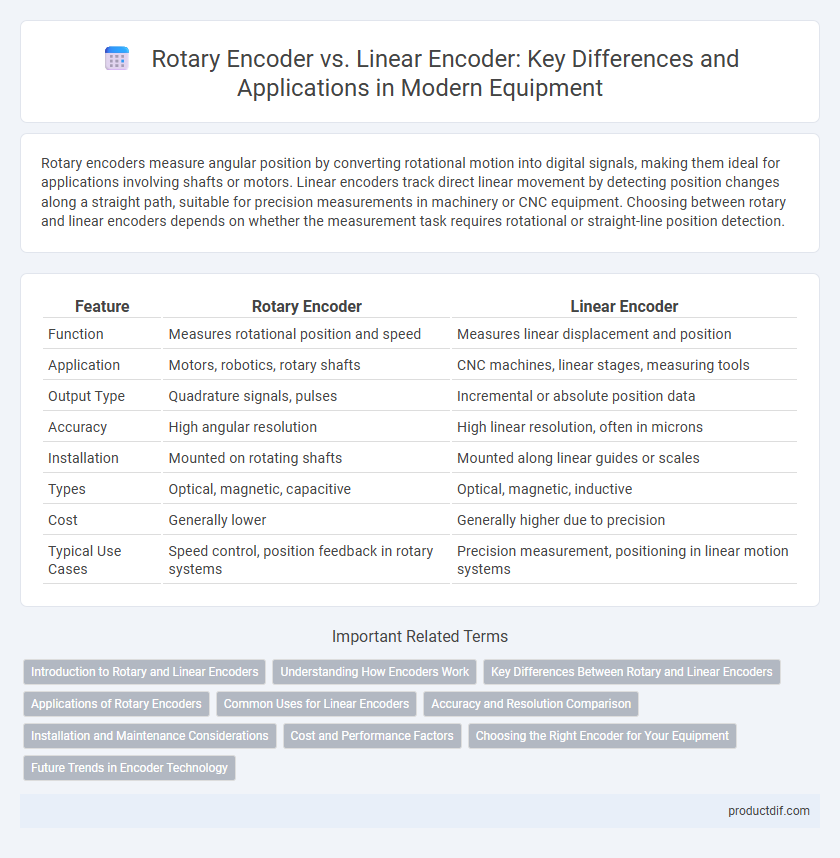

Rotary encoders measure angular position by converting rotational motion into digital signals, making them ideal for applications involving shafts or motors. Linear encoders track direct linear movement by detecting position changes along a straight path, suitable for precision measurements in machinery or CNC equipment. Choosing between rotary and linear encoders depends on whether the measurement task requires rotational or straight-line position detection.

Table of Comparison

| Feature | Rotary Encoder | Linear Encoder |

|---|---|---|

| Function | Measures rotational position and speed | Measures linear displacement and position |

| Application | Motors, robotics, rotary shafts | CNC machines, linear stages, measuring tools |

| Output Type | Quadrature signals, pulses | Incremental or absolute position data |

| Accuracy | High angular resolution | High linear resolution, often in microns |

| Installation | Mounted on rotating shafts | Mounted along linear guides or scales |

| Types | Optical, magnetic, capacitive | Optical, magnetic, inductive |

| Cost | Generally lower | Generally higher due to precision |

| Typical Use Cases | Speed control, position feedback in rotary systems | Precision measurement, positioning in linear motion systems |

Introduction to Rotary and Linear Encoders

Rotary encoders measure angular position or rotational movement by converting mechanical motion into electrical signals, commonly used in motor feedback systems and robotics. Linear encoders provide precise measurement of straight-line displacement, essential for applications in CNC machines and coordinate measuring systems. Both devices utilize optical or magnetic sensing technologies to deliver accurate position feedback, enhancing automation and control in industrial equipment.

Understanding How Encoders Work

Rotary encoders convert angular position into digital signals by detecting shaft rotation using optical or magnetic sensors, enabling precise measurement of rotational motion. Linear encoders track straight-line displacement through a scale and sensor system that reads position changes with high accuracy, essential for applications demanding exact linear positioning. Understanding their operational principles highlights rotary encoders' suitability for rotational measurement and linear encoders' effectiveness in direct linear movement detection.

Key Differences Between Rotary and Linear Encoders

Rotary encoders measure angular position or rotation, converting the mechanical movement of a shaft into digital signals, while linear encoders track straight-line displacement with high precision. Rotary encoders are commonly used in motor feedback systems, robotics, and industrial automation, whereas linear encoders find applications in CNC machines, coordinate measuring machines, and precision metrology. Key differences include measurement type (rotational vs. linear), accuracy levels, installation methods, and typical output signals such as quadrature or incremental for rotary, and absolute or incremental for linear encoders.

Applications of Rotary Encoders

Rotary encoders are widely used in industrial automation for precise position and speed feedback in motors, robotic arms, and CNC machinery. They enable accurate angular displacement measurements, critical for applications such as conveyor systems, packaging equipment, and automotive steering controls. Their reliability and compact design make them ideal for high-speed, repetitive motion monitoring in manufacturing and aerospace technologies.

Common Uses for Linear Encoders

Linear encoders are commonly used in precision measurement applications such as CNC machines, coordinate measuring machines, and semiconductor manufacturing equipment. They provide accurate position feedback by directly measuring linear displacement, enabling precise control in automation and inspection systems. These encoders enhance performance in industries requiring high-resolution positioning and repeatability.

Accuracy and Resolution Comparison

Rotary encoders typically offer high resolution through incremental or absolute measurements, achieving accuracies down to arc-seconds in angular positioning. Linear encoders provide precise positional feedback along a straight path, with resolutions often reaching nanometer scales and accuracies influenced by scale length and environmental factors. When comparing accuracy and resolution, rotary encoders excel in rotational measurement precision, while linear encoders deliver finer resolution and accuracy in linear displacement applications.

Installation and Maintenance Considerations

Rotary encoders generally require precise alignment with rotating shafts, making installation sensitive to angular misalignment and shaft vibration, while linear encoders demand careful mounting along the measurement axis to avoid parallax errors and vibration-induced inaccuracies. Maintenance for rotary encoders often involves monitoring mechanical wear of brushes or optical components, whereas linear encoders require regular inspection of scale cleanliness and protection from dust or coolant ingress. Selecting the appropriate encoder depends on the application's mechanical constraints and environmental conditions to minimize downtime and ensure consistent performance.

Cost and Performance Factors

Rotary encoders typically offer lower cost and are well-suited for applications requiring angle measurement and rotational position feedback, while linear encoders provide higher accuracy and resolution for precise linear positioning tasks. The choice between rotary and linear encoders depends on factors like required measurement range, environmental conditions, and budget constraints, with linear encoders demanding higher investment but delivering superior performance in surface measurement and motion control. Cost efficiency favors rotary encoders in general machinery, whereas industries such as semiconductor manufacturing prioritize the high precision of linear encoders despite their higher cost.

Choosing the Right Encoder for Your Equipment

Selecting the right encoder depends on the motion type and application precision requirements; rotary encoders provide accurate angular position feedback ideal for shafts and rotating equipment, while linear encoders offer precise linear position measurement crucial for straight-line motion control. Consider factors such as resolution, environment, and installation space when choosing between rotary and linear encoders to ensure optimal performance and reliability. Proper encoder selection enhances equipment efficiency, reduces maintenance, and improves overall system accuracy.

Future Trends in Encoder Technology

Future trends in encoder technology emphasize increased integration of artificial intelligence and machine learning algorithms to enhance precision and predictive maintenance in rotary and linear encoders. Miniaturization and the development of non-contact optical and magnetic sensing methods aim to improve durability and reduce wear in industrial applications. Advancements in wireless connectivity and real-time data processing enable smarter, more efficient automation and the expansion of Industry 4.0 ecosystems.

Rotary encoder vs linear encoder Infographic

productdif.com

productdif.com