Cleanroom assembly ensures components are manufactured in controlled environments with minimal contaminants, crucial for high-precision industries like pharmaceuticals and semiconductors. Standard assembly typically takes place in less regulated environments, which may introduce particles or impurities unsuitable for sensitive equipment. Selecting cleanroom assembly optimizes product reliability and performance by maintaining stringent cleanliness standards throughout the manufacturing process.

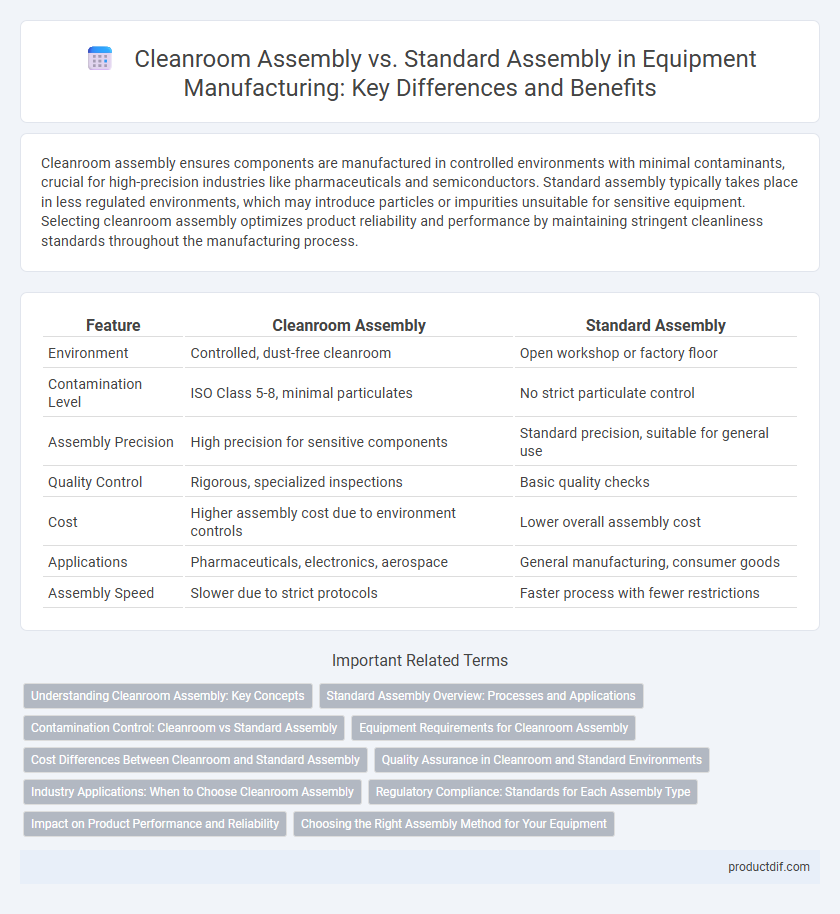

Table of Comparison

| Feature | Cleanroom Assembly | Standard Assembly |

|---|---|---|

| Environment | Controlled, dust-free cleanroom | Open workshop or factory floor |

| Contamination Level | ISO Class 5-8, minimal particulates | No strict particulate control |

| Assembly Precision | High precision for sensitive components | Standard precision, suitable for general use |

| Quality Control | Rigorous, specialized inspections | Basic quality checks |

| Cost | Higher assembly cost due to environment controls | Lower overall assembly cost |

| Applications | Pharmaceuticals, electronics, aerospace | General manufacturing, consumer goods |

| Assembly Speed | Slower due to strict protocols | Faster process with fewer restrictions |

Understanding Cleanroom Assembly: Key Concepts

Cleanroom assembly involves manufacturing processes conducted in controlled environments with low levels of pollutants like dust, airborne microbes, and chemical vapors, which is critical for industries such as pharmaceuticals, semiconductors, and biotechnology. These assemblies use specialized equipment, protective garments, and strict protocols to maintain ISO cleanroom classifications, ensuring product integrity and preventing contamination. Understanding cleanroom assembly requires knowledge of particle control, airflow systems like HEPA filtration, and adherence to regulatory standards such as ISO 14644-1.

Standard Assembly Overview: Processes and Applications

Standard assembly involves the systematic integration of equipment components in environments without stringent contamination controls, making it suitable for general manufacturing applications such as automotive, electronics, and consumer goods production. Key processes include mechanical fastening, soldering, wiring, and functional testing, relying on standard industrial tools and assembly lines. This assembly method emphasizes efficiency and scalability, accommodating large-volume production with moderate quality control measures.

Contamination Control: Cleanroom vs Standard Assembly

Cleanroom assembly ensures stringent contamination control by operating in controlled environments with filtered air, minimizing particulate presence and microbial contamination. Standard assembly lacks these controls, leading to higher risks of dust, debris, and microbial exposure that can compromise sensitive equipment functionality. Optimizing cleanroom processes reduces defects and extends equipment lifespan, critical for industries like semiconductor manufacturing and pharmaceuticals.

Equipment Requirements for Cleanroom Assembly

Cleanroom assembly equipment demands specialized materials and designs that minimize particle generation and contamination risks, such as stainless steel surfaces and HEPA-filtered airflow systems. Precision tools must be non-shedding and resistant to chemical agents commonly used in cleanroom environments. Maintaining stringent environmental controls requires equipment calibrated to meet ISO 14644-1 standards, ensuring particulate and microbial levels remain within acceptable limits.

Cost Differences Between Cleanroom and Standard Assembly

Cleanroom assembly incurs significantly higher costs than standard assembly due to specialized environment controls, contamination prevention measures, and strict regulatory compliance. Equipment and labor expenses increase as cleanrooms require advanced filtration systems, rigorous cleaning protocols, and trained personnel to maintain air quality and minimize particulate presence. These factors cause cleanroom assembly to be 30-50% more expensive, impacting overall project budgets in industries like electronics, pharmaceuticals, and semiconductor manufacturing.

Quality Assurance in Cleanroom and Standard Environments

Cleanroom assembly ensures higher quality assurance by minimizing contamination through controlled environments with filtered air, strict personnel protocols, and continuous monitoring of airborne particles, resulting in reduced product defects and enhanced reliability. Standard assembly environments lack these stringent controls, making them more susceptible to dust, particulate intrusion, and electrostatic discharge, which can compromise sensitive equipment performance. Quality assurance in cleanrooms incorporates rigorous testing and validation processes tailored to maintain ultra-clean conditions, significantly surpassing the quality standards achievable in standard assembly settings.

Industry Applications: When to Choose Cleanroom Assembly

Cleanroom assembly is essential in industries like semiconductor manufacturing, pharmaceuticals, and biotechnology, where contamination control and particle-free environments are critical to product quality and safety. Standard assembly suits applications in automotive, consumer electronics, and heavy machinery, where environmental control is less stringent, and cost-efficiency is prioritized. Selecting cleanroom assembly ensures compliance with stringent industry standards such as ISO 14644 and FDA regulations, minimizing the risk of defects in sensitive components.

Regulatory Compliance: Standards for Each Assembly Type

Cleanroom assembly adheres to stringent regulatory standards like ISO 14644 and GMP guidelines to minimize particulate contamination in sensitive environments. Standard assembly typically follows broader quality standards such as ISO 9001, emphasizing general manufacturing quality without strict environmental controls. Compliance with these specific regulations ensures that cleanroom assembly processes meet critical requirements for industries like pharmaceuticals and semiconductors.

Impact on Product Performance and Reliability

Cleanroom assembly significantly enhances product performance and reliability by minimizing contamination risks and ensuring tighter particulate control. Standard assembly processes may introduce dust, fibers, or other contaminants that degrade sensitive equipment functionality and shorten operational lifespan. Implementing cleanroom standards reduces failure rates and improves consistency in high-precision manufacturing environments.

Choosing the Right Assembly Method for Your Equipment

Cleanroom assembly ensures contamination control by maintaining ISO-certified environments, critical for semiconductor, pharmaceutical, and aerospace equipment requiring particulate-free conditions. Standard assembly suits less sensitive equipment by prioritizing cost-efficiency and faster production without stringent environmental controls. Selecting the right assembly method depends on the equipment's sensitivity to contaminants, industry standards, and required product quality to ensure optimal performance and compliance.

Cleanroom assembly vs standard assembly Infographic

productdif.com

productdif.com