible wash cycles, offering precise control for delicate fabrics. Tunnel washers are designed for high-volume operations, providing continuous, automated washing that maximizes throughput and reduces labor costs. Evaluating daily laundry capacity, fabric types, and operational budget ensures selection of equipment that optimizes productivity and energy consumption.

Batch washer vs Tunnel washer Infographic

productdif.com

productdif.com