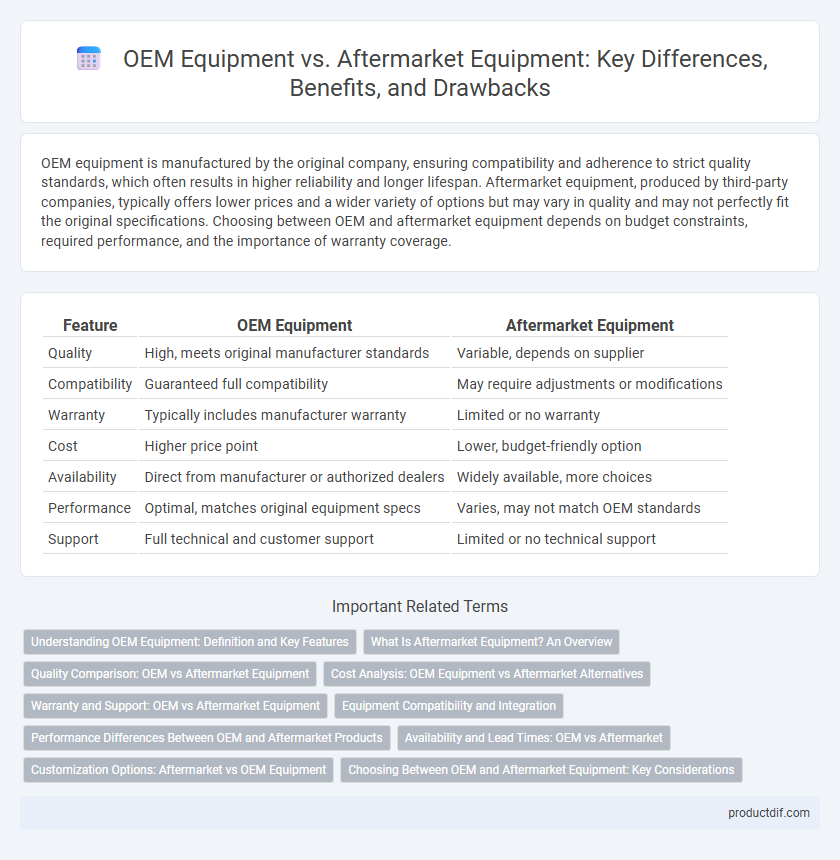

OEM equipment is manufactured by the original company, ensuring compatibility and adherence to strict quality standards, which often results in higher reliability and longer lifespan. Aftermarket equipment, produced by third-party companies, typically offers lower prices and a wider variety of options but may vary in quality and may not perfectly fit the original specifications. Choosing between OEM and aftermarket equipment depends on budget constraints, required performance, and the importance of warranty coverage.

Table of Comparison

| Feature | OEM Equipment | Aftermarket Equipment |

|---|---|---|

| Quality | High, meets original manufacturer standards | Variable, depends on supplier |

| Compatibility | Guaranteed full compatibility | May require adjustments or modifications |

| Warranty | Typically includes manufacturer warranty | Limited or no warranty |

| Cost | Higher price point | Lower, budget-friendly option |

| Availability | Direct from manufacturer or authorized dealers | Widely available, more choices |

| Performance | Optimal, matches original equipment specs | Varies, may not match OEM standards |

| Support | Full technical and customer support | Limited or no technical support |

Understanding OEM Equipment: Definition and Key Features

OEM equipment refers to products manufactured by the original equipment manufacturer, designed specifically to meet the specifications and standards of the original machinery or vehicle. Key features of OEM equipment include guaranteed compatibility, adherence to quality control standards, and often come with manufacturer warranties that ensure reliability and performance. Choosing OEM parts ensures precise fit and durability, reducing the risk of operational issues and maintaining equipment integrity.

What Is Aftermarket Equipment? An Overview

Aftermarket equipment refers to parts and accessories produced by companies other than the original equipment manufacturer (OEM), designed to be compatible with existing machinery or devices. These components often provide cost-effective alternatives to OEM parts while offering customization options and broader availability. Quality and reliability can vary, so it is essential to evaluate aftermarket equipment based on compatibility, performance standards, and warranty coverage.

Quality Comparison: OEM vs Aftermarket Equipment

OEM equipment is designed and manufactured by the original equipment manufacturer, ensuring compatibility, reliability, and adherence to strict quality standards. Aftermarket equipment, produced by third-party suppliers, often varies in quality and may not meet the exact specifications of OEM parts, leading to potential performance issues or reduced durability. Choosing OEM equipment typically guarantees higher consistency and long-term value compared to the more variable quality found in aftermarket alternatives.

Cost Analysis: OEM Equipment vs Aftermarket Alternatives

OEM equipment generally incurs higher upfront costs due to original manufacturer specifications and brand assurance, whereas aftermarket alternatives offer lower initial expenses by providing compatible parts produced by third-party suppliers. Despite the cost difference, OEM equipment often delivers better long-term value with enhanced durability, warranty coverage, and optimized performance, reducing maintenance and replacement frequency. Cost analysis should weigh initial investment against lifecycle expenses, factoring in reliability, parts availability, and potential downtime impacts on operational efficiency.

Warranty and Support: OEM vs Aftermarket Equipment

OEM equipment often comes with manufacturer-backed warranties that guarantee parts and service quality, ensuring reliable support throughout the product's lifecycle. Aftermarket equipment warranties vary widely, frequently offering limited or no coverage, which can result in higher maintenance costs and uncertain support. Choosing OEM equipment provides enhanced peace of mind with consistent warranty terms and direct access to professional technical assistance.

Equipment Compatibility and Integration

OEM equipment ensures seamless compatibility and integration due to its design specifications matching original machinery standards, minimizing risk of operational disruptions. Aftermarket equipment offers flexibility and cost savings but may require additional adjustments or adaptations to achieve full integration, potentially affecting performance consistency. Selecting equipment based on compatibility with existing systems guarantees optimized functionality and reduces maintenance challenges.

Performance Differences Between OEM and Aftermarket Products

OEM equipment guarantees precise compatibility and consistent performance due to strict manufacturing standards and original design specifications. Aftermarket products, while often more affordable, may exhibit variability in quality and durability, potentially impacting equipment efficiency and longevity. Performance differences are influenced by materials, engineering precision, and testing protocols unique to OEM standards.

Availability and Lead Times: OEM vs Aftermarket

OEM equipment typically offers guaranteed availability aligned with manufacturer production schedules but may involve longer lead times due to customization and factory processing. Aftermarket equipment provides greater availability through multiple suppliers with shorter lead times, benefiting urgent repairs and replacements. Choosing between OEM and aftermarket heavily depends on balancing exact fit and quality against immediate access and quicker turnaround times.

Customization Options: Aftermarket vs OEM Equipment

Aftermarket equipment often offers a wider range of customization options compared to OEM equipment, allowing users to tailor components to specific performance or aesthetic requirements. OEM equipment typically provides limited customization but ensures compatibility and adherence to original manufacturer specifications. Selecting between OEM and aftermarket depends on the balance between customization flexibility and guaranteed fitment or warranty protection.

Choosing Between OEM and Aftermarket Equipment: Key Considerations

Choosing between OEM and aftermarket equipment hinges on factors such as quality, cost, warranty, and compatibility with existing systems. OEM equipment guarantees original manufacturer specifications and reliable performance, while aftermarket options often provide cost savings and wider availability. Evaluating long-term maintenance costs, parts availability, and support services is essential to making an informed decision that aligns with operational needs and budget constraints.

OEM Equipment vs Aftermarket Equipment Infographic

productdif.com

productdif.com