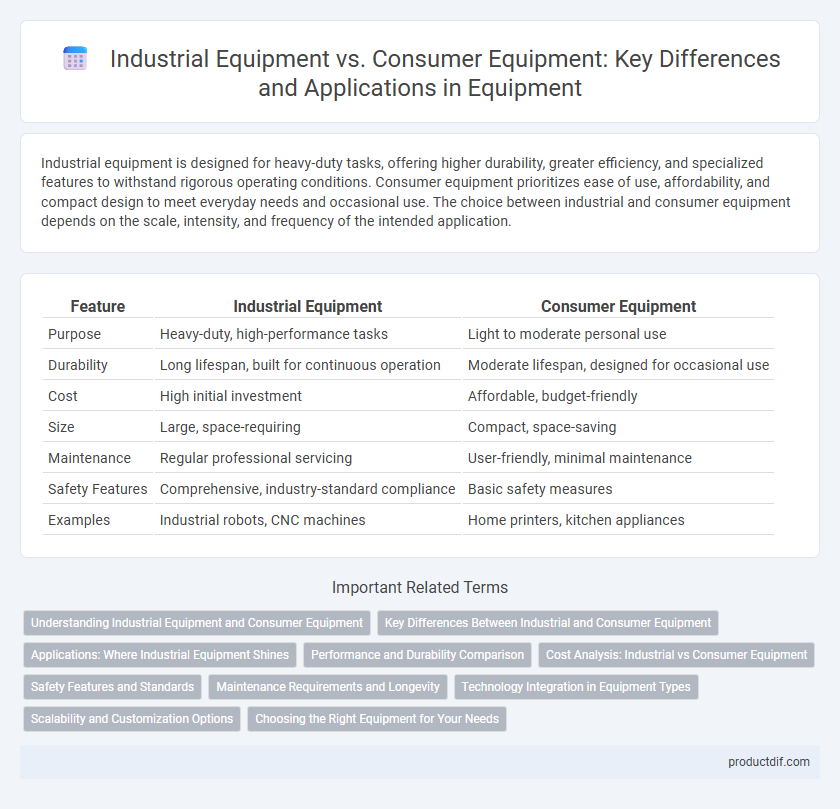

Industrial equipment is designed for heavy-duty tasks, offering higher durability, greater efficiency, and specialized features to withstand rigorous operating conditions. Consumer equipment prioritizes ease of use, affordability, and compact design to meet everyday needs and occasional use. The choice between industrial and consumer equipment depends on the scale, intensity, and frequency of the intended application.

Table of Comparison

| Feature | Industrial Equipment | Consumer Equipment |

|---|---|---|

| Purpose | Heavy-duty, high-performance tasks | Light to moderate personal use |

| Durability | Long lifespan, built for continuous operation | Moderate lifespan, designed for occasional use |

| Cost | High initial investment | Affordable, budget-friendly |

| Size | Large, space-requiring | Compact, space-saving |

| Maintenance | Regular professional servicing | User-friendly, minimal maintenance |

| Safety Features | Comprehensive, industry-standard compliance | Basic safety measures |

| Examples | Industrial robots, CNC machines | Home printers, kitchen appliances |

Understanding Industrial Equipment and Consumer Equipment

Industrial equipment is designed for heavy-duty applications, offering durability, high performance, and compliance with strict safety and regulatory standards specific to manufacturing, construction, and other industrial sectors. Consumer equipment, by contrast, prioritizes ease of use, affordability, and aesthetic appeal, catering to household or personal use with features tailored for convenience and limited operational intensity. Understanding the key differences in design, functionality, and maintenance requirements helps businesses and individuals select appropriate equipment suited to their specific needs and environments.

Key Differences Between Industrial and Consumer Equipment

Industrial equipment is designed for heavy-duty tasks, high durability, and prolonged usage in manufacturing or construction environments, often featuring specialized functions and larger size. Consumer equipment prioritizes user-friendliness, affordability, and compact design suitable for household or personal use with moderate performance requirements. Key differences include build quality, power capacity, intended usage frequency, and compliance with industry-specific safety standards.

Applications: Where Industrial Equipment Shines

Industrial equipment excels in heavy-duty applications such as manufacturing, construction, and energy production due to its robust design, high durability, and capacity for continuous operation under extreme conditions. It is optimized for large-scale processes including assembly lines, heavy lifting, and power generation, where precision and reliability are critical. Consumer equipment, in contrast, is tailored for lighter, everyday tasks and prioritizes ease of use and portability over performance in demanding environments.

Performance and Durability Comparison

Industrial equipment typically delivers higher performance and greater durability compared to consumer equipment, designed to operate continuously under demanding conditions. Heavy-duty materials and advanced engineering in industrial machinery ensure longer service life and resistance to wear, while consumer equipment prioritizes convenience and cost-efficiency for occasional use. Performance metrics such as horsepower, load capacity, and operational hours clearly differentiate industrial-grade tools from their consumer counterparts.

Cost Analysis: Industrial vs Consumer Equipment

Industrial equipment typically entails a higher initial investment due to its robust design, enhanced durability, and specialized functionality, which supports large-scale operations and continuous use. Consumer equipment generally incurs lower upfront costs but may require more frequent replacements and maintenance, potentially increasing long-term expenses. Evaluating total cost of ownership reveals industrial equipment often proves more cost-effective for extensive, demanding applications despite the higher upfront capital.

Safety Features and Standards

Industrial equipment is built to comply with rigorous safety standards such as OSHA and ANSI, incorporating advanced safety features like emergency stop buttons, guardrails, and automatic shut-off systems to protect workers in high-risk environments. Consumer equipment follows regulations like UL and CE certifications, emphasizing user-friendly safety mechanisms including thermal cutoffs, overload protection, and safety interlocks designed for everyday use. The disparity in safety features and standards reflects the distinct operational hazards and regulatory frameworks guiding industrial versus consumer equipment manufacturing.

Maintenance Requirements and Longevity

Industrial equipment demands rigorous maintenance schedules, including frequent inspections, lubrication, and part replacements to ensure continuous operation under heavy-duty conditions. Consumer equipment typically requires less intensive maintenance, often limited to basic cleaning and occasional servicing, reflecting lighter use and lower operational stress. The longevity of industrial equipment significantly surpasses consumer-grade counterparts, as it is engineered with durable materials and designed to withstand high wear and tear over extended periods.

Technology Integration in Equipment Types

Industrial equipment integrates advanced automation, IoT sensors, and AI-driven analytics to optimize performance, enhance safety, and enable predictive maintenance in manufacturing and heavy-duty applications. Consumer equipment, while adopting smart technology such as wireless connectivity and user-friendly interfaces, emphasizes convenience and energy efficiency for everyday use. The technological disparity primarily lies in the complexity and scalability tailored to industrial environments versus the simplicity and accessibility designed for consumer needs.

Scalability and Customization Options

Industrial equipment offers superior scalability and extensive customization options tailored to meet large-scale production demands and specific operational requirements. Consumer equipment typically provides limited scalability with standardized features aimed at general use and ease of operation. The industrial sector benefits from modular designs and advanced integration capabilities, enabling businesses to optimize efficiency and adapt processes swiftly.

Choosing the Right Equipment for Your Needs

Selecting industrial equipment requires prioritizing durability, high performance, and compliance with safety standards to handle intensive, large-scale operations. Consumer equipment is designed for ease of use, affordability, and suitability for lighter, everyday tasks. Understanding the scale and purpose of your project ensures the right balance between cost-efficiency and operational effectiveness in equipment choice.

Industrial equipment vs consumer equipment Infographic

productdif.com

productdif.com