Standard equipment offers cost-effective, reliable solutions designed to meet general industry requirements, ensuring compatibility and ease of maintenance. Custom equipment provides tailored functionality and specifications to address unique operational challenges, enhancing performance and efficiency for specialized tasks. Choosing between standard and custom equipment depends on balancing budget constraints with the need for specific features and flexibility.

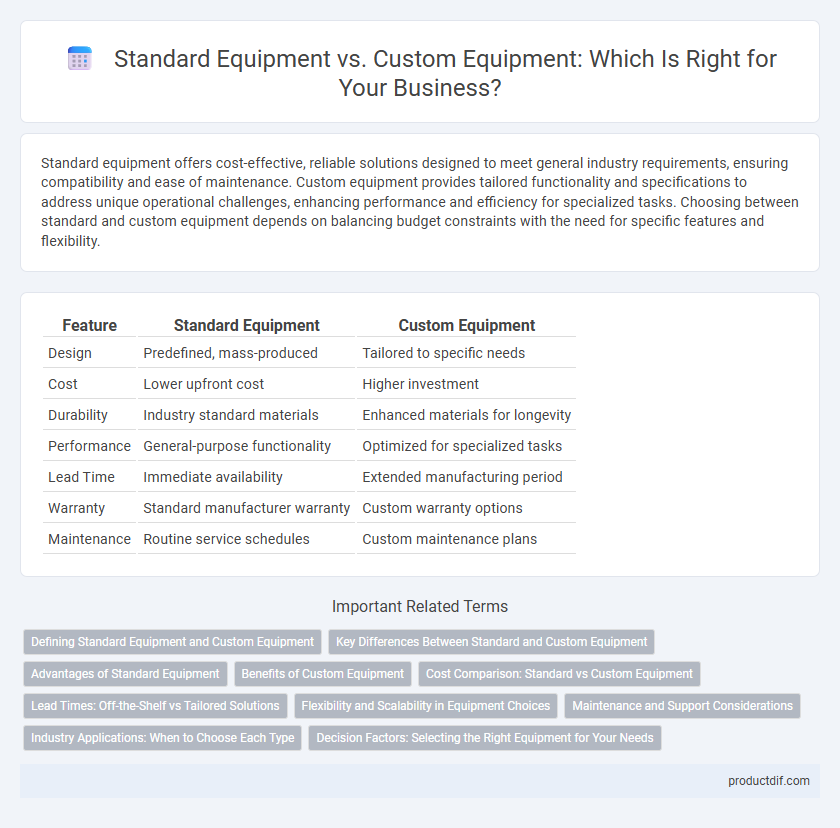

Table of Comparison

| Feature | Standard Equipment | Custom Equipment |

|---|---|---|

| Design | Predefined, mass-produced | Tailored to specific needs |

| Cost | Lower upfront cost | Higher investment |

| Durability | Industry standard materials | Enhanced materials for longevity |

| Performance | General-purpose functionality | Optimized for specialized tasks |

| Lead Time | Immediate availability | Extended manufacturing period |

| Warranty | Standard manufacturer warranty | Custom warranty options |

| Maintenance | Routine service schedules | Custom maintenance plans |

Defining Standard Equipment and Custom Equipment

Standard equipment refers to the factory-installed components and features that come pre-configured with a product, ensuring baseline functionality and compliance with industry regulations. Custom equipment involves tailored modifications or additions designed to meet specific operational needs, providing enhanced performance or unique capabilities beyond standard offerings. Understanding the distinction helps businesses optimize procurement strategies and align equipment functionality with precise application requirements.

Key Differences Between Standard and Custom Equipment

Standard equipment offers pre-designed, mass-produced features that ensure compatibility and cost-efficiency for general applications. Custom equipment is tailored to specific operational requirements, providing enhanced performance, scalability, and unique functionalities. The key differences lie in design flexibility, lead time, and overall investment, with custom equipment typically requiring higher initial costs but delivering optimized solutions.

Advantages of Standard Equipment

Standard equipment offers consistent reliability and proven performance due to rigorous testing and industry-wide adoption. It ensures cost-effectiveness by reducing manufacturing expenses and simplifying maintenance with readily available parts. Furthermore, standard equipment supports seamless integration and compatibility across various systems, enhancing operational efficiency.

Benefits of Custom Equipment

Custom equipment offers tailored solutions that precisely meet specific operational requirements, enhancing efficiency and productivity. It provides flexibility in design, allowing integration of unique features and advanced technology that standard equipment may lack. By aligning perfectly with business needs, custom equipment minimizes downtime and maintenance costs, delivering long-term value and competitive advantage.

Cost Comparison: Standard vs Custom Equipment

Standard equipment generally offers lower upfront costs due to mass production and established supply chains, making it more budget-friendly for most businesses. Custom equipment involves higher initial investment because of tailored design, specialized materials, and unique manufacturing processes, which can significantly increase expenses. Long-term cost efficiency depends on the specific application, with custom equipment potentially reducing operational costs through enhanced performance and durability.

Lead Times: Off-the-Shelf vs Tailored Solutions

Standard equipment offers significantly shorter lead times, often available for immediate shipment due to mass production and established inventory. Custom equipment requires extended lead times as it involves design, engineering, and manufacturing tailored to specific client specifications, which can range from weeks to several months. Businesses must balance the urgency of deployment with the need for specialized features when choosing between off-the-shelf and bespoke solutions.

Flexibility and Scalability in Equipment Choices

Standard equipment offers predictable performance and cost-efficiency, making it ideal for operations with stable and well-defined needs. Custom equipment provides enhanced flexibility and scalability, allowing businesses to tailor solutions to evolving demands and integrate advanced features for future growth. Choosing between standard and custom equipment depends on balancing immediate budget constraints against long-term adaptability and expansion potential.

Maintenance and Support Considerations

Standard equipment typically offers streamlined maintenance and readily available support due to established service protocols and widespread parts availability. Custom equipment may require specialized maintenance expertise and longer downtime for repairs, as parts and support are often unique and less accessible. Evaluating long-term support infrastructure and maintenance costs is critical when choosing between standard and custom equipment solutions.

Industry Applications: When to Choose Each Type

Standard equipment suits industries with consistent, high-volume production needs, offering reliability and cost-efficiency through proven designs. Custom equipment is ideal for specialized applications requiring tailored functionality, unique specifications, or integration with existing systems in sectors like aerospace, pharmaceuticals, and specialized manufacturing. Choosing between standard and custom equipment depends on factors such as production scale, complexity of processes, and the need for flexibility in meeting industry-specific standards.

Decision Factors: Selecting the Right Equipment for Your Needs

Choosing between standard equipment and custom equipment hinges on factors such as project specifications, budget constraints, and time availability. Standard equipment offers cost-efficiency and quicker deployment, ideal for common applications with predictable requirements. Custom equipment provides tailored functionality and enhanced performance for specialized tasks, justifying higher upfront investment and longer lead times when unique operational demands exist.

Standard equipment vs custom equipment Infographic

productdif.com

productdif.com