Prototyping allows for testing and refining equipment designs on a small scale, enabling rapid iteration and problem-solving before full-scale manufacturing. Mass production focuses on efficiency and cost-effectiveness by producing large quantities of equipment with consistent quality and standardized processes. Choosing between prototyping and mass production depends on project goals, timeline, and budget constraints.

Table of Comparison

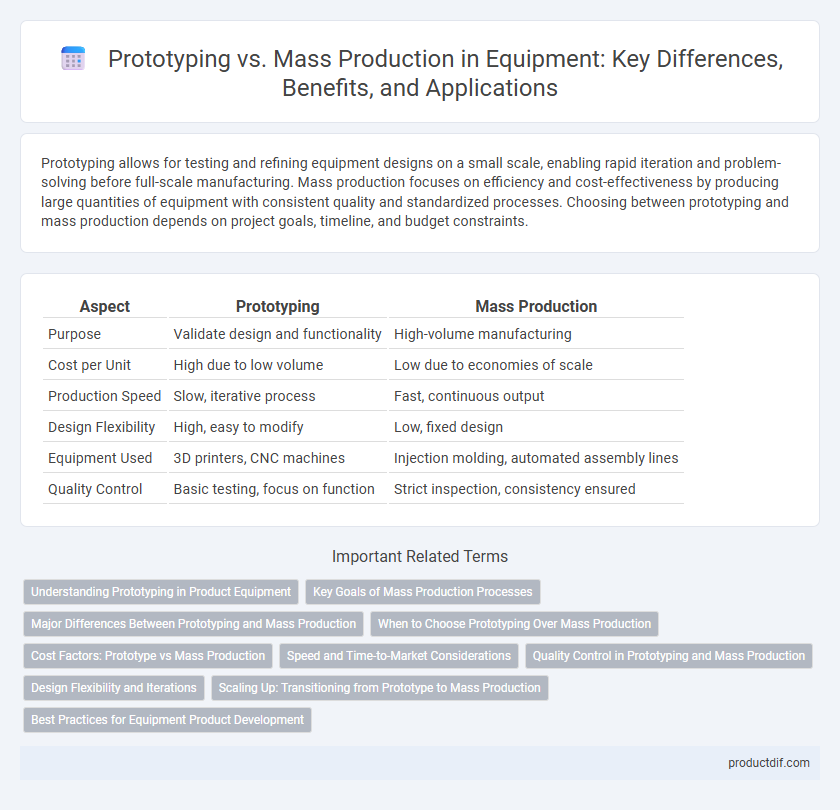

| Aspect | Prototyping | Mass Production |

|---|---|---|

| Purpose | Validate design and functionality | High-volume manufacturing |

| Cost per Unit | High due to low volume | Low due to economies of scale |

| Production Speed | Slow, iterative process | Fast, continuous output |

| Design Flexibility | High, easy to modify | Low, fixed design |

| Equipment Used | 3D printers, CNC machines | Injection molding, automated assembly lines |

| Quality Control | Basic testing, focus on function | Strict inspection, consistency ensured |

Understanding Prototyping in Product Equipment

Prototyping in product equipment involves creating a preliminary model to test design concepts, functionality, and usability before full-scale manufacturing. This process enables identification of potential flaws and design improvements, reducing costly errors during mass production. Rapid prototyping technologies like 3D printing and CNC machining accelerate development cycles and ensure precise replication of components.

Key Goals of Mass Production Processes

Mass production processes focus on achieving high efficiency, consistent quality, and cost reduction through standardized equipment and automation. Key goals include optimizing throughput rates, minimizing downtime, and ensuring repeatable precision in every unit produced. Implementing scalable machinery and streamlined workflows drives economies of scale and meets large-volume demand effectively.

Major Differences Between Prototyping and Mass Production

Prototyping involves creating a limited number of models to test design concepts and functionality, emphasizing flexibility and iterative improvements. Mass production focuses on manufacturing large volumes of uniform products efficiently, prioritizing consistency, cost reduction, and speed. Major differences include scale, customization level, production time, and cost per unit, where prototyping is slower and more expensive per item, while mass production achieves economies of scale with standardized outputs.

When to Choose Prototyping Over Mass Production

Prototyping is ideal when testing new equipment designs to identify flaws and improve functionality before large-scale manufacturing. It allows for cost-effective iterations and customization, reducing risks associated with mass production errors. Choose prototyping when innovation, precision, and validation are critical to product success.

Cost Factors: Prototype vs Mass Production

Prototype development incurs higher per-unit costs due to limited scale, custom materials, and extensive testing requirements. Mass production lowers costs significantly through economies of scale, streamlined manufacturing processes, and bulk purchasing of raw materials. Understanding fixed and variable expenses helps optimize budget allocation between prototype iteration and large-scale equipment fabrication.

Speed and Time-to-Market Considerations

Prototyping accelerates innovation by enabling rapid design iterations and early testing, significantly reducing time-to-market for new equipment concepts. Mass production prioritizes efficiency and consistency but requires longer lead times to set up tooling and manufacturing processes, potentially delaying product launch. Balancing quick prototyping cycles with streamlined mass production strategies is crucial for optimizing speed without compromising quality.

Quality Control in Prototyping and Mass Production

Quality control in prototyping focuses on identifying design flaws and performance issues through rigorous testing and iterative adjustments, ensuring the initial product concept meets specifications before scaling. In mass production, quality control emphasizes consistency and defect prevention, implementing standardized processes and automated inspections to maintain uniformity across large volumes. Advanced statistical process control (SPC) and real-time monitoring systems play crucial roles in sustaining high-quality outputs throughout the manufacturing lifecycle.

Design Flexibility and Iterations

Prototyping allows for high design flexibility and multiple iterations, enabling engineers to refine equipment specifications and functionality before finalizing. Mass production prioritizes efficiency and consistency, limiting the ability to implement significant design changes once the process begins. Early-stage prototyping reduces costly errors and optimizes performance by accommodating iterative adjustments in the equipment design.

Scaling Up: Transitioning from Prototype to Mass Production

Scaling up from prototyping to mass production involves refining equipment design for consistency, durability, and cost-efficiency to meet high volume demands. Industrial-grade machinery and automated assembly lines replace manual, low-volume prototyping tools to increase throughput and maintain quality standards. Effective transition requires rigorous testing, supply chain optimization, and integration of quality control systems to ensure scalability without compromising product integrity.

Best Practices for Equipment Product Development

Selecting the right approach between prototyping and mass production hinges on equipment functionality validation and scalability assessment. Rapid prototyping employs 3D printing and CNC machining to create precise models for rigorous testing and iterative design improvements. Mass production leverages injection molding and automated assembly lines to ensure cost-effective manufacturing, uniform quality, and high-volume output in finalized equipment products.

Prototyping vs Mass Production Infographic

productdif.com

productdif.com