Ultrasonic welding uses high-frequency mechanical vibrations to generate heat and join materials, making it ideal for plastics and thin metals with minimal thermal distortion. Laser welding employs a concentrated beam of light to achieve precise, deep penetration welds, suitable for thicker metals and complex geometries. Both methods offer fast, clean joins but differ significantly in equipment cost, material compatibility, and application precision.

Table of Comparison

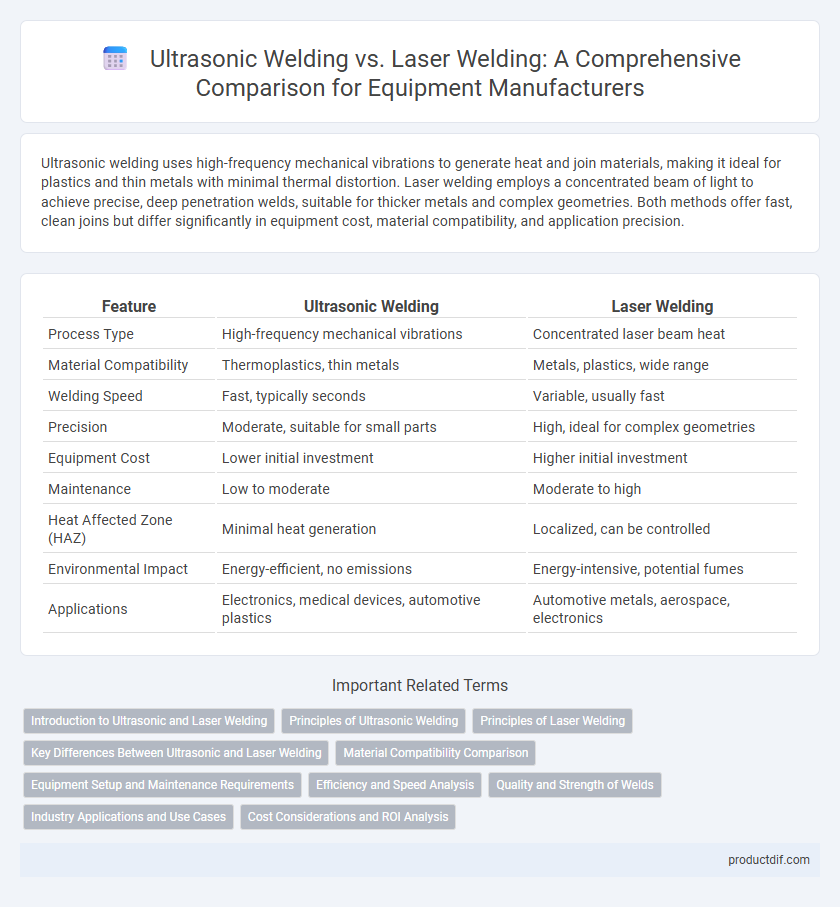

| Feature | Ultrasonic Welding | Laser Welding |

|---|---|---|

| Process Type | High-frequency mechanical vibrations | Concentrated laser beam heat |

| Material Compatibility | Thermoplastics, thin metals | Metals, plastics, wide range |

| Welding Speed | Fast, typically seconds | Variable, usually fast |

| Precision | Moderate, suitable for small parts | High, ideal for complex geometries |

| Equipment Cost | Lower initial investment | Higher initial investment |

| Maintenance | Low to moderate | Moderate to high |

| Heat Affected Zone (HAZ) | Minimal heat generation | Localized, can be controlled |

| Environmental Impact | Energy-efficient, no emissions | Energy-intensive, potential fumes |

| Applications | Electronics, medical devices, automotive plastics | Automotive metals, aerospace, electronics |

Introduction to Ultrasonic and Laser Welding

Ultrasonic welding uses high-frequency mechanical vibrations to create a solid-state bond between materials, ideal for polymers and delicate components. Laser welding employs a concentrated laser beam to melt and fuse materials with high precision and minimal heat-affected zones, suitable for metals and complex assemblies. Both technologies offer distinct advantages in manufacturing depending on material type, joint design, and production speed requirements.

Principles of Ultrasonic Welding

Ultrasonic welding joins materials through high-frequency ultrasonic vibrations applied under pressure, causing intermolecular friction and localized melting at the interface. This solid-state process requires no external heat source, making it ideal for thermoplastics and delicate components requiring precise, clean bonds. Ultrasonic wedge and horn shapes optimize energy delivery, ensuring efficient bonding without damage to parts.

Principles of Laser Welding

Laser welding relies on a concentrated laser beam to melt and join materials through precise thermal conduction and keyhole welding mechanisms, enabling high-speed, deep penetration with minimal distortion. The process uses photonic energy focused by optical components to generate localized heat, creating strong weld seams suitable for metals and thermoplastics. Laser welding offers advantages in automation, repeatability, and the ability to join complex geometries compared to traditional ultrasonic welding methods.

Key Differences Between Ultrasonic and Laser Welding

Ultrasonic welding uses high-frequency mechanical vibrations to join materials, primarily thermoplastics and thin metals, while laser welding employs focused light energy to melt and fuse metals with precision. Ultrasonic welding offers fast cycle times and is ideal for delicate, small components, whereas laser welding provides deeper penetration and stronger joints suitable for thicker and more complex parts. The choice between ultrasonic and laser welding depends on factors such as material type, joint design, production speed, and desired weld strength.

Material Compatibility Comparison

Ultrasonic welding excels in joining thermoplastics like polypropylene, polyethylene, and ABS due to its ability to generate localized heat through high-frequency vibrations, ensuring strong bonds without melting the entire material. Laser welding is more versatile, effectively processing metals such as stainless steel, aluminum, and titanium, and some thermoplastics by focusing precise laser energy to create clean, high-strength joints. Material compatibility for ultrasonic welding favors polymers with good acoustic transmission, whereas laser welding accommodates a broader range of materials, including metals and certain plastics, offering greater flexibility in complex manufacturing applications.

Equipment Setup and Maintenance Requirements

Ultrasonic welding equipment demands precise alignment of the horn and anvil, with regular inspection to ensure consistent amplitude and frequency for optimal weld quality. Laser welding systems require careful calibration of laser power and focus optics, along with routine cleaning of lenses and mirrors to prevent beam distortion. Maintenance for ultrasonic machines is generally simpler and less frequent compared to the more complex, high-precision upkeep needed for laser welding apparatus.

Efficiency and Speed Analysis

Ultrasonic welding offers high efficiency for joining thin, lightweight materials at rapid speeds, typically completing welds in less than a second. Laser welding excels in precision and speed for complex or thicker metal components, achieving weld rates up to several meters per minute with minimal thermal distortion. Comparing both, ultrasonic welding is more energy-efficient for plastics, while laser welding provides faster throughput and better control for metal fabrication tasks.

Quality and Strength of Welds

Ultrasonic welding produces high-quality welds with excellent strength in joining thermoplastics, characterized by minimal thermal distortion and rapid cycle times. Laser welding offers superior precision and deeper penetration for metals, resulting in robust, clean welds with reduced heat-affected zones. Both techniques deliver strong bonds, but laser welding is preferred for complex metal assemblies requiring high strength and fine detail.

Industry Applications and Use Cases

Ultrasonic welding is widely used in electronics assembly, automotive interiors, and medical device manufacturing due to its precision in joining thermoplastics without adhesives or fasteners. Laser welding excels in high-strength metal fabrication, such as aerospace components and automotive chassis, providing deep weld penetration and minimal heat distortion. Both technologies offer specialized solutions tailored to materials and production speed requirements in diverse industrial sectors.

Cost Considerations and ROI Analysis

Ultrasonic welding typically involves lower upfront equipment costs and reduced energy consumption compared to laser welding, making it ideal for high-volume production with minimal operating expenses. Laser welding offers higher precision and flexibility but requires significant capital investment and skilled labor, impacting the initial ROI timeline. Evaluating project scale and material requirements is crucial, as ultrasonic welding delivers faster cost recovery in repetitive tasks, while laser welding suits complex assemblies with longer-term ROI benefits.

Ultrasonic welding vs Laser welding Infographic

productdif.com

productdif.com