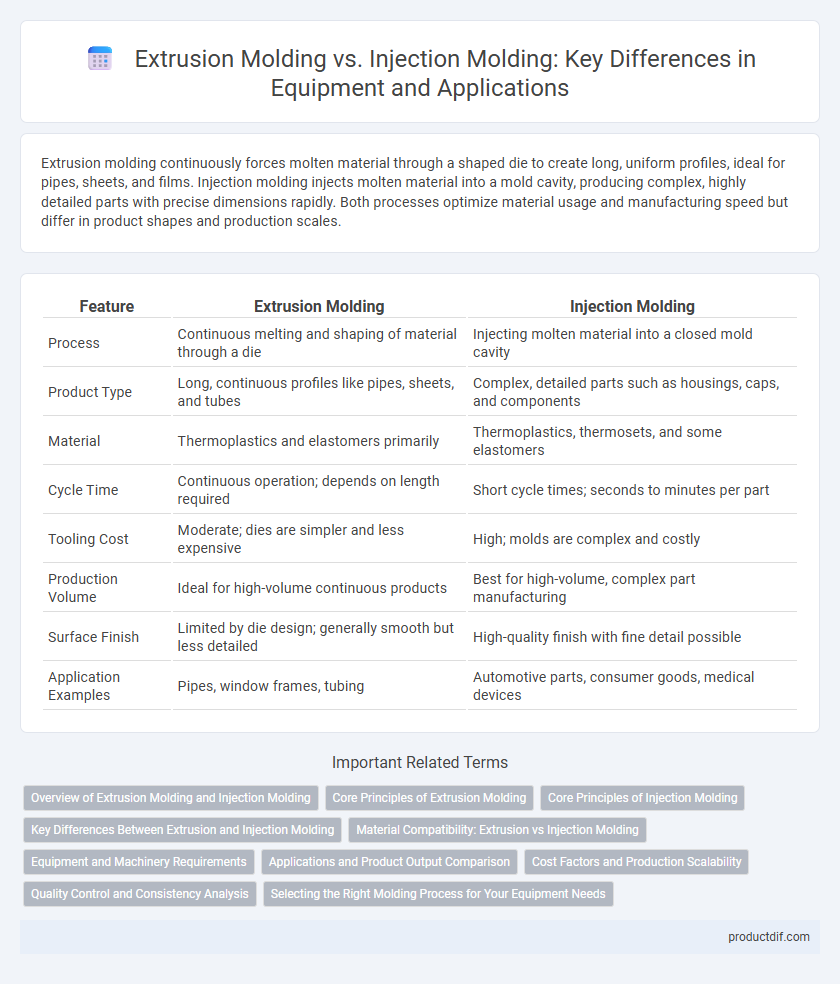

Extrusion molding continuously forces molten material through a shaped die to create long, uniform profiles, ideal for pipes, sheets, and films. Injection molding injects molten material into a mold cavity, producing complex, highly detailed parts with precise dimensions rapidly. Both processes optimize material usage and manufacturing speed but differ in product shapes and production scales.

Table of Comparison

| Feature | Extrusion Molding | Injection Molding |

|---|---|---|

| Process | Continuous melting and shaping of material through a die | Injecting molten material into a closed mold cavity |

| Product Type | Long, continuous profiles like pipes, sheets, and tubes | Complex, detailed parts such as housings, caps, and components |

| Material | Thermoplastics and elastomers primarily | Thermoplastics, thermosets, and some elastomers |

| Cycle Time | Continuous operation; depends on length required | Short cycle times; seconds to minutes per part |

| Tooling Cost | Moderate; dies are simpler and less expensive | High; molds are complex and costly |

| Production Volume | Ideal for high-volume continuous products | Best for high-volume, complex part manufacturing |

| Surface Finish | Limited by die design; generally smooth but less detailed | High-quality finish with fine detail possible |

| Application Examples | Pipes, window frames, tubing | Automotive parts, consumer goods, medical devices |

Overview of Extrusion Molding and Injection Molding

Extrusion molding continuously forces heated material through a shaped die to create long, uniform products like pipes or sheets, optimizing production for consistent cross-sectional profiles. Injection molding involves injecting molten material into a precise mold cavity, producing complex, high-precision parts with rapid cycle times ideal for mass production of intricate components. Both methods use thermoplastics but serve distinct manufacturing needs based on product geometry and production volume.

Core Principles of Extrusion Molding

Extrusion molding involves forcing molten material through a shaped die to create continuous profiles with consistent cross-sections, ideal for producing pipes, sheets, and films. The process relies on a screw or ram to push the melted polymer through the die, maintaining steady pressure and temperature for uniform flow and material properties. Unlike injection molding, extrusion molding specializes in continuous production rather than discrete parts, emphasizing constant material feed and precise die design for efficiency.

Core Principles of Injection Molding

Injection molding operates by injecting molten material into a mold cavity under high pressure, enabling complex geometries with precise dimensional accuracy and smooth surface finishes. The core principle involves rapid cooling and solidification within the mold, resulting in high production efficiency and consistent part quality. This process excels in producing high-volume, intricate components from thermoplastics, thermosets, and elastomers, offering superior repeatability compared to extrusion molding.

Key Differences Between Extrusion and Injection Molding

Extrusion molding continuously produces uniform cross-sectional profiles by forcing melted material through a shaped die, optimal for pipes, films, and sheets, while injection molding injects molten plastic into a mold cavity to form complex, detailed parts with high precision. Extrusion molding offers continuous production with lower tooling costs, whereas injection molding enables rapid production of intricate, high-volume components with tighter tolerances. Material viscosity requirements and cooling times also differ, with extrusion favoring thermoplastics and injection molding accommodating a broader range of polymers and multi-material blends.

Material Compatibility: Extrusion vs Injection Molding

Extrusion molding excels in processing thermoplastic materials with consistent profiles, such as polyethylene and PVC, allowing continuous production of pipes, sheets, and films. Injection molding provides superior versatility in material compatibility, accommodating a broad range of thermoplastics, thermosets, and elastomers like ABS, nylon, and silicone for complex and precise components. Material viscosity and thermal properties critically influence the choice between extrusion and injection molding to ensure optimal product quality and manufacturing efficiency.

Equipment and Machinery Requirements

Extrusion molding requires continuous, high-capacity screw machines designed for consistent melting and shaping of thermoplastic materials, making it ideal for long, uniform profiles. Injection molding demands more complex machinery with precise temperature control and high-pressure injection units to produce detailed, intricate parts with tight tolerances. Both equipment types rely heavily on robust clamping systems and customized molds, but injection molding machines typically have higher maintenance needs due to their complex hydraulic and electronic controls.

Applications and Product Output Comparison

Extrusion molding is ideal for producing continuous shapes like pipes, sheets, and tubing, offering consistent wall thickness and high-volume output with uniform cross-sections. Injection molding excels in manufacturing complex, detailed parts such as automotive components, consumer electronics housings, and medical devices, delivering precise dimensions and smooth surface finishes. While extrusion provides efficient production of long, continuous profiles, injection molding enables rapid fabrication of intricate, high-strength parts with tight tolerances.

Cost Factors and Production Scalability

Extrusion molding offers lower tooling costs and faster setup times, making it cost-effective for continuous production runs of standardized profiles. Injection molding involves higher initial tooling investment but supports complex geometries and high-volume production with exceptional repeatability. Production scalability favors extrusion for long-length parts and injection molding for high-precision, high-volume batch outputs.

Quality Control and Consistency Analysis

Extrusion molding ensures consistent cross-sectional profiles by maintaining continuous material flow through a fixed die, enabling uniform quality in long production runs, while injection molding offers precise control over part dimensions through automated injection pressure and temperature regulation, critical for complex, high-precision components. Quality control in extrusion molding relies heavily on real-time monitoring of melt temperature and screw speed to detect deviations that affect product consistency, whereas injection molding employs statistical process control (SPC) and in-mold sensors to identify defects like short shots or flash before production completion. Both methods benefit from advanced analytics and machine learning algorithms that predict process variations, optimize parameters, and maintain stringent tolerances to enhance product reliability and reduce waste.

Selecting the Right Molding Process for Your Equipment Needs

Extrusion molding is ideal for producing continuous profiles such as pipes, tubing, and sheets, offering high efficiency for long, uniform shapes. Injection molding excels in manufacturing complex, precise parts with intricate geometries and rapid production cycles, suitable for high-volume equipment components. Evaluating product design, production volume, and material compatibility ensures optimal selection between extrusion and injection molding for equipment manufacturing.

Extrusion molding vs Injection molding Infographic

productdif.com

productdif.com