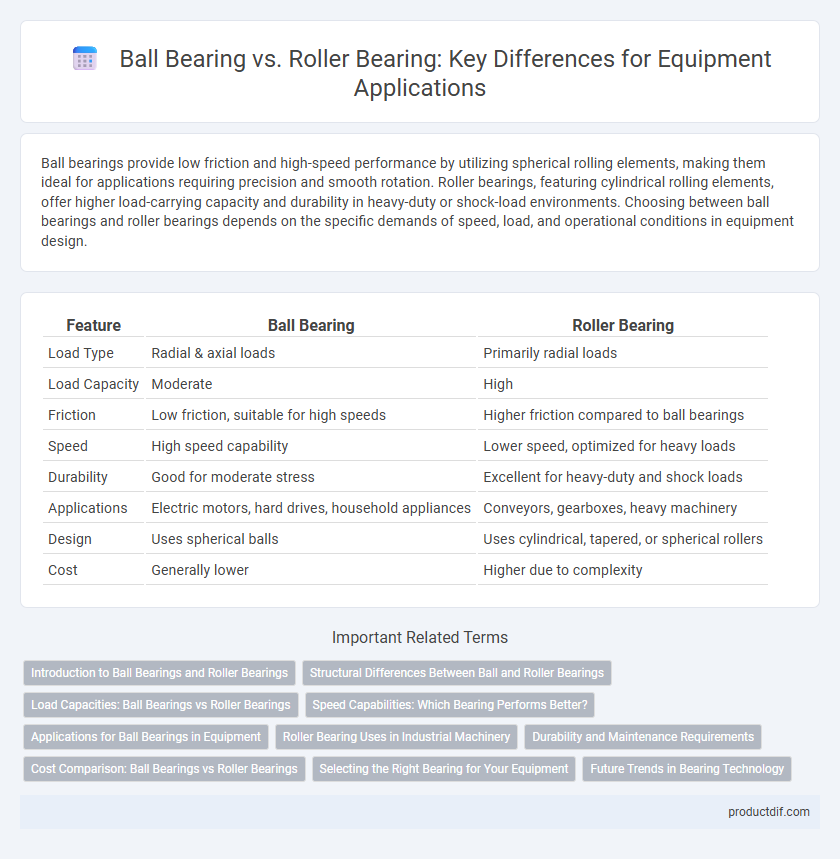

Ball bearings provide low friction and high-speed performance by utilizing spherical rolling elements, making them ideal for applications requiring precision and smooth rotation. Roller bearings, featuring cylindrical rolling elements, offer higher load-carrying capacity and durability in heavy-duty or shock-load environments. Choosing between ball bearings and roller bearings depends on the specific demands of speed, load, and operational conditions in equipment design.

Table of Comparison

| Feature | Ball Bearing | Roller Bearing |

|---|---|---|

| Load Type | Radial & axial loads | Primarily radial loads |

| Load Capacity | Moderate | High |

| Friction | Low friction, suitable for high speeds | Higher friction compared to ball bearings |

| Speed | High speed capability | Lower speed, optimized for heavy loads |

| Durability | Good for moderate stress | Excellent for heavy-duty and shock loads |

| Applications | Electric motors, hard drives, household appliances | Conveyors, gearboxes, heavy machinery |

| Design | Uses spherical balls | Uses cylindrical, tapered, or spherical rollers |

| Cost | Generally lower | Higher due to complexity |

Introduction to Ball Bearings and Roller Bearings

Ball bearings and roller bearings are essential components in machinery, designed to reduce friction between rotating shafts and stationary parts. Ball bearings use spherical balls to facilitate smooth motion and handle radial and axial loads efficiently, making them ideal for high-speed applications. Roller bearings utilize cylindrical, tapered, or spherical rollers to support higher radial loads and provide increased durability in heavy-duty equipment.

Structural Differences Between Ball and Roller Bearings

Ball bearings feature spherical rolling elements that provide point contact with the races, allowing them to handle radial and moderate axial loads with low friction. Roller bearings utilize cylindrical or tapered rollers that create line contact, enhancing load capacity for heavy radial and axial forces. The structural difference in rolling element shape directly impacts load distribution, friction levels, and suitability for varying mechanical applications.

Load Capacities: Ball Bearings vs Roller Bearings

Ball bearings excel in handling radial loads with moderate axial load capacity, making them ideal for high-speed applications with lighter loads. Roller bearings provide significantly higher load capacities, especially under heavy radial loads, due to their larger contact area and line contact design. Choosing between ball and roller bearings depends on load magnitude, direction, and application speed requirements for optimal equipment performance.

Speed Capabilities: Which Bearing Performs Better?

Ball bearings excel in high-speed applications due to their low friction and ability to handle radial and axial loads efficiently, making them ideal for precision instruments and electric motors. Roller bearings, while offering higher load capacity, generally operate at lower speeds because increased friction and heat generation limit their velocity performance. Selecting between ball and roller bearings depends on the specific speed requirements and load conditions of the equipment.

Applications for Ball Bearings in Equipment

Ball bearings are widely used in equipment requiring high-speed rotation and low friction, such as electric motors, hard drives, and precision instruments. Their design supports radial and axial loads, making them ideal for applications in automotive wheels and aerospace components. The compact size and reliability of ball bearings enhance performance in consumer electronics and industrial machinery.

Roller Bearing Uses in Industrial Machinery

Roller bearings are widely utilized in industrial machinery due to their high load-carrying capacity and durability, making them ideal for applications involving heavy radial loads such as conveyor systems, gearboxes, and electric motors. Unlike ball bearings, roller bearings distribute loads over a larger contact area, reducing friction and enhancing machine efficiency in sectors like mining, construction, and manufacturing. Their design accommodates misalignment and shock loads, improving the longevity and performance of industrial equipment.

Durability and Maintenance Requirements

Ball bearings offer high-speed performance with moderate durability, requiring periodic lubrication and occasional replacement of seals to maintain optimal function. Roller bearings provide superior durability under heavy loads and shock conditions, demanding less frequent maintenance but necessitating careful monitoring of alignment and lubrication integrity. Selecting between ball and roller bearings depends on operational load, speed, and maintenance capabilities to ensure long-term equipment reliability.

Cost Comparison: Ball Bearings vs Roller Bearings

Ball bearings generally offer a lower initial cost compared to roller bearings due to simpler design and manufacturing processes. Roller bearings tend to be more expensive but provide higher load capacity and durability, potentially reducing long-term maintenance expenses. Choosing between them depends on balancing upfront costs with performance requirements and operational lifespan.

Selecting the Right Bearing for Your Equipment

Selecting the right bearing for your equipment depends on load capacity, speed, and application type; ball bearings excel in high-speed, low-load scenarios, providing smooth and low-friction performance, while roller bearings handle heavier radial loads and shock impacts effectively. Consider the equipment's operational environment, as roller bearings are more suitable for heavy-duty, industrial machinery, whereas ball bearings fit precision instruments and high-speed applications. Proper bearing selection enhances equipment longevity, reduces maintenance costs, and maximizes efficiency.

Future Trends in Bearing Technology

Future trends in bearing technology emphasize enhanced durability, reduced friction, and increased load capacity through innovations in materials such as ceramics and advanced polymers. Ball bearings continue to evolve with precision manufacturing and smart sensors for predictive maintenance, while roller bearings see improvements in design for heavier loads and high-speed applications. Integration of IoT technology allows real-time monitoring, boosting efficiency and lifespan in industrial equipment.

Ball bearing vs roller bearing Infographic

productdif.com

productdif.com