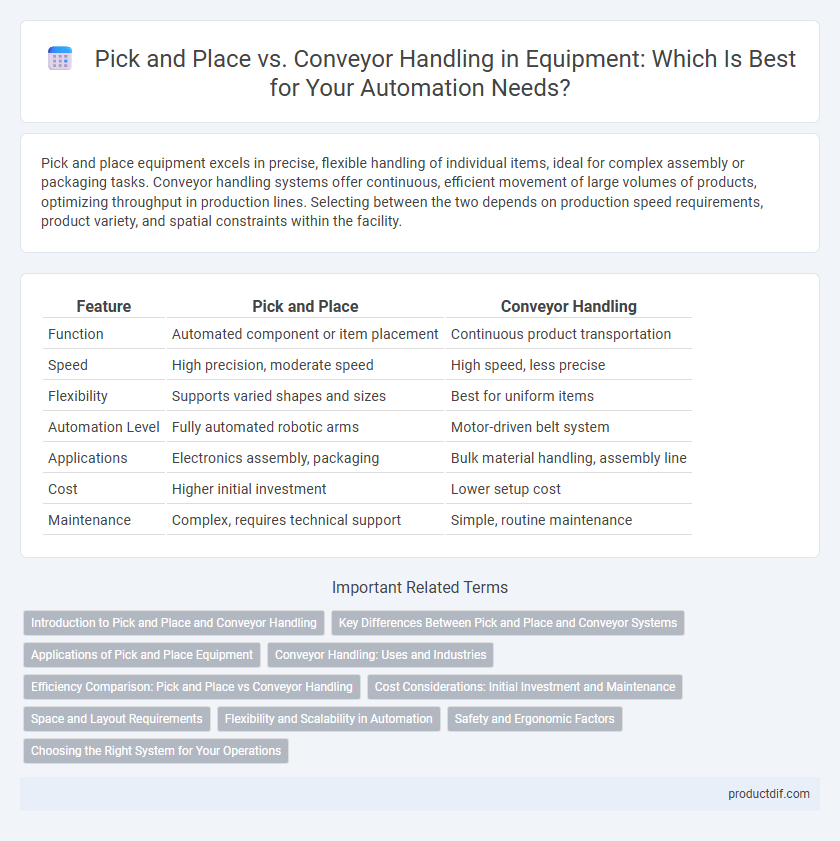

Pick and place equipment excels in precise, flexible handling of individual items, ideal for complex assembly or packaging tasks. Conveyor handling systems offer continuous, efficient movement of large volumes of products, optimizing throughput in production lines. Selecting between the two depends on production speed requirements, product variety, and spatial constraints within the facility.

Table of Comparison

| Feature | Pick and Place | Conveyor Handling |

|---|---|---|

| Function | Automated component or item placement | Continuous product transportation |

| Speed | High precision, moderate speed | High speed, less precise |

| Flexibility | Supports varied shapes and sizes | Best for uniform items |

| Automation Level | Fully automated robotic arms | Motor-driven belt system |

| Applications | Electronics assembly, packaging | Bulk material handling, assembly line |

| Cost | Higher initial investment | Lower setup cost |

| Maintenance | Complex, requires technical support | Simple, routine maintenance |

Introduction to Pick and Place and Conveyor Handling

Pick and place systems automate the movement of components from one location to another with precision, using robotic arms or gantry mechanisms, enhancing production efficiency and accuracy. Conveyor handling involves the continuous transportation of materials or products through a manufacturing or assembly line, improving workflow and reducing manual labor. Both technologies are essential in modern industrial automation, tailored to optimize material flow and processing times depending on production needs.

Key Differences Between Pick and Place and Conveyor Systems

Pick and place systems offer precise, programmable positioning of individual items, ideal for complex assembly tasks requiring high accuracy. Conveyor handling systems provide continuous, automated transport of bulk materials or products along a fixed path, optimized for high-speed, repetitive movement. Key differences include the level of control, flexibility, and application scope, with pick and place excelling in customization and conveyors in throughput efficiency.

Applications of Pick and Place Equipment

Pick and place equipment excels in applications requiring precise, repeatable positioning of components in electronics assembly, packaging, and automotive industries. It is ideal for handling delicate parts, small volumes, and complex product configurations that demand accuracy and speed. This equipment enhances productivity in tasks such as PCB assembly, pharmaceutical packaging, and intricate component sorting where conveyor handling may lack precision.

Conveyor Handling: Uses and Industries

Conveyor handling systems streamline material transport in manufacturing, packaging, and distribution industries, improving efficiency by automating repetitive tasks. Commonly used in automotive assembly, food processing, and pharmaceutical production, these systems support heavy loads and complex product flows with precision. Integration with sensors and robotics enhances real-time tracking and quality control, reducing labor costs and minimizing errors.

Efficiency Comparison: Pick and Place vs Conveyor Handling

Pick and place systems excel in precision and flexibility, allowing efficient handling of small to medium-sized components with minimal errors. Conveyor handling offers continuous movement ideal for high-volume, uniform product flow, significantly reducing cycle times and increasing throughput. Evaluating efficiency depends on the application-specific requirements such as product variability, speed demands, and spatial constraints.

Cost Considerations: Initial Investment and Maintenance

Pick and place equipment typically requires a higher initial investment due to the complexity of robotic arms and control systems, while conveyor handling systems often have lower upfront costs with simpler mechanical components. Maintenance costs for pick and place systems can be more expensive because of the need for specialized parts and skilled technicians, whereas conveyor systems generally incur lower maintenance expenses due to their mechanical simplicity and durability. Evaluating long-term operational expenses and system scalability is crucial for balancing initial investment against ongoing maintenance in automated material handling.

Space and Layout Requirements

Pick and place systems typically require less floor space due to their compact design and flexibility in vertical movement, making them ideal for constrained layouts. Conveyor handling demands a more linear and continuous space allocation, often necessitating longer and wider pathways to accommodate the belt and product flow. Efficient layout planning with pick and place equipment optimizes workspace by minimizing the need for extensive conveyor belt runs and ensuring easy access for maintenance and operation.

Flexibility and Scalability in Automation

Pick and place systems offer exceptional flexibility by easily adapting to different product sizes and complex movements, enabling precise robotic handling for varied automation tasks. Conveyor handling excels in scalability, efficiently managing high-throughput production lines with continuous material flow and minimal manual intervention. Combining both technologies optimizes automation workflows, balancing adaptability with increased processing speed.

Safety and Ergonomic Factors

Pick and place equipment minimizes repetitive strain injuries by automating precise movements, reducing manual handling and ergonomic risks often associated with conveyor systems. Conveyor handling poses safety hazards such as pinch points and entrapment risks, necessitating rigorous guarding and emergency stop features to protect operators. Implementing ergonomic design in pick and place systems enhances operator comfort and productivity, while conveyors require regular risk assessments to mitigate ergonomic fatigue from awkward postures.

Choosing the Right System for Your Operations

Pick and place systems offer precise, flexible positioning ideal for complex assembly tasks, while conveyor handling excels in continuous material flow and high-volume transport efficiency. Selecting the right equipment depends on operational goals such as speed, accuracy, product variety, and workspace layout. Evaluating production demands and integration capabilities ensures optimal automation performance and return on investment.

Pick and place vs Conveyor handling Infographic

productdif.com

productdif.com