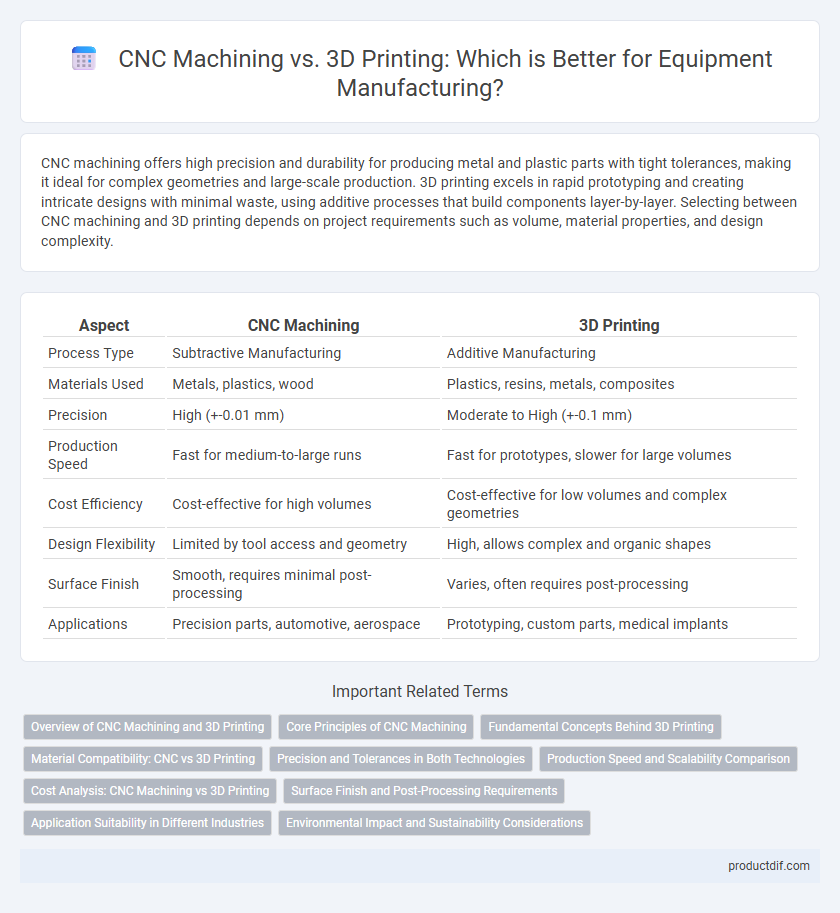

CNC machining offers high precision and durability for producing metal and plastic parts with tight tolerances, making it ideal for complex geometries and large-scale production. 3D printing excels in rapid prototyping and creating intricate designs with minimal waste, using additive processes that build components layer-by-layer. Selecting between CNC machining and 3D printing depends on project requirements such as volume, material properties, and design complexity.

Table of Comparison

| Aspect | CNC Machining | 3D Printing |

|---|---|---|

| Process Type | Subtractive Manufacturing | Additive Manufacturing |

| Materials Used | Metals, plastics, wood | Plastics, resins, metals, composites |

| Precision | High (+-0.01 mm) | Moderate to High (+-0.1 mm) |

| Production Speed | Fast for medium-to-large runs | Fast for prototypes, slower for large volumes |

| Cost Efficiency | Cost-effective for high volumes | Cost-effective for low volumes and complex geometries |

| Design Flexibility | Limited by tool access and geometry | High, allows complex and organic shapes |

| Surface Finish | Smooth, requires minimal post-processing | Varies, often requires post-processing |

| Applications | Precision parts, automotive, aerospace | Prototyping, custom parts, medical implants |

Overview of CNC Machining and 3D Printing

CNC machining uses computer-controlled tools to precisely remove material from a solid block, enabling high accuracy and repeatability for complex parts in metal and plastic. 3D printing builds objects layer by layer from digital models, allowing for rapid prototyping and manufacturing with diverse materials like polymers, metals, and composites. CNC machining excels in tight tolerances and surface finishes, while 3D printing offers design flexibility and reduced waste through additive processes.

Core Principles of CNC Machining

CNC machining operates on the core principle of subtractive manufacturing, where material is precisely removed from a solid block using computer-controlled cutting tools to create intricate and accurate parts. This process relies on G-code programming to dictate tool paths, speeds, and feeds, ensuring high repeatability and tight tolerances essential for metal and plastic component fabrication. Unlike additive 3D printing, CNC machining excels in producing durable, high-strength parts with superior surface finishes, making it ideal for complex prototype and production-grade equipment manufacturing.

Fundamental Concepts Behind 3D Printing

3D printing, also known as additive manufacturing, builds objects layer by layer from digital models using materials such as plastics, metals, or resins. This process contrasts with traditional CNC machining, which involves subtractive techniques that remove material from a solid block to shape the final product. Key advantages of 3D printing include the ability to create complex geometries and reduce material waste, making it ideal for prototyping and low-volume production.

Material Compatibility: CNC vs 3D Printing

CNC machining supports a wide range of materials including metals such as aluminum, steel, and titanium, as well as plastics and composites, making it highly versatile for precision manufacturing. 3D printing primarily utilizes polymers, resins, and certain metal powders, with limitations in material strength and thermal resistance compared to CNC-machined parts. Material compatibility in CNC machining enables production of durable components for aerospace and automotive industries, whereas 3D printing excels in rapid prototyping and complex geometries with lightweight materials.

Precision and Tolerances in Both Technologies

CNC machining delivers exceptional precision with tolerances often within +-0.01 mm, making it ideal for high-accuracy metal and plastic components. 3D printing typically offers less consistent tolerance control, generally around +-0.1 mm, due to layer-by-layer additive processes and material limitations. For applications demanding ultra-fine detail and tight dimensional control, CNC machining remains the preferred choice, while 3D printing excels in rapid prototyping with moderately precise tolerances.

Production Speed and Scalability Comparison

CNC machining offers faster production speeds for high-volume runs due to automated cutting and milling processes, making it ideal for large-scale manufacturing. 3D printing excels in rapid prototyping and small-batch production, but slower layer-by-layer construction limits scalability for mass production. Scalability in CNC machining is enhanced by repeatability and minimal post-processing, whereas 3D printing requires longer build times and often additional finishing for each unit.

Cost Analysis: CNC Machining vs 3D Printing

CNC machining typically incurs higher initial setup costs due to tooling and programming, but offers lower per-unit costs for large production runs, making it cost-effective for mass manufacturing. In contrast, 3D printing involves minimal setup expenses and excels in producing complex, low-volume parts economically, but its per-unit cost remains relatively high for large volumes. Analyzing cost drivers such as material waste, labor, and production speed highlights CNC machining's advantage in scalability compared to the flexibility of 3D printing.

Surface Finish and Post-Processing Requirements

CNC machining delivers superior surface finish with tighter tolerances due to precise cutting tools, minimizing the need for extensive post-processing. 3D printing often results in layered textures that require smoothing techniques such as sanding or chemical treatments to achieve comparable surface quality. Post-processing for CNC parts is usually limited to deburring and polishing, whereas 3D printed components demand additional finishing steps to improve aesthetics and functionality.

Application Suitability in Different Industries

CNC machining excels in manufacturing high-precision metal components for aerospace, automotive, and medical industries due to its ability to handle complex geometries and tight tolerances. 3D printing is ideal for rapid prototyping, custom product development, and producing intricate plastic parts in industries like consumer goods, healthcare, and aerospace. Both technologies serve complementary roles, with CNC machining favored for durability and large-scale production, while 3D printing enables flexibility and quick iteration.

Environmental Impact and Sustainability Considerations

CNC machining generates more industrial waste and consumes higher energy levels compared to 3D printing, which produces minimal scrap material and allows for on-demand manufacturing. 3D printing supports sustainable production by reducing raw material usage and enabling recycling of certain polymers, while CNC machining relies heavily on metal stock and coolant fluids that can pose environmental hazards. Sustainable manufacturing strategies increasingly favor 3D printing for its lower carbon footprint, waste reduction, and ability to optimize material efficiency in complex components.

CNC machining vs 3D printing Infographic

productdif.com

productdif.com